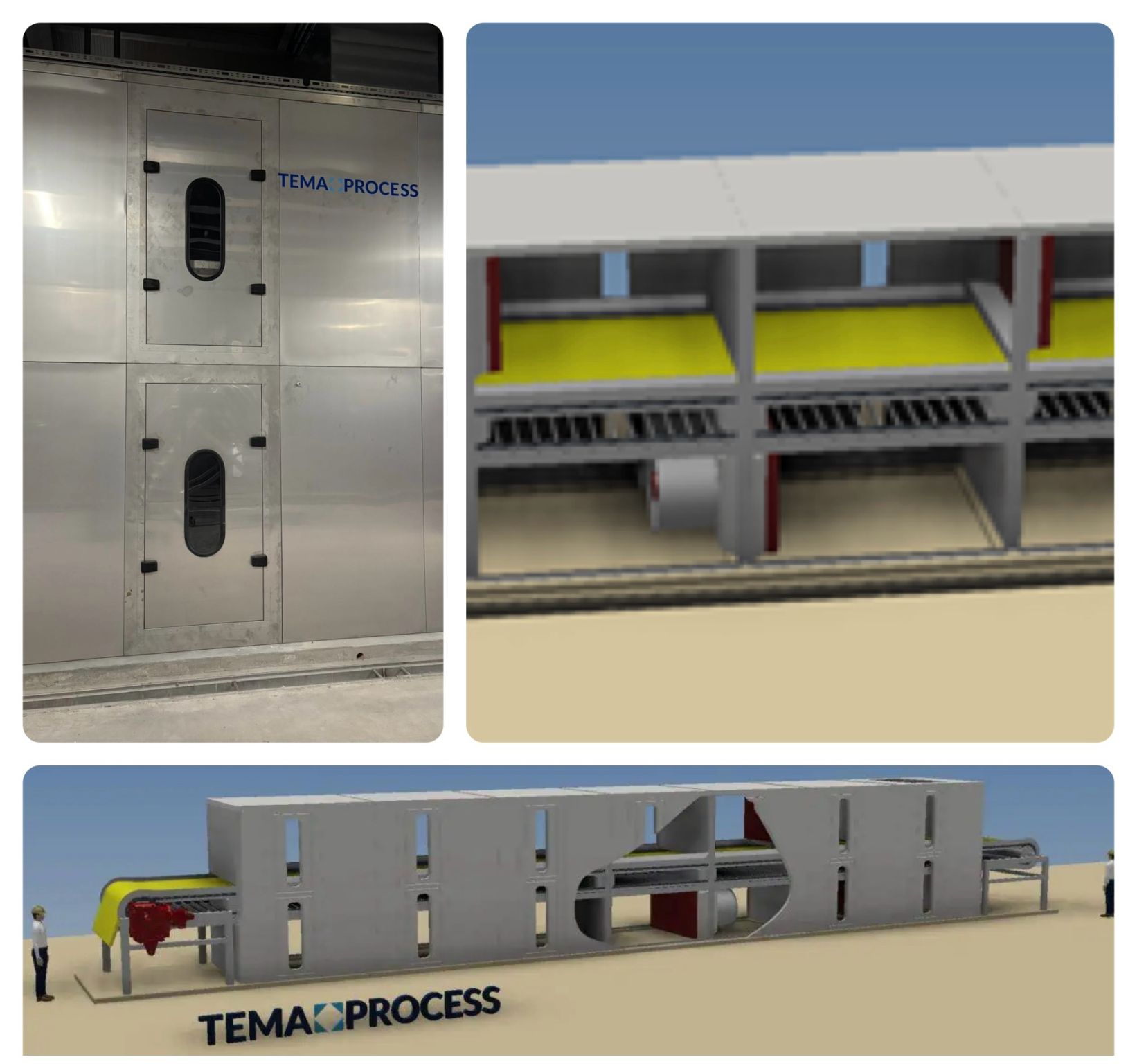

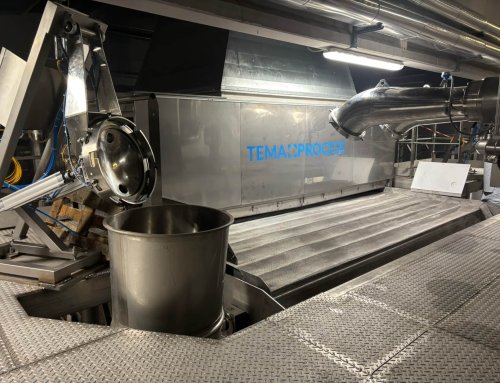

The gelatin belt dryer with a dehumidifier by TEMA Process is regarded as one of the best systems for gelatin drying due to its advanced technology, precision control, and reliable performance. Here’s why the TEMA Process belt dryer stands out:

1. Advanced Dehumidification Technology

• TEMA Process integrates highly efficient dehumidification systems into their belt dryers. By continuously removing moisture from the drying air, the system ensures a low-humidity environment that accelerates drying while maintaining product integrity.

• The combination of controlled temperature and dehumidified air prevents overheating or damage to the gelatin structure.

2. Optimized Drying Efficiency

• TEMA Process belt dryers are designed for high efficiency and uniform drying. The dehumidifier significantly reduces the moisture load, which improves the overall drying process and reduces drying time.

• This optimized airflow and moisture control ensure a faster throughput without compromising product quality.

3. Precision Control for Product Quality

• TEMA Process systems allow for precise control over temperature, airflow, and humidity levels, which is critical for sensitive products like gelatin.

• Gelatin requires gentle drying conditions, and TEMA Process technology ensures the product remains free from defects like cracking, melting, or brittleness.

4. Energy Efficiency and Sustainability

• TEMA Process belt dryers are known for their energy-efficient design. By using advanced dehumidification systems, the dryers recycle and condition the drying air, reducing energy consumption.

• This leads to significant cost savings and makes the system more environmentally friendly compared to traditional drying technologies.

5. Scalable and Automated Solutions

• TEMA Process belt dryers are highly scalable, making them suitable for both small and large-scale gelatin production.

• The systems are fully automated with user-friendly controls, ensuring seamless operation, minimal labor requirements, and consistent results.

6. Robust and Reliable Design

• TEMA Process dryers are engineered for durability and reliability, ensuring long-term performance even under demanding production conditions.

• Their robust construction minimizes downtime, reduces maintenance costs, and enhances operational efficiency.

7. Hygienic and Contamination-Free Drying

• The closed and controlled drying system by TEMA Process minimizes contamination risks. This is particularly important for gelatin production, where cleanliness and product safety are paramount.

• The hygienic design complies with industry standards, ensuring a safe and clean end product.