Shipping dryers [video]

Carefully planned and efficient logistics management is essential to the success of a manufacturing/engineering company. In order to be successful in a competitive global economy, it’s necessary to find the most cost-effective and efficient way to get our equipment or from point A to point B. The transportation of industrial equipment or machinery often involves out of gauge freight that doesn’t fit into regular shipping [...]

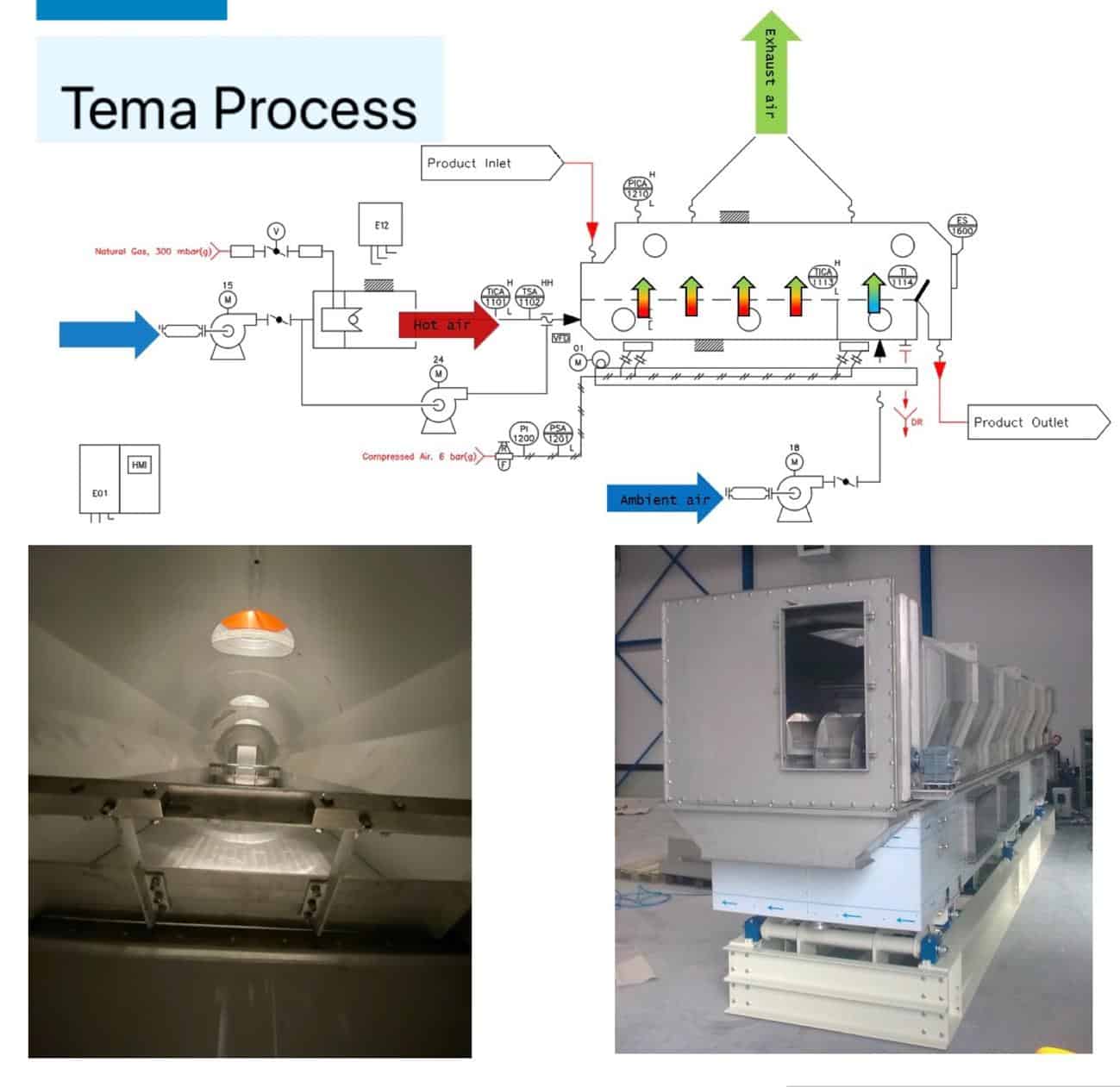

Increasing production capacity [video]

Increasing production capacity ! We have completed the expansion of our production/assembly facility in Wapenveld, the Netherlands.

Fluid bed dryers for spray drying [video]

Spray drying is a method of producing a dry powder from a liquid by rapidly drying with a hot gas. This is the preferred method of drying of many thermally sensitive food products, like milk powder, proteins, vitamins, nutraceutical etc, A fine powder is produced with a spray dryer but it can have a poor product flow. Instead of drying the liquid in one stage, [...]

Weir for controlling the bed height / residence time in Fluid Bed Dryers

Weir for controlling the bed height/ residence time in Fluid Bed Dryers: In an efficiently fluidized bed, the solid material like granules/powders or pellets, are fluidized by an upflow gas. The wet solids are lifted from the bottom and causes the solids to behave as a fluid. The air velocity is adjusted to keep the moving layer of material fluidized. At the end of the [...]

Meatless has ordered a new high volume fluid-bed drying system for expanding the capacity of its dehydrated production

Meatless has ordered a new high volume fluid-bed drying system for expanding the capacity of its dehydrated production. Building time is expected to be six months and we think that the line will be operational in August 2020. Tema Process will build the machine, which will not only triple our capacity but also opens the opportunity to produce a portfolio of innovative new textured products [...]

Tema Process fluid bed drying systems are the preferred solution in the food, feed and pharma industry

Whenever a hygienic or sanitary design has high priority, the Tema Process fluid bed drying systems are the preferred solution in the food, feed and pharma industry. Together with a gentle and uniform drying result, fluid bed systems are capable to preserve a high quality of the handled ingredients.

Reducing energy expenses & operating cost

Reducing energy expenses ! Tema Process continuous innovate to reduce operating costs and improve process performance. The Tema Process fluid bed drying system recovers the energy from the exhaust air and uses this to pre-heat the air for the drying process. Our fluid beds can be designed to use controlled evaporative cooling to reduce energy consumption. We can recover the heat from the cooled product [...]

One Solution – SIEBTECHNIK TEMA and TEMA PROCESS are part of globally operating group

One Solution - Worldwide. are aSIEBTECHNIK TEMA and TEMA PROCESS part of a globally operating group of companies with around 3,500 employees in more than 50 countries with a clear focus on the solid-liquid separation as well as processing of bulk solids in the mineral, chemical, food and Waste & Recycling industries. In many cases the SIEBTECHNIK TEMA centrifuge is placed in line with the [...]

Transport of fluid bed dryers

Transport of Fluid Bed Dryers/Coolers: In order to be successful in a competitive global economy, it’s necessary to find the most cost-effective and efficient way to get our fluid bed dryers, parts and other equipment from point A to point B. This can involve equipment transportation, warehousing and more. We offer all kinds of service within road freight, sea freight or air freight. We are [...]

Erection and commissioning of a sand dryer

Erection and commissioning of a sand dryer: We offer assistance with erection and commissioning of the fluid bed dryer equipment. Also we can give operator training, technical/maintenance training, machine process training and safety training. Our fluidized bed dryers are constructed from the highest quality materials and are guaranteed to provide a lasting return on the investment. The mineral dryers operate at temperatures up to 600° [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety

![Increasing production capacity [video]](https://temaprocess.com/wp-content/uploads/2020/06/Increasing-production-capacity-video.png)