In virtually every facility handling bulk solids, an industrial drying step plays a critical role—whether in preparing feedstock, finishing a product, or meeting tight quality standards. Two of the most commonly used technologies in industrial drying are rotary dryers and fluid bed dryers. While their applications sometimes overlap, the way each system operates leads to important distinctions in performance, efficiency, and suitability.

How Rotary Dryers Work

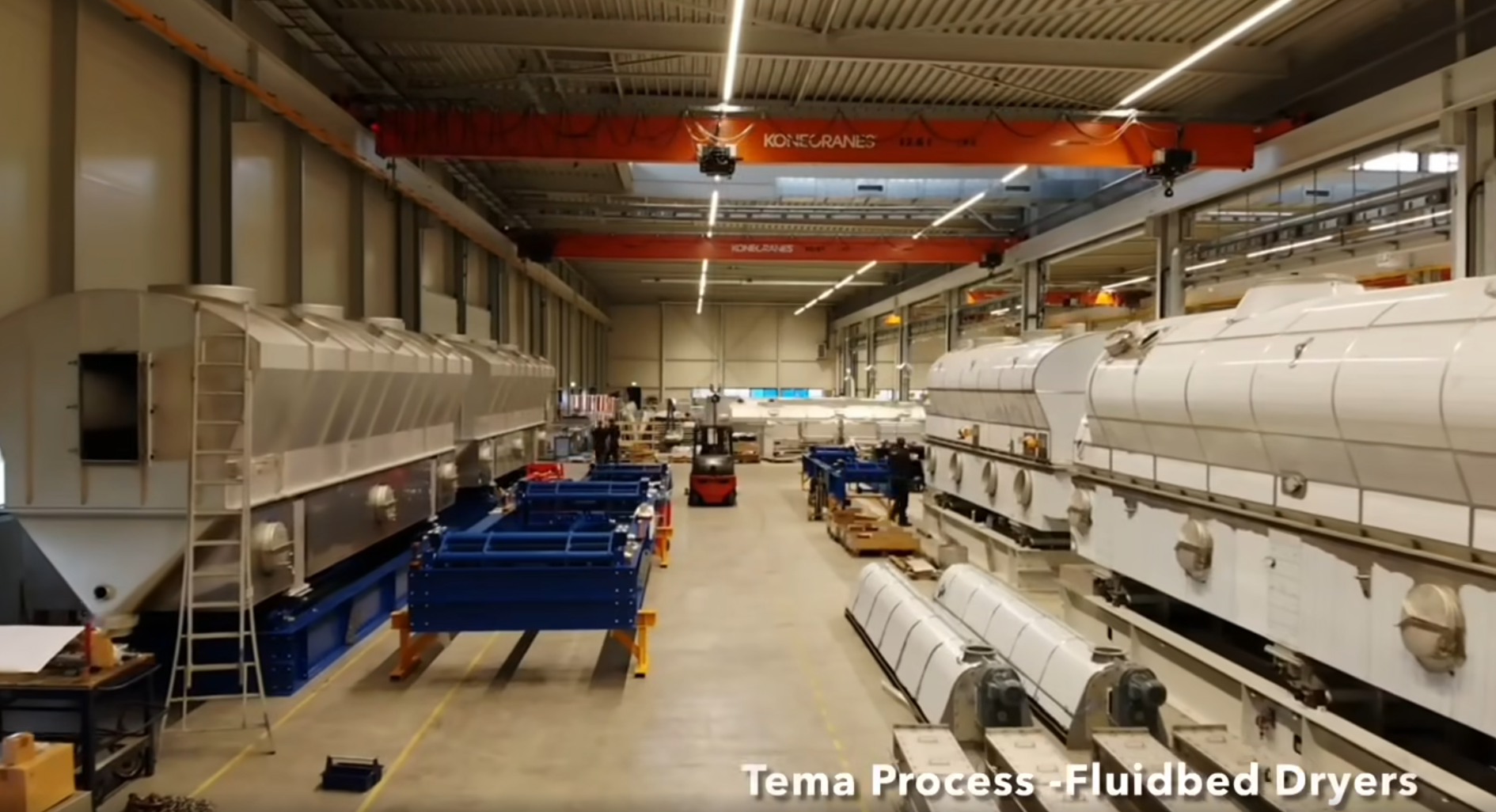

A rotary dryer consists of a slightly inclined, horizontally rotating drum. Material is fed into one end and gradually moves to the other end, aided by gravity and the drum’s motion. Inside the drum, flights (or lifters) pick up and drop the material through a hot gas stream. This creates a cascading curtain of material, optimizing heat transfer between the process gas and the product.

How Fluid Bed Dryers Work

Fluid bed dryers operate on a different principle: air is pushed through a perforated plate from the bottom up, fluidizing the bulk solids. In this suspended state, each particle is surrounded by hot air, resulting in very efficient thermal performance and gentler material handling compared to rotary dryers.

Energy Consumption and Efficiency

Fluidized bed dryers are generally more energy-efficient than rotary dryers. This is largely due to their excellent heat transfer performance: when bulk solids are fluidized, each particle is suspended and surrounded by hot air, allowing for rapid, uniform drying. This setup minimizes heat loss and maximizes thermal efficiency, making fluidized bed systems more energy-friendly overall.

However, this efficiency comes with some conditions. Fluid bed dryers require a consistent feed of material with relatively uniform particle size and moisture content. They also depend on maintaining a specific airflow to achieve fluidization, which means they may not be as flexible or efficient during reduced-capacity operation.

By contrast, rotary dryers are better suited for handling materials with larger particle sizes or higher bulk densities, where fluidization would require an uneconomical amount of energy. While rotary dryers typically operate at higher inlet temperatures and may not reach the same thermal efficiency as fluid bed dryers, they are more tolerant of feed variation and can still offer some energy savings when run below full capacity.

Capacity and Space

Rotary dryers handle larger volumes and are ideal for high-capacity operations. However, they take up more space. Fluid bed dryers are compact and well-suited for smaller facilities with moderate throughput needs.

In summary, fluidized bed dryers are more energy-friendly in stable, well-controlled environments with light, uniform materials, whereas rotary dryers are more robust and adaptable in variable or heavy-duty operations.