TEMA Process: Your Strategic Partner for Gelatin Drying and Turn-Key EPC Solutions

In the gelatin industry, drying is a critical step that directly impacts product quality, consistency, and operating costs. Gelatin and collagen-based products are widely used across food, pharmaceutical, and cosmetics applications—making reliable, controlled drying essential.

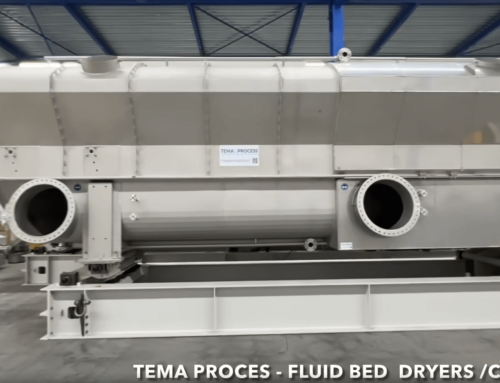

At TEMA Process, we specialize in gelatin drying and act as a trusted EPC contractor for turn-key gelatin drying installations. We combine deep process expertise with in-house engineering and manufacturing to deliver drying solutions that perform—today and long into the future.

End-to-End Delivery — From Concept to Operational Line

We provide complete drying solutions you can rely on, including:

• Process design and detailed engineering

• In-house equipment manufacturing

• On-site installation and commissioning

• Operator training and knowledge transfer

• Long-term service and maintenance support

Whether you’re investing in a new drying installation or optimizing an existing line, we deliver a practical, performance-driven approach.

How We Support the Gelatin Industry

Gelatin is sensitive to temperature and humidity, so stable air conditions and precise control are key. Our solutions are designed specifically to meet these requirements.

1. Belt Dryers for High-Quality Gelatin

Our belt dryers are engineered for controlled, consistent drying and can be integrated with hygienic air dehumidification and multi-zone, temperature-controlled drying for reliable product results.

2. Spray Dryers for Collagen Peptides

Spray drying enables efficient conversion of liquid feed into stable powders—supporting consistent product quality and scalable production for collagen peptide applications.

3. Dehumidification Equipment

Humidity control is essential for a stable drying process. Our dehumidification solutions help optimize air conditions, protect product quality, and support energy-efficient operation.

Projects We Deliver

Continuous Process Improvement

• Higher product consistency

• Increased throughput and capacity

• Lower energy cost per kilogram of dry product

EPC Contracting for Gelatin Drying Installations

• As an EPC (Engineering, Procurement & Construction) contractor, we take responsibility for the design, procurement, and construction of your gelatin drying installation—with one clear point of contact and a turn-key delivery approach.

Advanced PLC Control & Data Analytics

• With modern PLC control, monitoring, and data analysis, we help create transparent processes with real-time insights—supporting optimization and faster troubleshooting.

Corrective & Preventive Maintenance

• After start-up, we support long-term performance with maintenance services that reduce downtime and protect equipment availability.

Why TEMA Process?

Our combination of process knowledge, engineering depth, in-house manufacturing, and automation expertise makes TEMA Process a strong long-term partner for the gelatin industry—focused on results in quality, capacity, and energy efficiency.

Let’s Talk

Looking to improve drying performance, stabilize quality, or reduce energy cost per kg? Let’s explore how TEMA Process can support your gelatin drying installation.