Bentonite (clay) dryer: Bentonite is the commercial name of a whole range of natural clays with a high water absorption capacity causing it to expand and swell. Bentonites may contain in addition a variety of accessory minerals. These may include lesser amounts of other clay minerals such as kaolin, mica, illite, as well as non-clay minerals like quartz, feldspar, calcite, and gypsum.

Uses: purification, drilling mud, binder, foundry, paper, cat litter, etc.

There are also different varieties of bentonite clay with different concentrations of minerals.

There are three types of bentonite clay;

- calcium bentonite

- sodium bentonite

- potassium bentonite

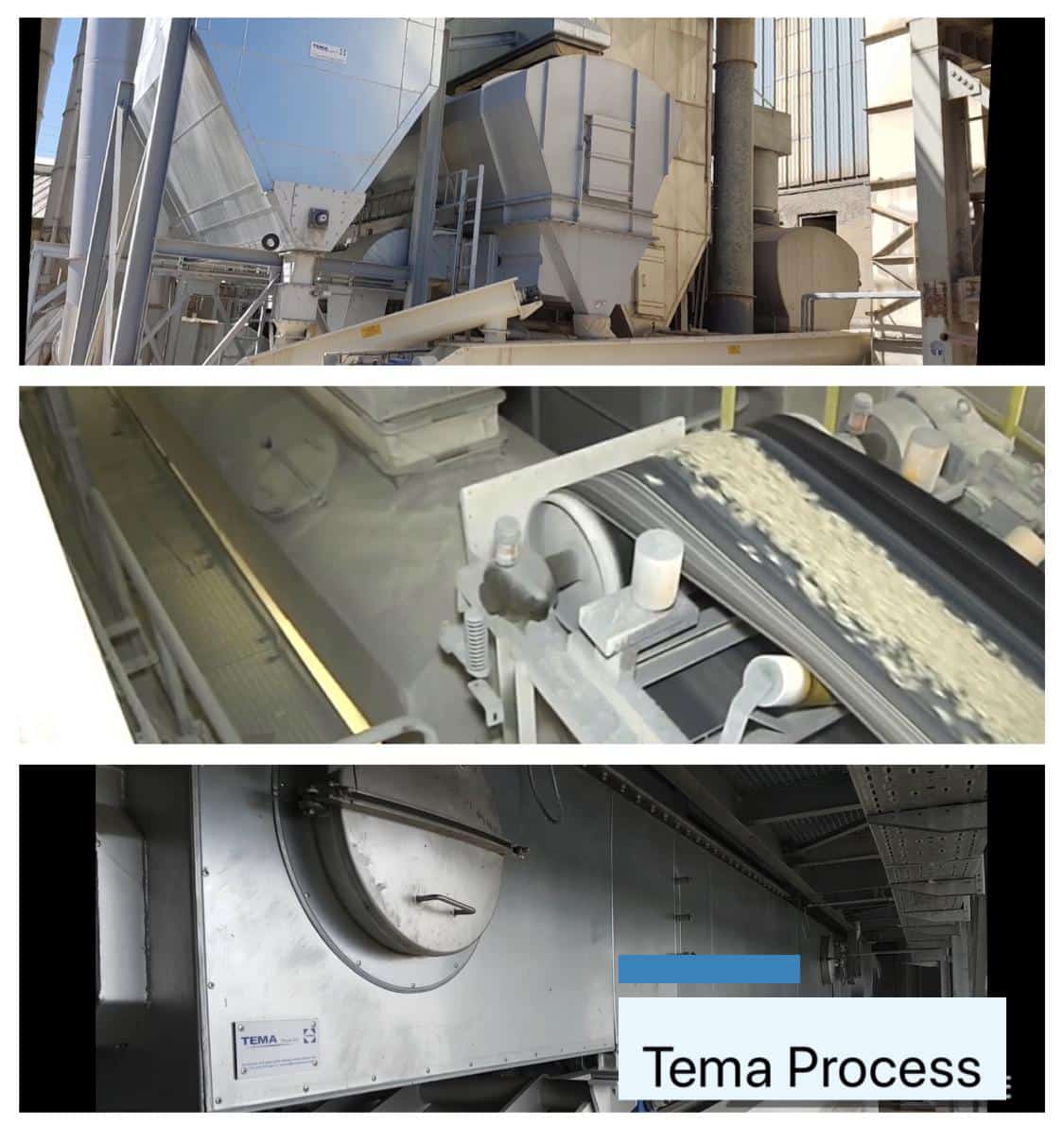

It can be applied to all kinds of extruded and granular materials with a high water content. The fluid bed dryer by Tema Process integrates drying and cooling into a single unit. The dryer moves the product from inlet to discharge in a first-in, first-out process. The granules or extruded clay of require the dryer to be run at a high air velocity. The puls-jet dust collector captures the fine clay particles entrained in the process air stream and automatically returns (optional) the particles into the process.