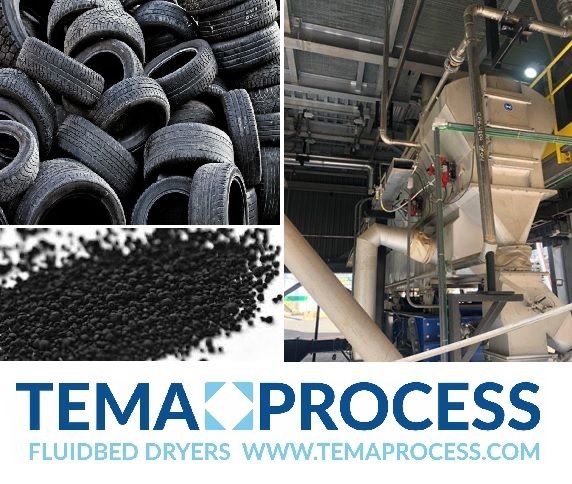

As recovered carbon black (rCB) continues to grow in relevance across industries focused on sustainability and circular economy goals, the need for reliable, high-quality drying solutions becomes increasingly important. Drying rCB efficiently is critical not only for preserving its performance characteristics but also for ensuring safety, handling, and downstream usability in applications like rubber, plastics, and coatings.

Fluid bed dryers have emerged as the technology of choice for this purpose. Their ability to deliver fast, uniform drying ensures consistent moisture removal, even when dealing with variable feedstocks and particle sizes. The fluidized process offers gentle handling, which helps maintain the integrity and surface area of the rCB—key factors for its reinforcing properties and dispersion in final products.

Precise temperature control allows operators to avoid thermal degradation or combustion, which is particularly important given the presence of volatile residues in some rCB materials. These dryers can also be operated with inert gases such as nitrogen, adding another layer of safety. Enclosed systems and built-in filtration minimize dust emissions and explosion risk, ensuring compliance with workplace safety and environmental regulations.

Beyond performance and safety, fluid bed dryers are also highly energy-efficient. They can integrate heat recovery systems and operate with lower energy consumption compared to other drying technologies.

For manufacturers working with recovered carbon black, choosing fluid bed drying isn’t just a technical decision—it’s a smart investment in quality, safety, and sustainable operations.