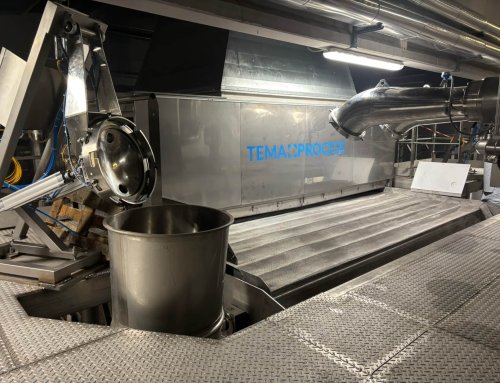

Erection and commissioning of a Tema Process sand dryer with heat recovery system. Sand is often dried for several practical reasons across different industries and applications.

1. Construction

• Consistency: Dry sand is easier to measure and mix accurately with cement and other materials. Moist sand can cause inconsistencies in ratios.

• Storage: Wet sand can clump together, making it difficult to transport and use effectively.

• Strength: Removing moisture from sand prevents unwanted water content in certain applications like concrete or mortar preparation.

2. Industrial Use

• Manufacturing: Dry sand is used in processes like sandblasting, glass production, and metal casting, where moisture could interfere with machinery or final products.

• Filtration: In water filtration systems, dry sand is preferred because it prevents bacterial growth and clogging.

3. Sandblasting and Surface Treatment

• Efficiency: Dry sand flows more consistently and efficiently through sandblasting equipment. Wet sand could damage tools or clog the nozzles.

4. Landscaping and Playgrounds

• Safety: Wet sand can harbor mold, bacteria, or fungi, making it unsuitable for play areas or landscaping.

5. Storage and Transport

• Weight: Dry sand is lighter than wet sand, reducing transportation costs.

• Preventing Freezing: In cold climates, wet sand can freeze and become unusable.

Drying sand ensures it meets specific requirements for quality, usability, and safety across these various applications.

#sand#drier#dryer#temaprocess