KCl drying: Potash is typically rich in potassium chloride (KCl), sodium chloride (NaCl) and other salts, and is obtained by dissolution mining and evaporation methods from brines.

Approximately 95% of potash production is fertilizer used for agricultural purposes. The most common form of potash fertilizer is potassium chloride (KCl) but can also include potassium carbonate (K2CO3), potassium sulfate (K2SO4), or potassium nitrate (KNO3). After potash is mined it is processed to create a commercial product.

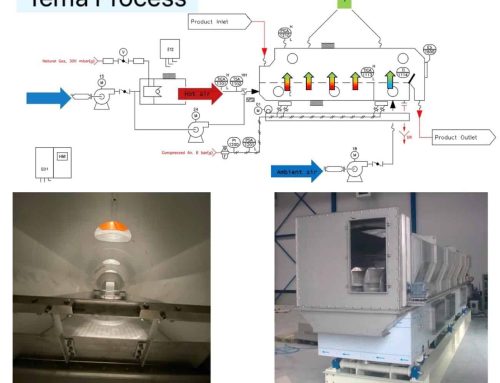

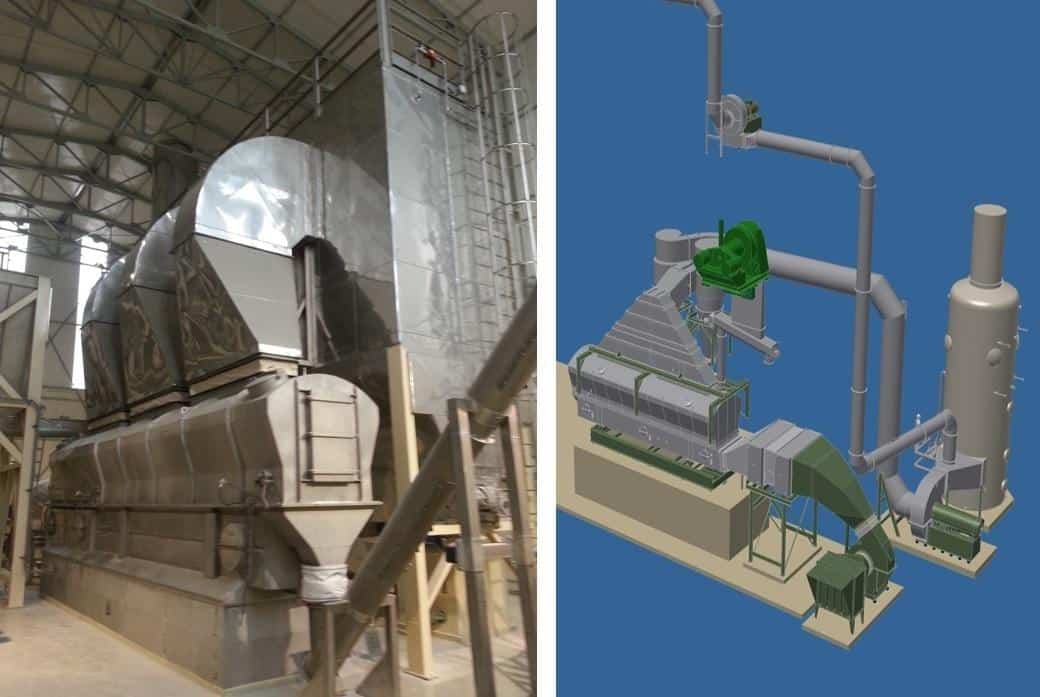

Potash drying in a fluid bed dryer is an essential part of the process. Drying and cooling of the KCl fine product and granules can be achieved in one fluid bed system. The exhaust gasses of the dryer/cooler can contain fines. These fines can be removed by : 1. Jetbag filter 2. cylones and a wet scrubber or 3. a Venturi in combination with a wet scrubber.

![Shipping dryers [video]](https://temaprocess.com/wp-content/uploads/2020/08/shipping-dryers-500x383.png)

![Increasing production capacity [video]](https://temaprocess.com/wp-content/uploads/2020/06/Increasing-production-capacity-video-500x383.png)

![Fluid bed dryers for spray drying [video]](https://temaprocess.com/wp-content/uploads/2020/06/Fluid-bed-dryers-for-spray-drying-500x383.png)