Reducing energy expenses & operating cost

Reducing energy expenses ! Tema Process continuous innovate to reduce operating costs and improve process performance. The Tema Process fluid bed drying system recovers the energy from the exhaust air and uses this to pre-heat the air for the drying process. Our fluid beds can be designed to use controlled evaporative cooling to reduce energy consumption. We can recover the heat from the cooled product [...]

One Solution – SIEBTECHNIK TEMA and TEMA PROCESS are part of globally operating group

One Solution - Worldwide. are aSIEBTECHNIK TEMA and TEMA PROCESS part of a globally operating group of companies with around 3,500 employees in more than 50 countries with a clear focus on the solid-liquid separation as well as processing of bulk solids in the mineral, chemical, food and Waste & Recycling industries. In many cases the SIEBTECHNIK TEMA centrifuge is placed in line with the [...]

Transport of fluid bed dryers

Transport of Fluid Bed Dryers/Coolers: In order to be successful in a competitive global economy, it’s necessary to find the most cost-effective and efficient way to get our fluid bed dryers, parts and other equipment from point A to point B. This can involve equipment transportation, warehousing and more. We offer all kinds of service within road freight, sea freight or air freight. We are [...]

Erection and commissioning of a sand dryer

Erection and commissioning of a sand dryer: We offer assistance with erection and commissioning of the fluid bed dryer equipment. Also we can give operator training, technical/maintenance training, machine process training and safety training. Our fluidized bed dryers are constructed from the highest quality materials and are guaranteed to provide a lasting return on the investment. The mineral dryers operate at temperatures up to 600° [...]

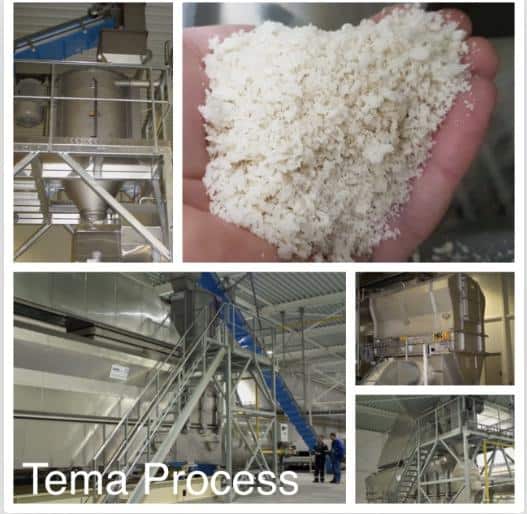

Leading supplier of breadcrumb, panko and rusk production lines

TEMA Process is the leading supplier of breadcrumb, panko and rusk production lines (drying/toasting/cooling). Bread crumbs have three basic uses: coating, binding and topping. The TEMA production line can be delivered in sizes ranging from 500 kg/hr to 6.000 kg/hr output. For energy savings the fluid bed dryer is equipped with an integrated heat recovery system.

Turnkey installations

TEMA Process has the experience and capacity to perform turnkey installations for the complete scope of the project including erection, commissioning, construction, training and maintenance. The TEMA Process bed systems are mainly used for thermal processes, such as: • Drying (to remove liquid from product by evaporation) • Cooling (usually after a drying process, so that the dryer and cooler can often be integrated in [...]

SEA Salt drying

SEA Salt drying: Sea salt is a natural salt originating from the evaporation of sea water by the effect of sun and wind that crystallizes into grain sea salt collected by mechanical system, without any other process that alters its natural properties and original chemical composition. Depending on the moisture content and the size of grain, the sea salt can be classified into Wet Sea [...]

fluid bed dryer for breadcrumb

TEMA Breadcrumb Processing line. Much of breadcrumb production worldwide is dedicated to processed foods either as a coating, called breading or crumbing, or as a filler to add inexpensive bulk and flavor. A Tema bread crumb / rusk process production line consists of a bread mill, a fluid bed dryer/cooler, gas burner, supply fan, recirculation system, exhaust blower, cyclone(s), cooling fan with filter, ductwork and [...]

Erection of NEW sterilizer in Europe

Erection of NEW sterilizer in Europe ! Natural Steam Sterilization: - For Spices, Herbs, Seeds & Nuts. - Minimal impact on Color and Flavor. - No radiation and chemical free. - Sanitary Clean-in-Place (CIP) design. - Continuous, repeatable and verifiable process. - 5 log kill. - Data logging for traceability. * TEMA Process is member of ESTA, ASTA and Royal Dutch Spice Association

Fluid bed dryers

The Tema Process fluid bed dryers are used in the mineral processing industry and in recycling operations, fluidised bed dryers prove their extraordinary abilities. The systems are used for drying pourable and abrasive wet materials, like sand, limestone, kaolin, talc, slag sand, ceramics, aggregates, bentonite, feldspar, quartz, etc. The high rate of heat transfer and material transport in the fluidised bed means that small driers [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety