Optimizing Drying Processes for Black Soldier Fly Larvae Using Fluidized Bed Dryers with Plug Flow.

Introduction.

Black Soldier Fly (BSF) larvae have gained significant attention in recent years due to their versatile applications in waste management, animal feed production, and even human consumption. One critical aspect of utilizing BSF larvae is the drying process, which plays a crucial role in preserving their nutritional value and extending their shelf life. In this article, we will explore the benefits of using a fluidized bed dryer with plug flow for drying black soldier fly larvae, emphasizing the optimization of the drying process.

Understanding Black Soldier Fly Larvae Drying

Black Soldier Fly larvae contain valuable nutrients, making them an excellent source of protein and fat for various applications. However, their high moisture content makes them susceptible to spoilage and degradation. Efficient drying processes are essential to maintain the larvae’s nutritional quality and ensure their stability for long-term use.

Fluidized Bed Dryer with Plug Flow

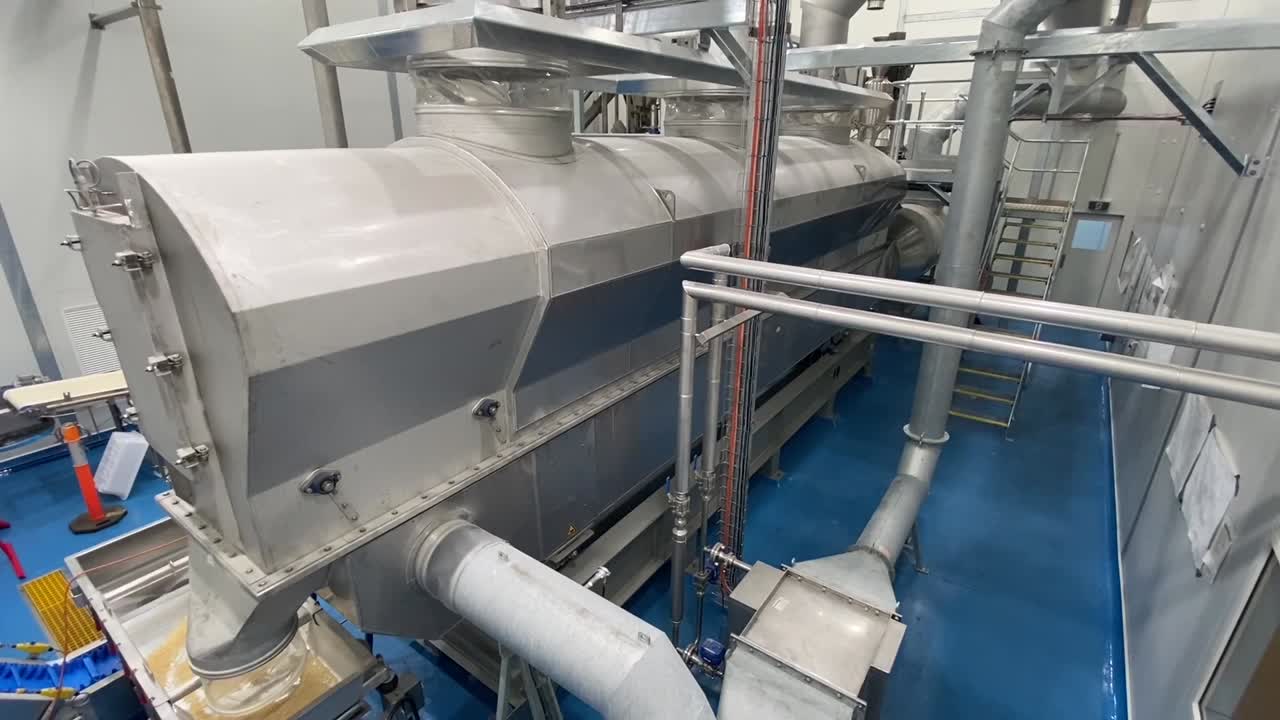

A fluidized bed dryer with plug flow is a specialized drying system designed to enhance the efficiency and uniformity of the drying process. In this system, hot air is introduced into a chamber containing the black soldier fly larvae, creating a fluidized bed of particles. The plug flow design ensures that the larvae move through the dryer in a continuous, streamlined manner, controlled residence time and preventing over and under drying.

Benefits of Fluidized Bed Dryer with Plug Flow for BSF Larvae

– Uniform Drying

The fluidized bed ensures that each individual larvae experiences uniform drying conditions. This uniformity is crucial for maintaining consistent product quality and preventing variations in moisture content.

– Reduced Drying Time

The plug flow design minimizes the time required for larvae to pass through the drying chamber. This not only increases the overall drying efficiency but also helps preserve the larvae’s nutritional content by minimizing exposure to high temperatures.

– Energy Efficiency

Fluidized bed dryers are known for their energy efficiency. By utilizing hot air in a controlled manner, these dryers can achieve the desired moisture reduction with minimal energy consumption, contributing to sustainable and cost-effective drying processes.

– Preservation of Nutritional Value

The controlled and efficient drying process helps retain the essential nutrients in black soldier fly larvae, ensuring that the final product maintains its nutritional value and meets quality standards.

– Hygienic Processing

The continuous flow of larvae through the fluidized bed minimizes the risk of contamination and ensures a hygienic drying environment. This is particularly important for applications such as animal feed and human consumption where product safety is paramount.