The sea salt washing and drying process is essential to produce clean, high-quality salt suitable for consumption and industrial use. Here’s a general overview of the process:

1. Harvesting the Sea Salt

• Sea salt is typically harvested from salt pans or evaporation ponds where seawater has been left to evaporate, leaving behind crystallized salt.

• The harvested salt often contains impurities such as sand, clay, and other minerals.

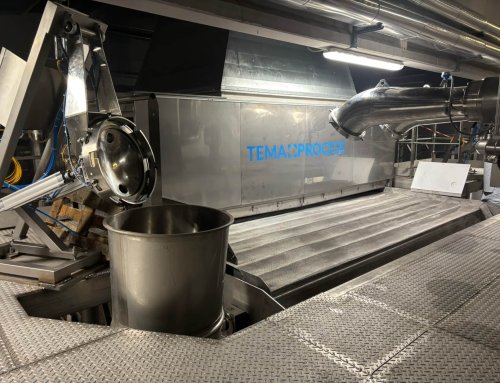

2. Washing Process

• Initial Rinsing: The raw salt is washed with a brine solution (saturated saltwater) rather than freshwater to prevent salt loss through dissolution.

• Multiple Wash Cycles: The salt undergoes multiple washing cycles to remove dirt, magnesium, calcium compounds, and other impurities.

• Centrifugal Separation: The washed salt may be passed through a centrifuge to remove excess water quickly.

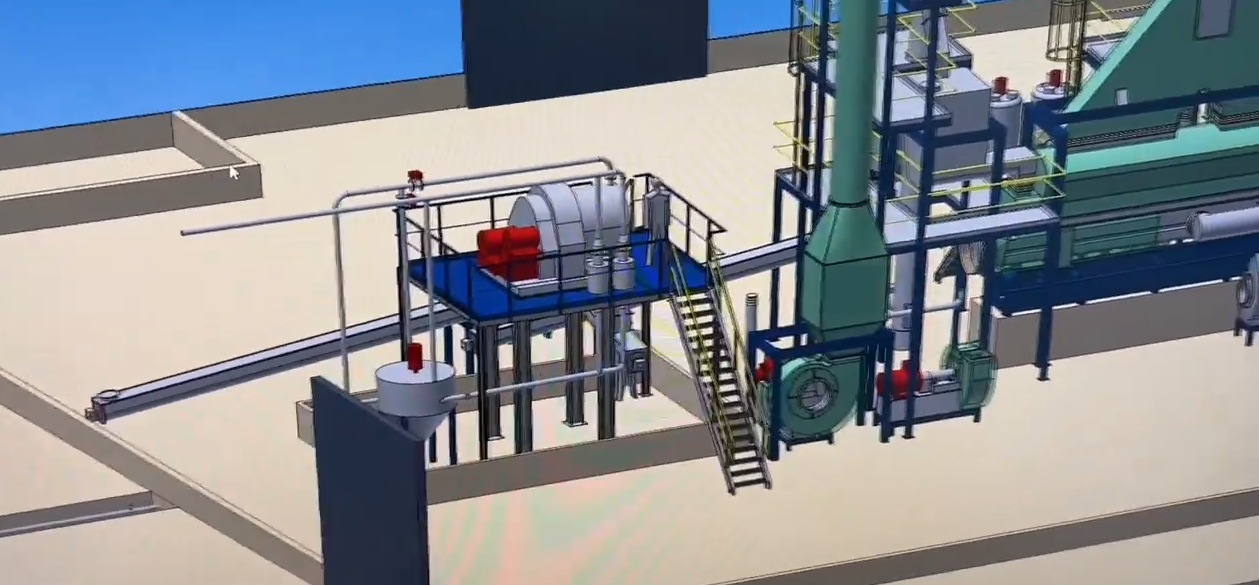

3. Drying Process

• Draining: After washing, the salt is allowed to drain excess water.

• Fluidized Bed Drying: The salt is then dried using a fluidized bed dryer, where hot air is passed through the salt particles, keeping them suspended for even and efficient drying.

• Cooling: After drying, the salt is cooled to prevent clumping and ensure it remains free-flowing.

4. Final Processing and Packaging

• The dried salt may undergo further refining, grinding, or sieving to achieve the desired grain size.

• Anti-caking agents may be added if necessary.

• The processed salt is then packaged for commercial sale.

This process ensures that the sea salt is clean, dry, and suitable for culinary, cosmetic, or industrial applications.

# seasalt#nacl#dryer