Drying Black Soldier Fly Larvae Using a TEMA PROCESS Fluid Bed Dryer

The Black Soldier Fly Larvae (BSFL) industry is rapidly expanding as demand grows for sustainable protein and fat sources for animal feed, pet food, and aquaculture. A critical step in BSFL processing is efficient and controlled drying, which ensures product stability, hygiene, and nutrient preservation. TEMA PROCESS Fluid Bed Dryers offer a proven and robust solution for this application.

Principle of Fluid Bed Drying

A TEMA PROCESS continuous fluid bed dryer conveys a continuous flow of wet Black Soldier Fly Larvae across a perforated air distribution plate. Hot drying air is introduced into the system through a wind box located beneath the plate. As the air passes through the perforations, it lifts and suspends the larvae, causing them to behave like a fluid.

This fluidization significantly enhances heat and mass transfer between the larvae and the drying air, allowing moisture to be removed efficiently and uniformly. Compared to static or batch drying systems, fluid bed drying provides superior control over drying kinetics and final product moisture.

Air Handling and Product Retention

During the drying process, the air absorbs moisture evaporated from the larvae and exits the fluid bed through a suction hood. This hood is deliberately widened to reduce air velocity, minimizing the risk of particle entrainment and ensuring that larger larvae fragments remain in the dryer. This design contributes to high product yield and clean operation.

Controlled Conveying and Plug Flow

Product transport through the dryer is achieved using a low-frequency, high-amplitude shaking mechanism. This shaking motion improves fluidization behavior and ensures controlled conveying of the larvae through the dryer.

A key advantage of the TEMA PROCESS design is the creation of plug-flow conditions. This enables first-in, first-out (FIFO) processing, ensuring that all larvae experience a similar residence time and thermal exposure. The result is a consistent, evenly dried product with minimal risk of over- or under-drying.

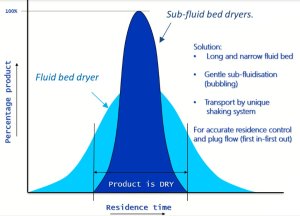

Sub-Fluid Bed Drying for Extended Residence Times

In some BSFL applications—such as whole larvae drying or gentle low-temperature processing—longer residence times are required. For these cases, TEMA PROCESS offers sub-fluid bed dryers.

In conventional fluid bed dryers, product layer thickness is typically limited to 10–15 cm, as thicker layers lead to excessive axial mixing and a broad residence time distribution. Sub-fluid bed drying overcomes this limitation by operating with significantly thicker product layers, up to 60 cm.

By carefully limiting the airflow to the minimum required for moisture removal, mixing within the product bed is kept to a minimum. This allows residence times of up to two hours without substantial axial mixing. Sub-fluid bed dryers are generally designed with a narrow and elongated layout, further supporting stable plug-flow behavior.

Advantages for BSFL Processing

Using a TEMA PROCESS Fluid Bed Dryer for Black Soldier Fly Larvae offers several key benefits:

- Uniform and efficient moisture removal

- Excellent control over residence time and product temperature

- Gentle handling, preserving protein and fat quality

- Scalable continuous operation suitable for industrial production

- Hygienic and energy-efficient dryer design

Conclusion

As the BSFL industry continues to industrialize, reliable and well-controlled drying technology becomes essential. TEMA PROCESS Fluid Bed Dryers, including sub-fluid bed configurations, provide a flexible and proven solution for drying Black Soldier Fly Larvae efficiently, consistently, and at industrial scale—supporting high product quality and sustainable protein production.