Safer Meat: How Dehumidification Prevents Condensation in Processing Plants

In meat processing, temperature control gets a lot of attention, but humidity control is often the missing piece. When humidity rises, you start seeing the classic symptoms: condensation on cold products, water dripping from ceilings, fogging and even icing in certain zones. These moisture issues don’t just look bad; they can increase hygiene risks, disrupt production, and create an uncomfortable work environment. TEMA Process designs [...]

Early Detection and Prevention of LiCl Leakage

Lithium Chloride (LiCl) is a highly effective liquid desiccant for precise humidity control. In a liquid desiccant dehumidifier, the LiCl solution continuously circulates between the dehumidifier and the regenerator to maintain stable air conditions. TEMA Process designs, builds, and installs its own LiCl dehumidification systems, and supports customers with installation and commissioning worldwide. With the right maintenance, these systems remain highly energy-efficient for drying and [...]

From Crystallization to Product Handling: Efficient Sodium Sulfate Drying and Cooling

Sodium sulfate (Na₂SO₄) is a common component in industrial wastewaters, particularly from flue gas desulfurization (FGD) plants. To meet increasingly strict discharge regulations, sodium sulfate is often removed by crystallization and, in many cases, recovered as a valuable product. The same separation challenge is well known in industries such as viscose fiber production. Depending on process conditions, sodium sulfate can be crystallized either as an [...]

TEMA Process: Your Strategic Partner for Gelatin Drying and Turn-Key EPC Solutions

TEMA Process: Your Strategic Partner for Gelatin Drying and Turn-Key EPC Solutions In the gelatin industry, drying is a critical step that directly impacts product quality, consistency, and operating costs. Gelatin and collagen-based products are widely used across food, pharmaceutical, and cosmetics applications—making reliable, controlled drying essential. At TEMA Process, we specialize in gelatin drying and act as a trusted EPC contractor for turn-key gelatin [...]

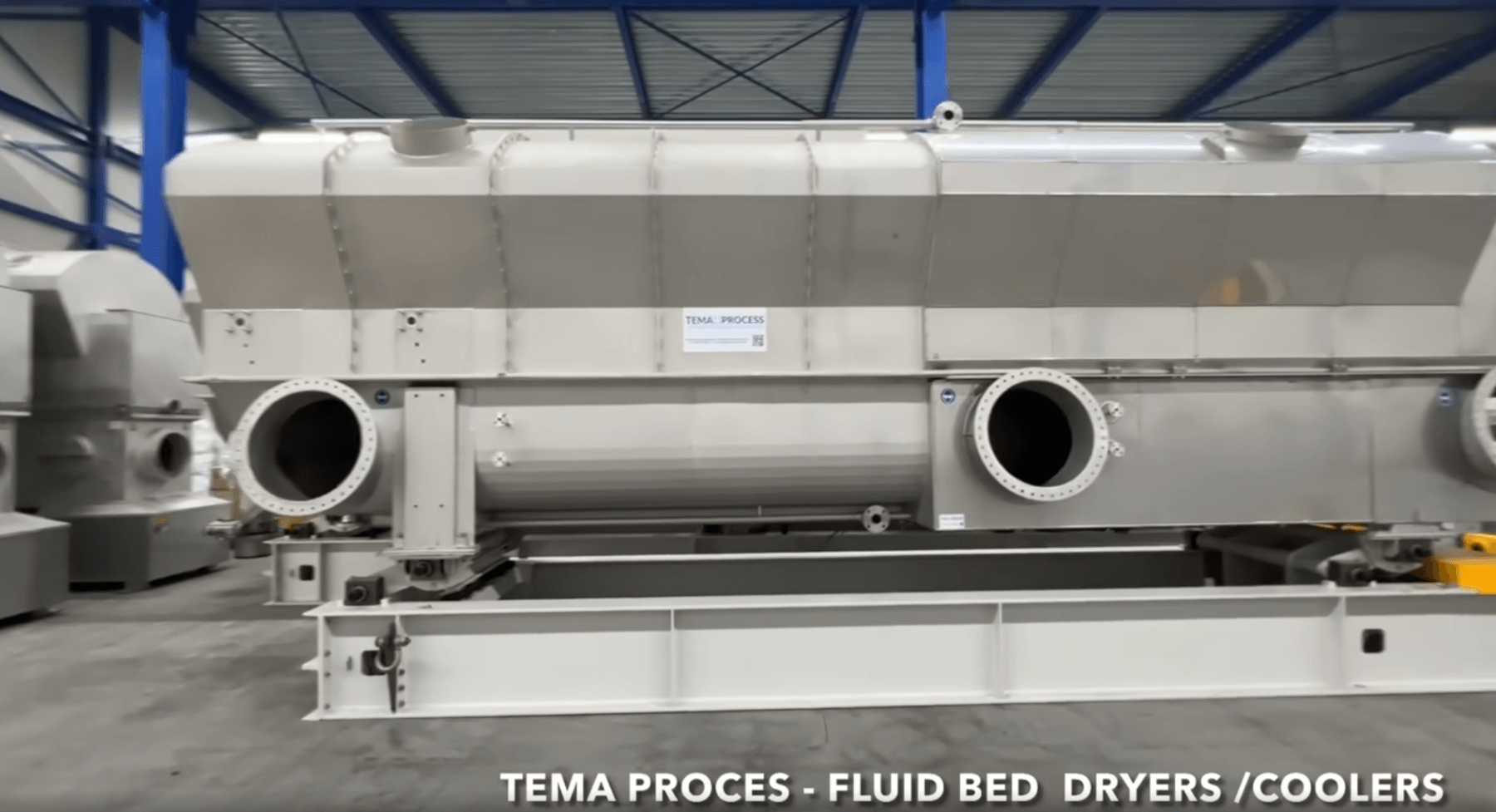

Tema Process on Fluid Bed Drying Solutions for Recovered Carbon Black

Our colleague Koen Egberts shared how fluid bed dryers boost drying performance, energy efficiency, and consistency in rCB production — a critical step in sustainable carbon black recovery. Koen Egberts Explains how Fluid Bed Dryers Improve rCB Drying Efficiency Tema Process were attending and exhibiting at the conference to present their Fluid Bed Dryer Solutions. “Events like this are key to staying connected with market [...]

Chicken Manure as a Valuable Resource with TEMA Process Fluid Bed Dryers

Chicken manure is no longer just a waste product — it's a valuable resource. At TEMA Process, we're proud to provide energy-efficient fluid bed drying systems that convert high-moisture poultry manure into dry, hygienic material suitable for use as organic fertilizer. -High thermal efficiency - Sustainable agriculture & circular economy -Proven technology in demanding environments Our drying systems are designed for continuous, fully automated operation, [...]

Erection of a TEMA Process Fluid Bed Drying System with Baghouse Filter

The successful installation of a fluid bed drying system starts with a structured and well-planned erection process. At site, foundations and steel support structures are prepared according to layout drawings. The fluid bed dryer is then positioned and aligned, followed by installation of internal components such as the air distribution plenum, perforated air deck and discharge sections. Next, the process air system is erected, including [...]

Chemicals commonly dried in fluid bed dryers

Fluid bed dryers are widely used in the chemical industry to dry powders, crystals and granules with precise moisture control and uniform product quality. Typical applications include: – Inorganic chemicals – ammonium sulfate, ammonium nitrate, sodium salts, potassium salts, copper sulphate, lithium carbonate, lithium hydroxide – Organic chemicals – organic acids, chemical intermediates, detergent ingredients – Plastics, polymers & resins – plastic granules, polymer powders, [...]

Applications of fluid bed dryers & coolers

Fluid bed dryers and coolers are widely used to dry, cool and condition powders and granules with uniform product quality and high energy efficiency. They are applied across multiple industries, including: - Food & feed – breadcrumbs, cereals, starches, sugars, additives - Chemicals – crystals, powders, polymers, specialty chemicals - Nutraceuticals – granules, pellets, excipients - Minerals & mining – sand, ores, mineral concentrates - [...]

Drying citrus pulp for pectin production

Citrus pulp is a valuable by-product from juice processing and a key raw material for pectin. To preserve pectin quality, controlled and uniform drying is essential. With a TEMA Process fluid bed dryer, citrus pulp is dried gently and efficiently, ensuring: - Uniform moisture reduction - Protection of pectin functionality - Stable processing of sticky, sugar-rich materials - Energy-efficient, continuous operation Integrated drying and cooling [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety