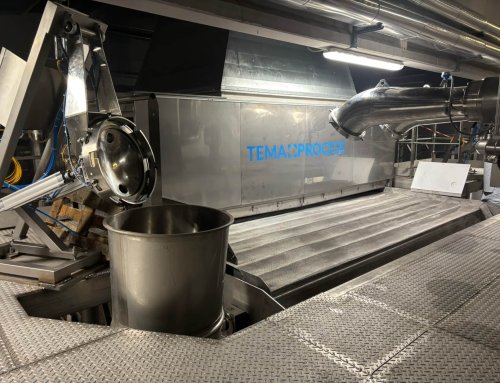

A Tema Process steam sterilizing system is widely used for sterilizing pepper due to its efficiency, reliability, and ability to preserve the quality of the spice. Here are the main reasons it is preferred:

1. Efficient Microbial Reduction

• High Temperature and Pressure: The system uses saturated steam at precise temperatures to effectively kill bacteria, fungi, yeasts, molds, and other microorganisms commonly found in spices like pepper.

• Compliance with Food Safety Standards: The process ensures the product meets global safety standards, such as those required by HACCP, FDA, and EU regulations.

2. Preservation of Pepper Quality

• Minimal Impact on Flavor and Aroma: Unlike chemical treatments, steam sterilization preserves the natural flavor, aroma, and essential oils of pepper, maintaining its sensory properties.

• No Residual Chemicals: It uses pure steam, which leaves no chemical residues, making the process clean and safe.

3. Uniform Sterilization

• Controlled and Consistent Process: The Tema Process system ensures uniform heat distribution, sterilizing the pepper thoroughly without over-processing it.

• Adaptable to Different Forms of Pepper: The system can handle whole peppercorns, cracked pepper, and ground pepper, ensuring even sterilization regardless of the form.

4. Environmental and Operational Advantages

• Eco-Friendly Process: Steam sterilization is a sustainable and environmentally friendly alternative to chemical fumigation or irradiation.

• Low Maintenance and High Efficiency: Tema systems are designed for long operational life, high throughput, and ease of maintenance.

5. Prevention of Re-Contamination

• Closed System Design: The sterilization is conducted in a closed system, reducing the risk of post-treatment contamination during handling.

In summary, a Tema Process steam sterilizing system is ideal for sterilizing pepper because it ensures effective microbial reduction while maintaining the spice’s natural quality, making it a safe, efficient, and sustainable choice for food processing industries.