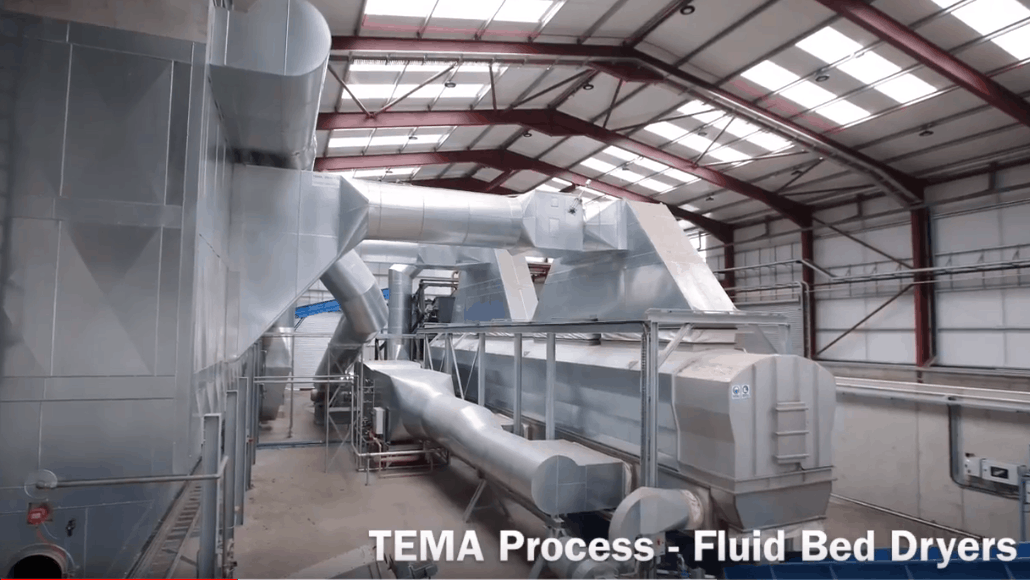

Old fluid bed dryers replaced by latest generation of TEMA Fluid Bed Dryers [video]

Busy times ! At the moment our service organisation is very busy with replacing old fluid bed dryers from our competitors. These dryers are at their end of their life cycle and are replaced by latest generation of TEMA Fluid Bed Dryers.

TEMA Process member of the European and American spice association

ASTA works to ensure the supply of clean, safe spice, shape public policy on behalf of the global industry and advance the business interests of its members and is the voice of the US spice industry in the global market. TEMA Process is a member of the ASTA and ESA (European Spice Association) and is specialized in Sterilization and Pasteurization systems for decontamination of spices, [...]

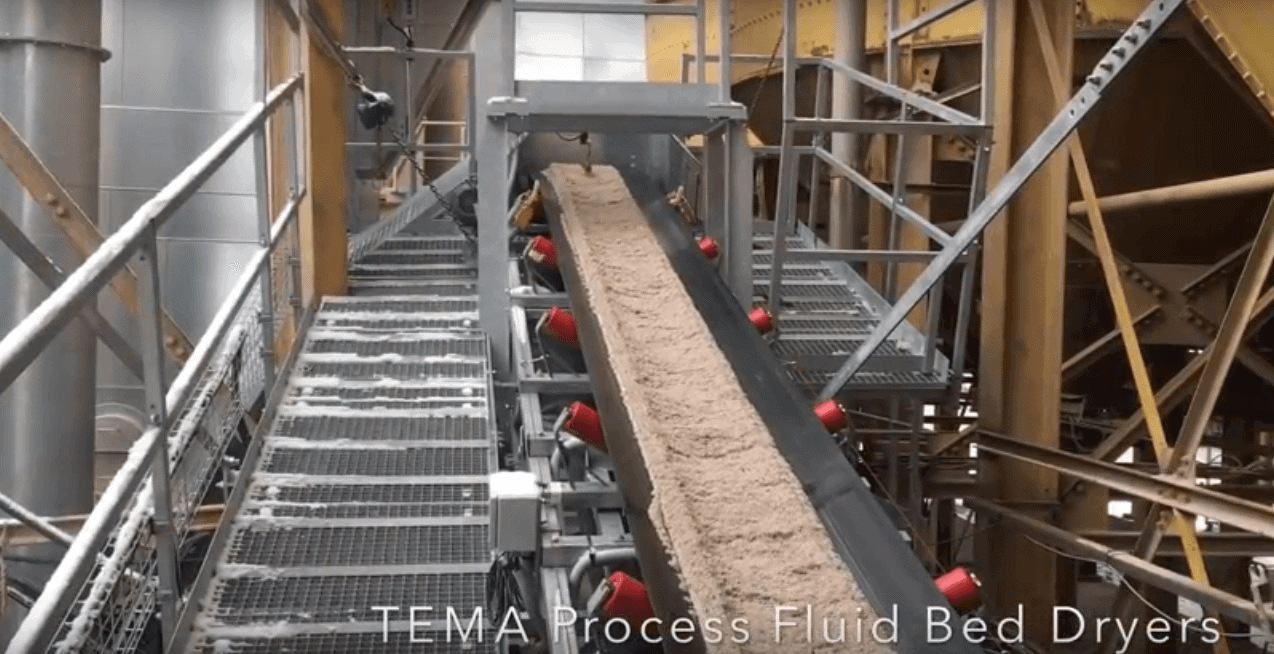

Bread crumb & rusk processing equipment

A Tema bread crumb / rusk process production line consists of a bread mill, a tema fluid bed dryer/cooler, gas burner, supply fan, recirculation system, exhaust blower, cyclone(s), cooling fan with filter, ductwork and control system. Bread mill: after baking, the bread is cooled down and milled in the Tema Bread mill. Milling screens determine the quantity of large/ small particles into the dryer.

Refuse-derived fuel dryer ready for shipment

Our TEMA PROCESS low temperature fluid bed dryer suitable for drying RDF and SRF for the production of secondary fuel from MSW. The heating takes place with waste heat from a CHP running on landfill gas. So noenergy gets lost.

Quartz sand high temperature dryer [video]

High Temperature, low energy dryer High temperature drying at up to 600°C: This results in greater evaporation per square metre of bed without an increase in air volume, reduces the power consumption per tonne of sand dried and improves fuel efficiency. The TEMA Fluid Bed dryer is split into two sections, the first of which operates at a high temperature (up to 600°C). In the [...]

continuous fluid-bed dryer/cooler

A fluid bed dryer can handle up to 200 t/h and is used for drying of clay, sand, gravel, limestone, etc. A continuous fluid-bed dryer/cooler is a machine in which a continuous flow of damp, granular material is conveyed over a perforated bed, through which air is blown to bring about fluidization. The material is dried in the first section of the machine and cooled [...]

Drying Refuse derived fuel [video]

DRYING RDF (Refuse derived fuel) : TEMA Process has already built several fluid bed dryers for drying large volumes of mixed waste streams and has an extensive experience with the material behaviour during drying. Waste is considered as valuable raw material for the production of energy. The use of fuels with a high moisture content decreases the overall energy efficiency of the power plant and [...]

Watch our brand new video’s!

We have made some great new video's. You can find them below.

Welcome to our brand new website!

Hello everyone! Welcome to the brand new website of Tema Process. Here you can find all about us, we will post news and you can scroll through the menu for more info! Thanks for checking the new website.

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety