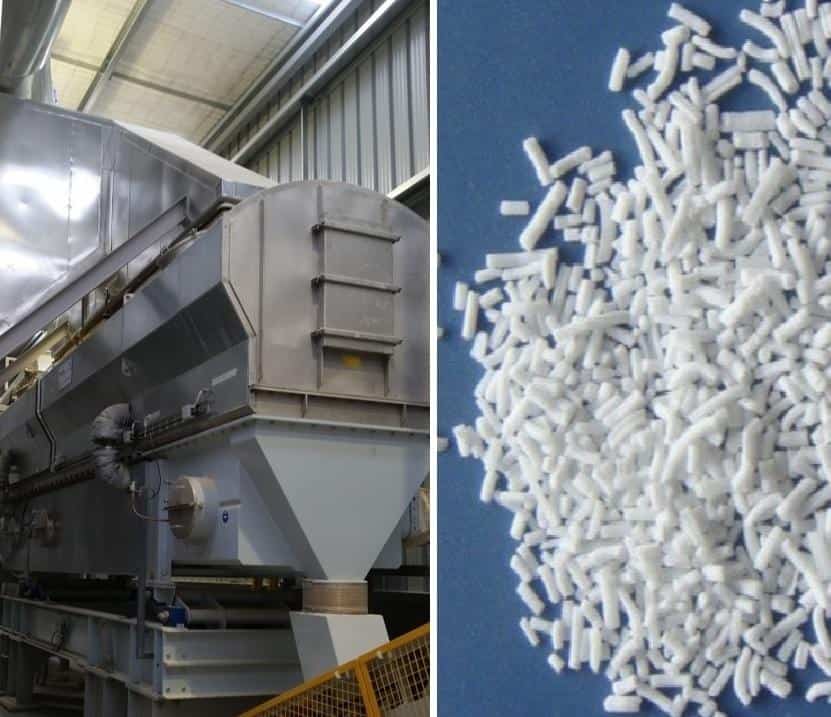

Drying and/or cooling of Sodium lauryl sulfate (SLS)

SLS is an detergent and surfactant is found in many personal care products (soaps, shampoos, toothpaste etc.) SLS Needles is a superior raw material for building compounds in industrial and household cleaning applications. TEMA Fluid bed technology is used for drying and/or cooling of SLS. The air which is used in the fluid bed performs two functions. First, the air flows through the layer of [...]

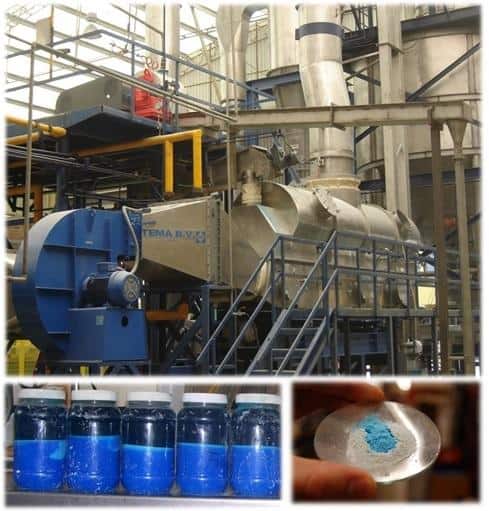

Copper Sulfate drying

Copper sulphate/sulfate, blue stone, blue vitriol are all common names for Copper Sulfate Pentahydrate (CuS04.5H20), which is the best known and the most widely used of the copper salts. Copper Sulfate drying: The pentahydrate (CuSO4·5H2O), the most commonly encountered salt, is bright blue. Copper sulfate is produced industrially by treating copper metal with hot concentrated sulfuric acid or its oxides with dilute sulfuric acid. Copper [...]

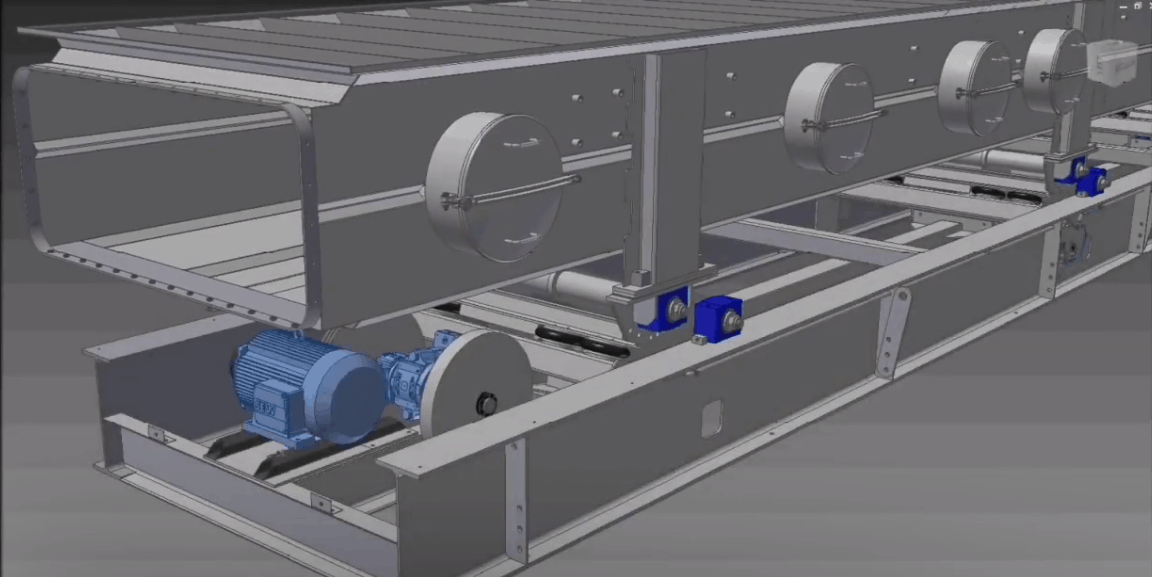

Twin Sand Fluid Bed Dryers/Coolers [video]

New Twin Sand Fluid Bed Dryers/Coolers for a client in Belgium. The sand needs to be dried to the required moisture content before it can be sold or further processed. The moisture content in sand from stockpiles can vary from 4% to 8%. The sand drying system are typically specified to reduce output moisture content to 0.5%.

Custom made fluid bed systems for Thermal Treatment of Food products

Custom made fluid bed systems for Thermal Treatment of Food products. Fluid bed dryers are not only used for drying but also used for cooling, roasting, cooking, puffing, sterilizing, stripping or baking of food products (breadcrumb, lactose, lemon peel, meat products, starch, seeds, spices, cocoa, cereals, rice,sugar, salt etc.) Customer made dryers are specially designed to dry at a precise temperature and humidity level that [...]

KCl drying: Potash

KCl drying: Potash is typically rich in potassium chloride (KCl), sodium chloride (NaCl) and other salts, and is obtained by dissolution mining and evaporation methods from brines. Approximately 95% of potash production is fertilizer used for agricultural purposes. The most common form of potash fertilizer is potassium chloride (KCl) but can also include potassium carbonate (K2CO3), potassium sulfate (K2SO4), or potassium nitrate (KNO3). After potash [...]

Commissioning Sea Salt (NaCl) TEMA Process Fluid Bed Dryer

Sea salt is salt produced from the evaporation of seawater. Its use is practical only in warm climates where the evaporation rate exceeds the precipitation rate, either annually or for extended periods, and ideally, where there are steady prevailing winds. When an adequate layer of salt has built up on the pan floor, harvesting commences. A machine digs up the salt, deposits it onto a conveyor [...]

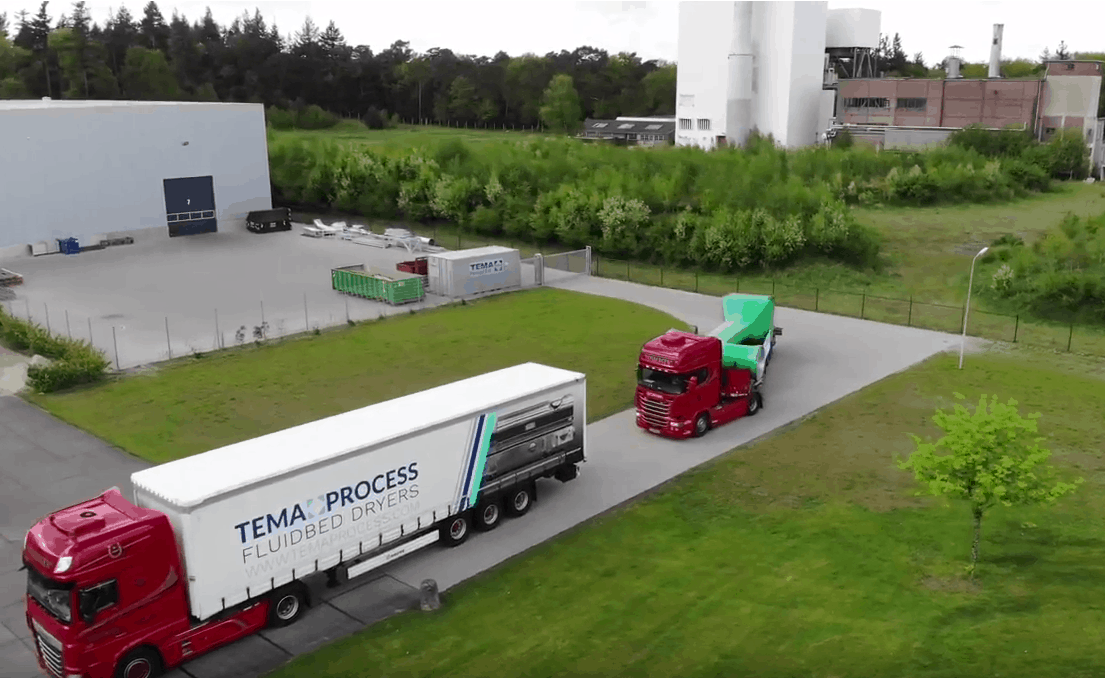

Transportation of fluid bed dryers/coolers worldwide [video]

Transport: approx. 95% of all our fluid bed dryers/coolers is exported (worldwide). The mode of transportation is an important consideration when planning the shipment process. Besides the costs, the urgency of the shipment, the value of the goods being shipped as well as the size and weight of the goods need to be evaluated when determining the form of transportation.

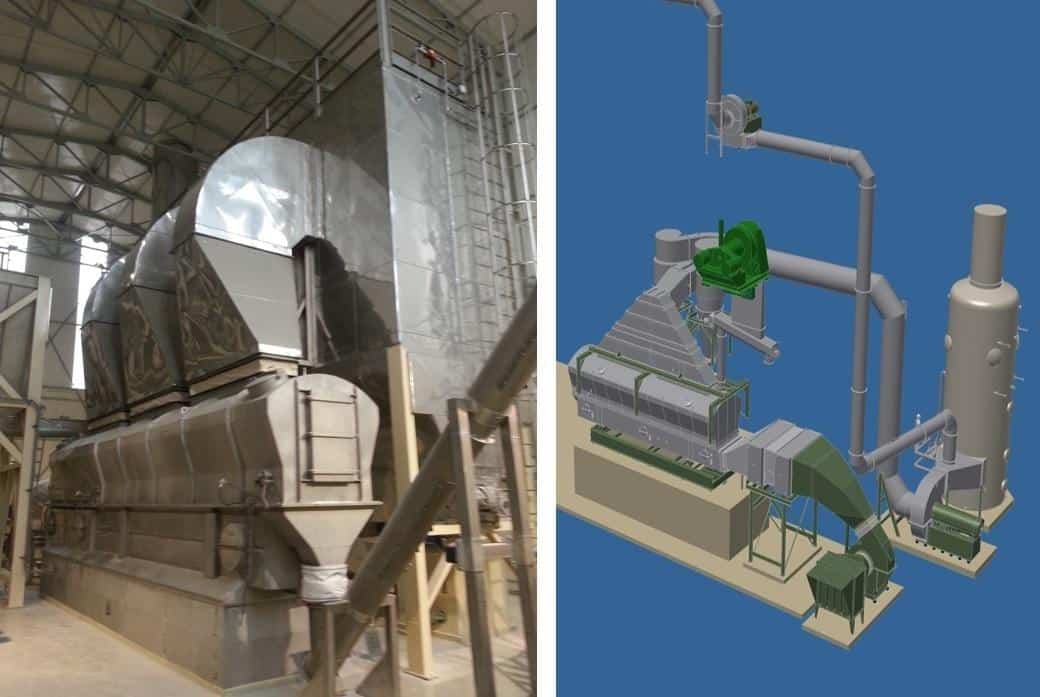

Tema Process Dust Collection & Gas Scrubbing

TEMA Dust Collection & Gas Scrubbing equipment and systems for emission control, gas cleaning and product recovery. Tema Process Dust Collection & Gas Scrubbing Line for the TEMA fluid Bed dryers include: Jet bag-Filters Cyclones Venturi Scrubbers Packed Tower Scrubbers Dry Scrubbers Cyclones in combination with Jet bag Filters Cyclones in combination with Packed Tower Scrubbers Venturi scrubbers are used to remove particulate matter from [...]

Lactose drying: hygienic Fluid Bed Dryer for the drying of Lactose

Lactose drying: Lactose is a disaccharide. It is a sugar composed of galactose and glucose. Lactose makes up around 2–8% of milk (by weight). TEMA Process engineered, manufactured and installed a hygienic Fluid Bed Dryer for the drying of Lactose. The rapid heat and mass transfer rates between the product and the drying medium and rapid mixing of solids which leads to nearly isothermal conditions [...]

Sand mining and drying with Fluid bed dryers by Tema Process [video]

Fluid bed dryers are the industrial dryers of choice when it comes to drying of sand. The sand fluid bed drying equipment is able to process both construction sand and frac sand effectively. Typically, the sand is mined, washed and screened and stored in piles for supply of various grades. The sand needs to be dried to the required moisture content before it can be [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety