In the production of green gas via anaerobic digestion (AD) of wet biomass, sustainably managing the resulting digestate remains a key challenge. A highly effective solution combines a back-mix system with a fluidized bed dryer, as developed by TEMA Process.

Back-Mix System: Pre-Conditioning with Ploughshare Mixing

Wet digestate or concentrate (with 8–30% dry matter) is continuously mixed with dried digestate using a ploughshare mixer. This high-intensity mixing process granulates the material and blends the moist feed with recycled dried product. The result is a stable, homogeneous mixture with approximately 70–80% dry matter—ideal for thermal drying.

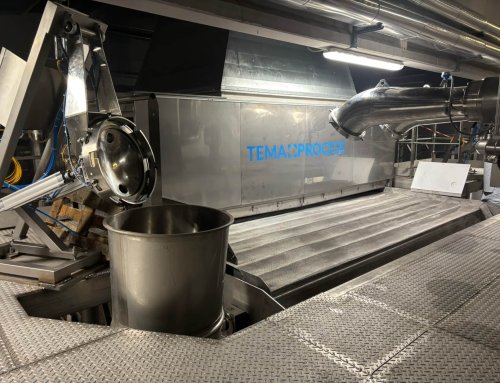

Fluidized Bed Drying by TEMA Process

Using a controlled flow of hot air, the digestate is fluidized to ensure rapid and uniform moisture removal—down to approximately 10–15% dry matter. TEMA Process systems are recognized for their high efficiency, process stability, and the ability to integrate with waste heat sources such as CHP systems or biogas upgrading units.

Circular and Sustainable Approach

The dried digestate becomes a valuable end-product, such as fertilizer or biofuel, while also maximizing heat recovery within the plant. This approach supports circular economy principles and significantly reduces emissions associated with digestate storage and transport.

TEMA Process provides turnkey drying solutions that enhance efficiency, reliability, and sustainability in biogas operations.