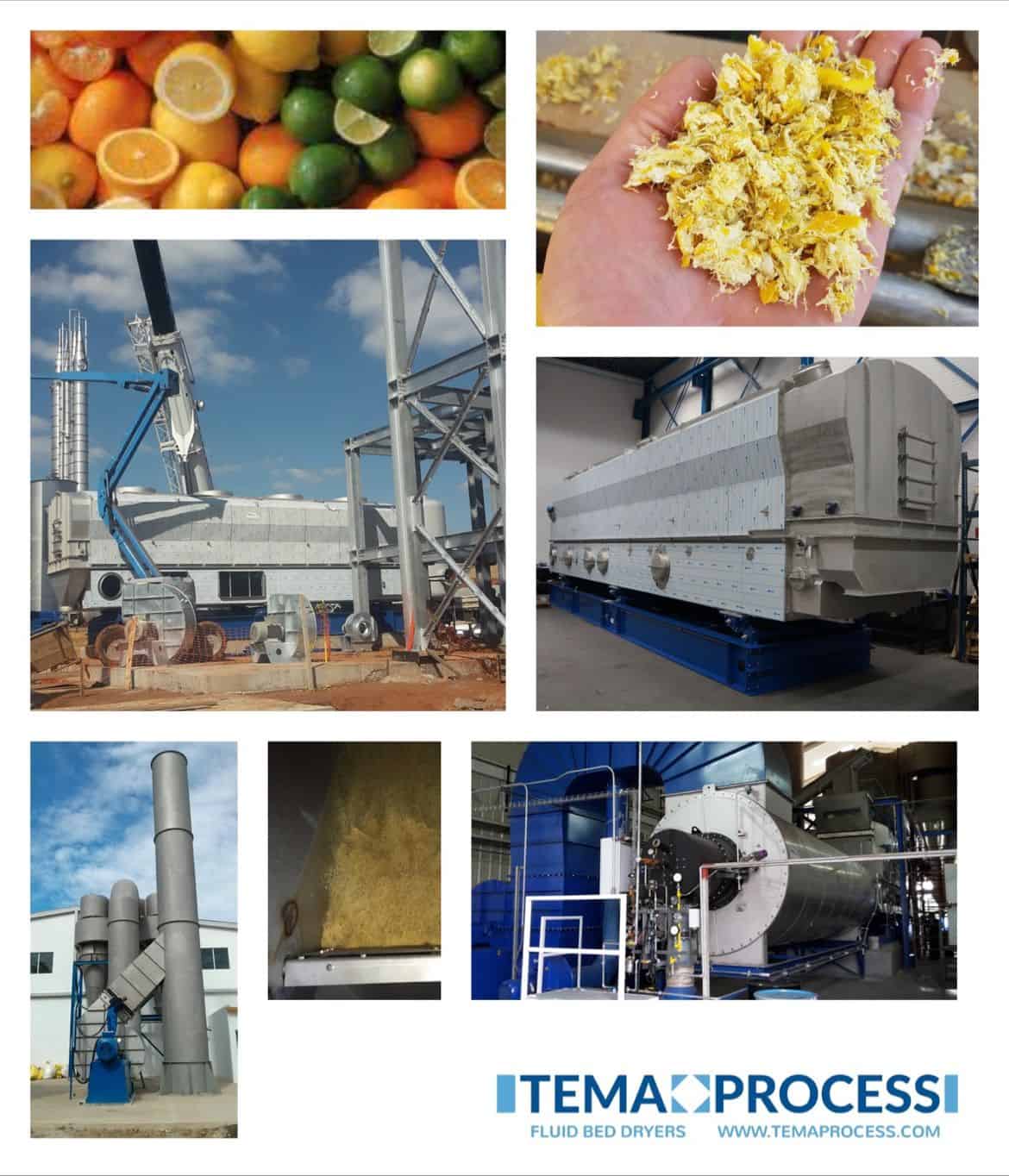

Drying citrus peel on an industrial scale is a common process used to preserve the peels for various applications in the food, beverage, pharmaceutical, and cosmetic industries.

The drying process removes the moisture from the peels, extending their shelf life and making them easier to handle and transport.

Drying citrus peels concentrates the natural flavour and aroma compounds present in the peels.

This concentrated flavour is valuable for use in various culinary and beverage applications, such as flavouring teas, infusions, and seasonings.

Waste reduction and value addition

Citrus peels are often considered by-products of the fruit juice industry. By drying and processing the peels, the waste is minimized, and additional value is derived from what would otherwise be discarded.

Convenience and storage

Dried citrus peels are lightweight, easy to store, and transport, compared to fresh peels, which are bulky and have a limited shelf life.

In summary, drying citrus peel on an industrial scale offers numerous benefits, including prolonged shelf life, concentrated flavour and aroma, waste reduction, and enhanced convenience for storage and transportation.

These dried citrus peels find applications in various industries and consumer products. Pectin is a complex carbohydrate (polysaccharide) found in the cell walls of various fruits, including citrus fruits such as oranges, lemons, and limes.

Citrus peels are a rich source of pectin, making them a valuable raw material for pectin extraction. Pectin is widely used in the food industry as a gelling agent, stabilizer, and thickener in a variety of products.