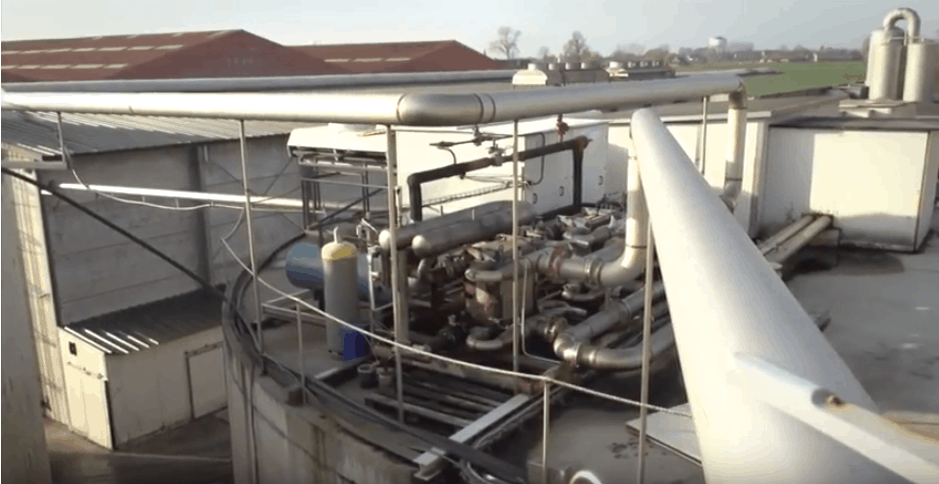

Digestate Dryer: AM Power is located in the western part of Flanders (Belgium), a region characterized by an excess of animal manure and yet a high market demand for formulated synthetic fertilizer. The plant is one of the largest biogas installations in Belgium: it has a treatment capacity of 180 kt/y spread over five digesters, for the production of 7.5 MW of electricity. The co-digestion plant treats about 180 kt of feedstock every year out of which almost 90% is organic biological waste (i.e. food waste). Co-substrates include animal manure and energy maize. Biogas production: The biogas is converted by a CHP engine into electrical and thermal energy. Nutrient Recovery and Reuse (NRR) Technology, currently the process works . Homogenized feedstock is hydrolysed in a separate units and fed to a thermophilic digester. • Digestate (9% dry matter, DM) is sent to a centrifuge for solid/liquid separation. • The solid fraction that contains 90-95% of the initially separated total phosphorous (P) is dried on a Tema Process fluid bed dryer while the liquid fraction is sent to a flotation and reverse osmosis (RO) unit. Drying of solid fraction is accomplished by recycling waste heat from CHP engines.