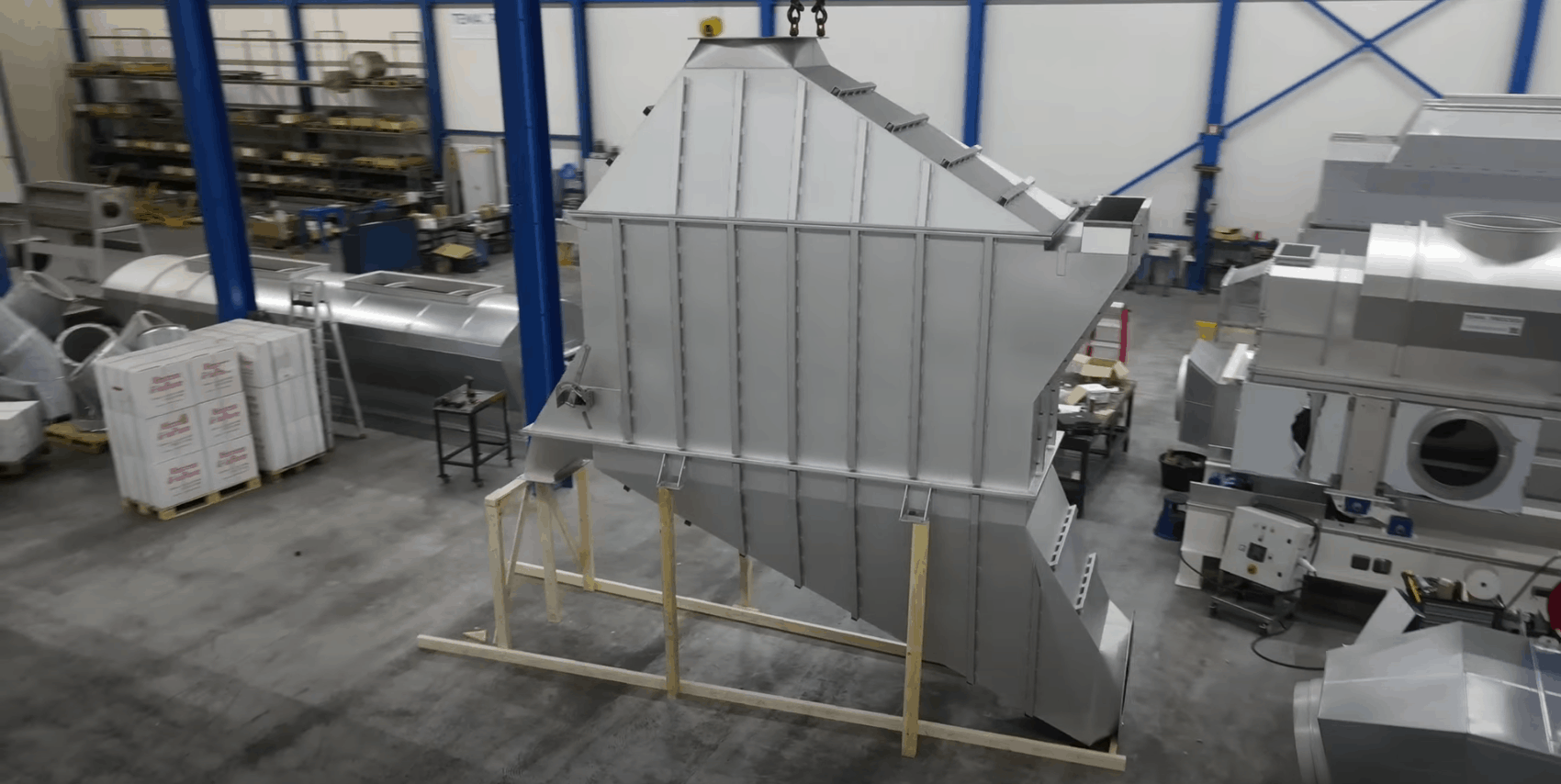

Tema Fluid Bed dryer for spray dryer

Tema Fluid Bed dryer for spray dryer. The two stage drying process is superior to the traditional single stage drying in terms of product quality and cost of production. The two stage dryer consists of a spray dryer with an external shaking fluid bed placed below the drying chamber. The product can be removed from the drying chamber with a higher moisture content, and the final [...]

