Drying sand

Typically, sand is mined, washed and screened and stored in piles with various grades. The sand needs to be dried to the required moisture content before it can be sold or further processed. Silica sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules. Silica sand is the primary component of all types of standard and specialty glass. But it is also used in a lot of industries/processes, like : metal casting/production, chemical production, construction, paint and coating, ceramics & refractories, filtration and water production, oil and gas recovery etc.

Drying of sand, aggregates, limestone, clay, talc, kaolin, feldspar, potash, phosphates, salt, slag, frac sand, gravel etc, it is all about maximize return on investment by reducing energy expenses.

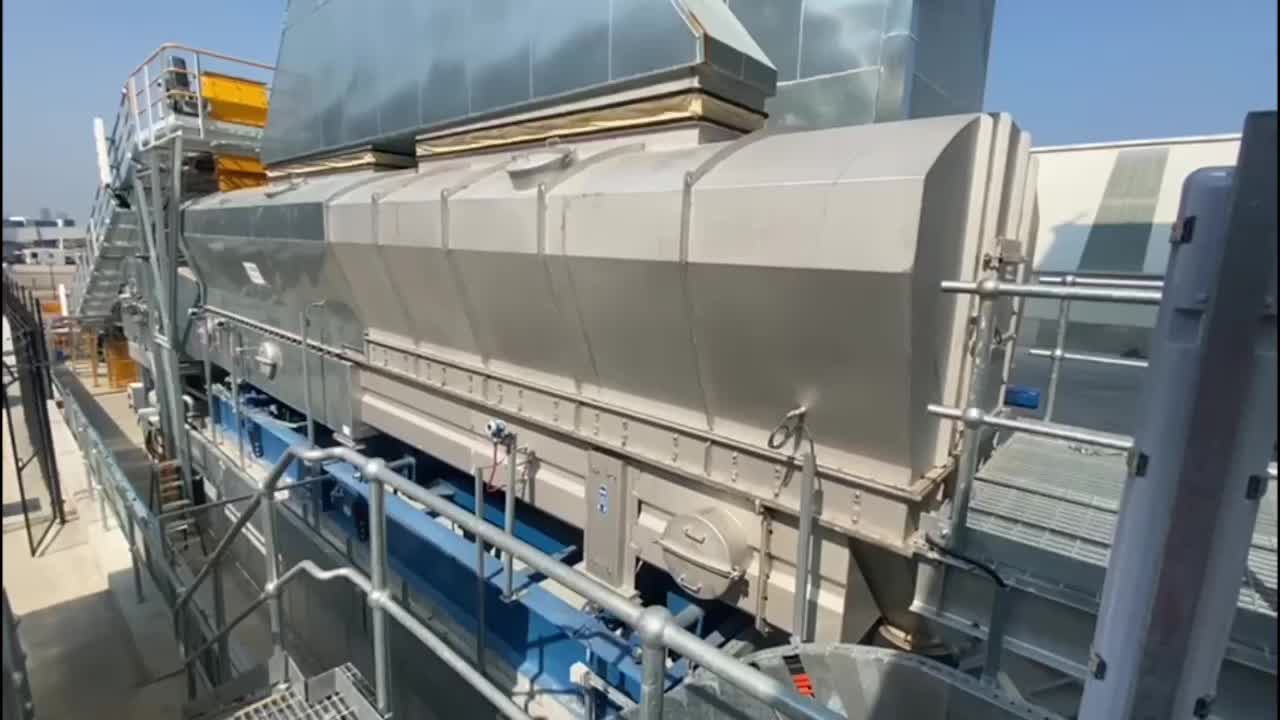

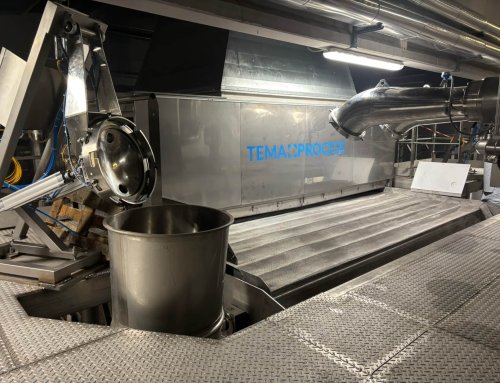

Shaking fluid bed dryers are frequently used for the drying of raw natural minerals or pre-processed minerals. The unique TEMA Process shaking drive mechanism allows for a uniform drying result for a large spread in particle size distribution ( 110 microns – 10 mm) , without disruptions of the fluid bed. This shaking design is suitable for capacities up to 100 t/h in a single unit.