Drying citrus peel is the first step of utilizing that by-product in the food and feed industry. Much of the pulp is dried and exported around the world. It is easier to haul and manage and can be stored year-round. Drying is usually done at the fruit processing site to save on transportation costs

Citrus pulp is used as a cereal substitute in ruminant feeds, due to its high energy content and good digestibility in ruminant species.

Pectin obtained from dried citrus peels is referred to as citrus pectin. Pectin is a natural, biocompatible, biodegradable and renewable polysaccharide characterized as an emulsifier, gelling agent, glazing agent, stabilizer, and/or thickener.

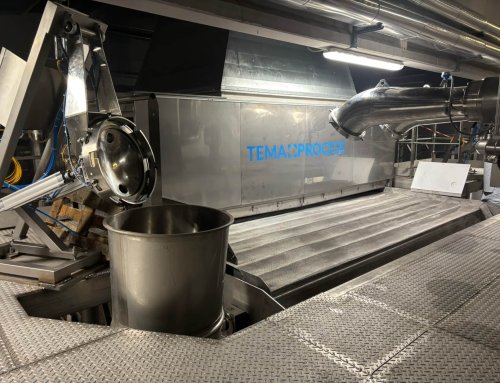

TEMA Process developed a system for drying citrus peel and pulp.

The TEMA Process Fluid bed dryers are widely used to dry orange and lemon peels and offer advantages such as good mixing of solids, high heat and mass transfer rates, ease of operation and maintenance and lower capital costs.