Static (non-shaking) fluidised bed

Static (non-shaking) fluidised bed or fluid bed (dryers and coolers) are used on free flowing fluidised bulk materials that have a narrow particle size distribution. The static fluid bed remains stationary during operation. Static fluid bed dryers can be continuous or batch operation and may be round or rectangular. The other type of fluid bed dryer is a shaking fluid bed dryer or cooler, where the body [...]

TEMA Pulse Jet bag filter systems

The TEMA Pulse Jet bag filter systems are used to separate the dust from the exhaust air which is coming from the fluid bed dryer/cooler. The bag filters can be delivered in standard design or tailor-made specifically designed for the customers application. In the pulse jet bag filters, the bags are cleaned by injecting compressed gas. The filters range from 15 m² up to 1.200 [...]

Installing ThermoSeed equipment at Vihervakka Finland

Seed treatment without chemicals: ThermoSeed uses the innovative thermal disinfection tool which applies hot humid air to the seeds as a form of steam pasteurization. […]

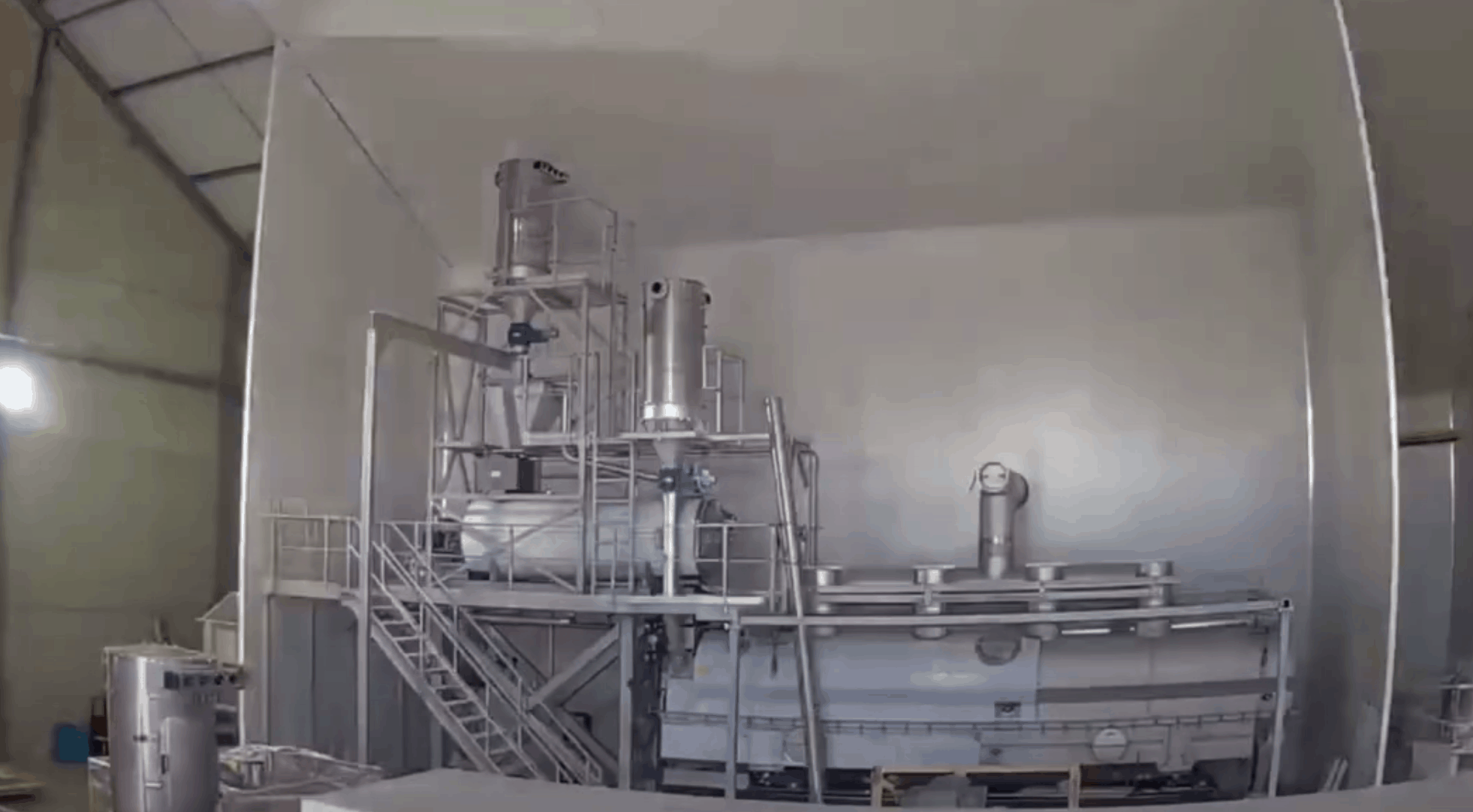

Time lapse: Tema steriliser

Erection of a Tema Process Steam steriliser for spices, seed and herbs. […]

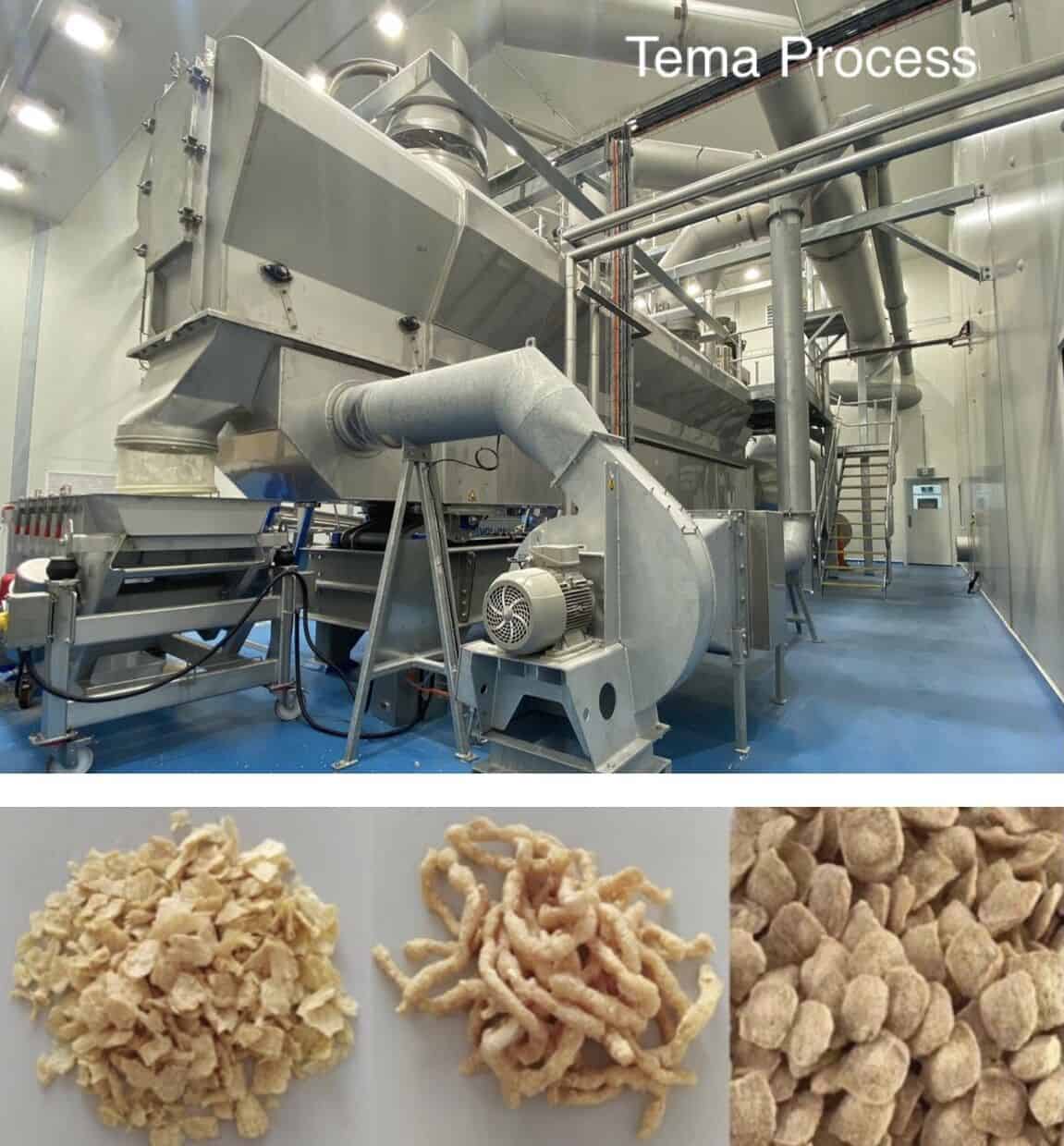

Meatless Fluid bed dryer Tema Process

Meatless Fluid bed dryer Tema Process video […]

Drying of Extruded food & feed products

Extrusion is a mechanical process in which food or feed materials are forced, under pressure, through a die opening to create products of a desired shape, size, and/or texture. In the case of food production, if the food is heated by external heaters during the process, it is referred to as extrusion cooking, a relatively new and advanced food processing technique. Due to its processing [...]

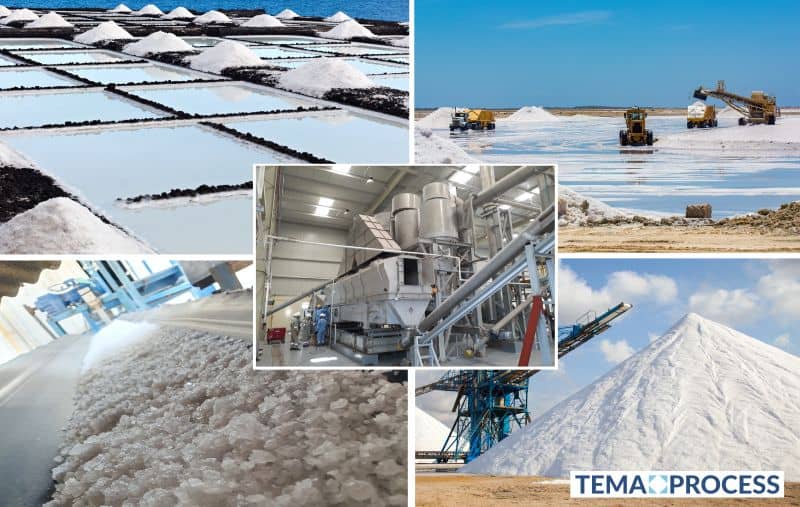

Salt centrifuge & drying

Tema Process is the liquid/solid separation solution provider for Salt production and processing plants. Salt is the common name for the substance sodium chloride (NaCI), which occurs in the form of transparent cubic crystals. Salt centrifuge The Siebtechnik Tema centrifuges are used for continuous solid-liquid separation and provide a long holding time, low material loss and low crystal breakage. The centrifuge enables the salt to be dewatered [...]

Dryer/cooler process, how does it work?

Fluid bed Process. I often get the questions : What does fluidised bed mean? How does a fluidisation work? What is the purpose of fluidisation? Etc. In a couple of chapters, I like to explain more about this technology/process and where the system can be used. […]

Tema Process Sea Salt Dryer

Production of sea salt begins with evaporation of sea water in shallow pools and ends with the harvest, washing, drying and packing of salts. […]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety