For lithium hydroxide monohydrate, it is essential to dry it at a temperature and humidity that avoids removing the water of crystallization, which would turn it into anhydrous LiOH or cause it to react with carbon dioxide. To achieve dry lithium hydroxide monohydrate, the wet salt needs to be dried, keeping the monohydrate stage, and without removing crystalline water. The drying system uses a CO2 -free fluidization gas in a closed loop with adjusted humidity to stay within the stable area where no monohydrate water is removed.

Drying gentle LiOH with a Tema fluid bed dryer involves using hot air to fluidize the wet lithium hydroxide monohydrate crystals, which are then dried efficiently as they are suspended in the air.

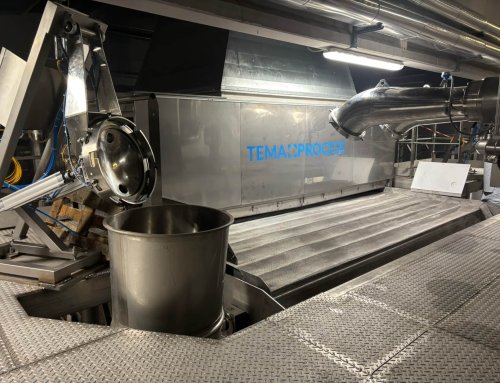

A gentle drying fluid bed with shaking, a system by Tema Process, uses a low-frequency, high-amplitude shaking motion to enhance drying efficiency while minimizing product damage. This combination of gentle shaking and fluidization ensures a controlled, step-by-step product transport and even drying.

The shaking mechanism creates a “plug flow” which leads to first-in, first-out drying and a more uniform residence time. Drying and cooling of monohydrate can be combined in a single fluid bed.

This process is a standard and reliable method in the battery chemical industry for producing battery-grade lithium hydroxide, often after the product has been separated from the liquid solution.

The dryer can handle high production capacities and is adaptable to different scales and applications, and features like Clean-In-Place (CIP) systems are available for and automated cleaning.