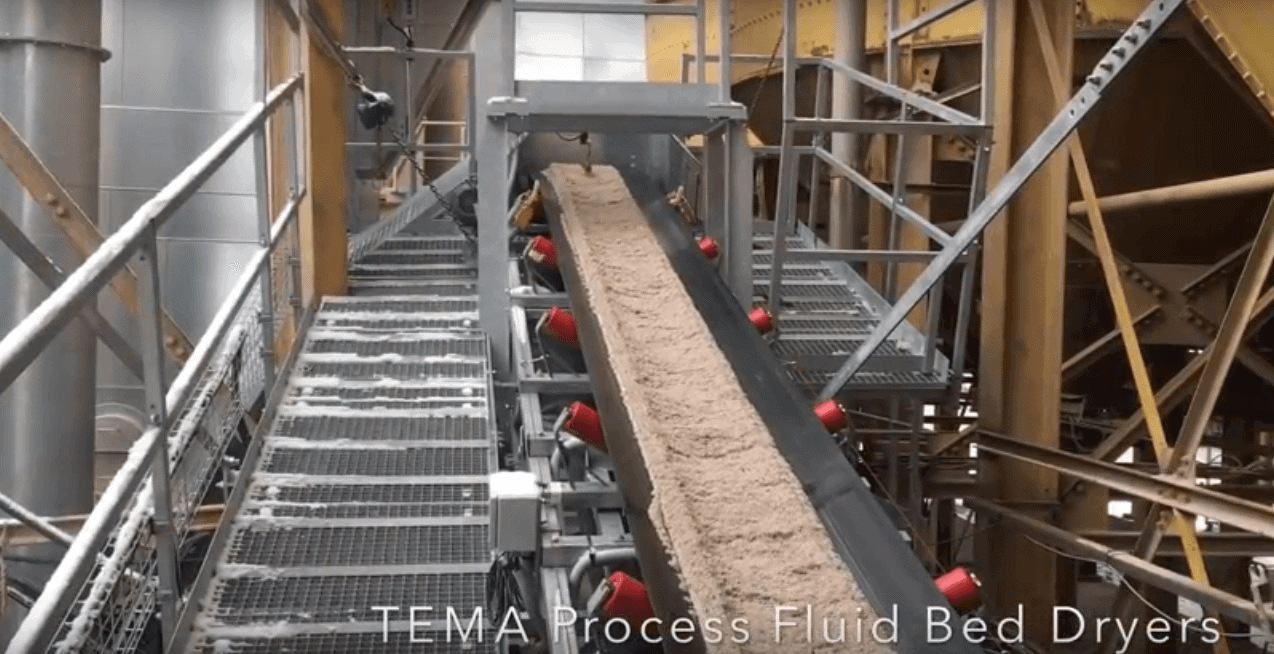

High Temperature, low energy dryer

High temperature drying at up to 600°C: This results in greater evaporation per square metre of bed without an increase in air volume, reduces the power consumption per tonne of sand dried and improves fuel efficiency. The TEMA Fluid Bed dryer is split into two sections, the first of which operates at a high temperature (up to 600°C).

In the first stage of drying, free (surface) moisture is removed from the product and all available energy supplied as heat in the drying air is used for evaporation. A volume of air, saturated with is taken from this loop and passed through an air/air heat exchanger. With this heat exchanger, the latent heat from the exhaust air is used for heating the air for the second section. This flow of air is then used as the drying agent in the second stage of the dryer, where the product is heated up to a controlled temperature of not more than 50 °C. Due to the evaporative cooling effect, in the case of sand and most other granular minerals cooling is, therefore, not necessary. The exhaust air from the second stage is dry and can, therefore, be recycled to the burner inlet, reheated and used again, which result in another energy saving.