Soybean processing and drying equipment [video]

Soybean processing and drying equipment. Soybean meal is an ideal protein supplement for all types of cattle feed. In the Tema process workshop the cookers and fluid bed dryers are assembled prior to the shipping. The FAT (Factory Acceptance Test) is to check the functionality and capabilities of the equipment.

Aspartame and dextrose dryers (corn derivative) with C.I.P. [video]

Aspartame and dextrose dryers (corn derivative) with C.I.P. The Tema fluid bed bed dryer is used to dry, and/or cool powders or granules. It is can be used downstream of a spray tower dryer to process powder at outfeed. Depending on the characteristics of the product to be fluidized (density, grain size distribution, etc.) the right fluid bed configuration is selected. Clean-in-place (CIP) is a [...]

Tema Gelatin belt/tunnel dryer

The gelatin solution is chilled and extruded as noodles, and the gelled material is deposited as a bed onto a stainless steel plate belt. The belt is passed through a drying chamber, which is divided into zones in each of which the temperature and humidity of the drying air is accurately controlled. Typical temperatures range from about 32° C in the initial zone up to [...]

Natural sterilization/pasteurization of products with pure steam

Food safety ! Natural sterilization/pasteurization of products with pure steam has gained significantly in popularity with the introduction of the continuous HT-ST “In-Flow” steam decontamination process. The very short contact (20-40 seconds) with high pressure steam (autoclave) at a temperature that may vary between 102°C and 122°C makes it possible to decontaminate heat sensitive food products without adverse effect on quality. After the thermal steam [...]

China clay dryer (Kaolinite)

NEW China clay dryer. China clay is also known as Kaolinite or Kaolin Al2(OH)4Si2O5. Kaolinite is one of the most common minerals; it is mined in Malaysia, Pakistan, Vietnam, Brazil, Bulgaria, Bangladesh, France, the United Kingdom, Iran, Germany, India, Australia, South Korea, the People's Republic of China, the Czech Republic, Spain, South Africa, and the United States. The main use of the mineral kaolinite (about [...]

NEW: Cooled Bed Plate for the Tema Process fluid bed dryer [video]

Heated process air is supplied to a special perforated distributor bed plate. Via the bed plate the hot air flows through the layer of solids at a velocity sufficient to support the weight of particles in a fluidized state. The heat in the air is used to evaporate moisture from the product. The drying air picks up moisture and cools down during the evaporation. This [...]

Drying minerals with a heavy-duty Tema Fluid Bed dryer

Drying minerals with a “heavy-duty” Tema Fluid Bed dryer. In the first stage of drying, free (surface) moisture is removed from the product and all available energy supplied as heat (gas burner) in the drying air is used for evaporation. The temperature of the air moving through the fluidized bed drops as it absorbs moisture up to its saturation point. If there is a change [...]

Sodium Sulfate drying using Fluid bed dryers

Sodium Sulfate Na2SO4 drying. Fluid bed dryers are today's standard of technology for drying and cooling of all kind of salts. Sodium Sulfate: the largest use is as filler in powdered home laundry detergents, consuming approx. 50% of world production. The glass industry provides another significant application for sodium sulfate.

Poultry manure dryer

Chicken manure is the feces of chickens used as an organic fertilizer, especially for soil low in nitrogen. Of all animal manures, it has the highest amount of nitrogen, phosphorus, and potassium. Chicken manure is sometimes pelletized for use as a fertilizer, and this product may have additional phosphorus, potassium or nitrogen added. Optimal storage conditions for chicken manure includes it being kept in a [...]

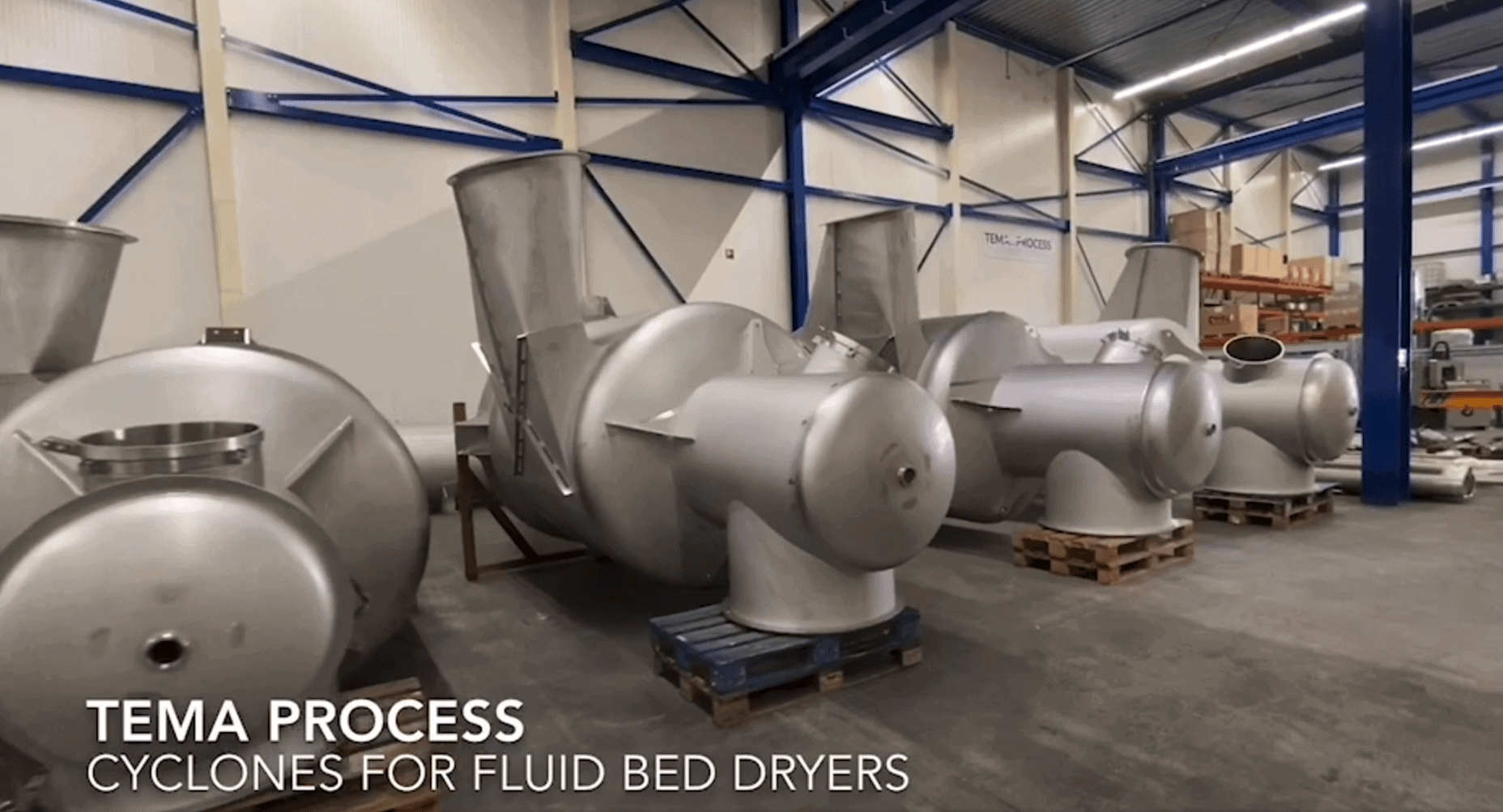

TEMA Process Hygienic Cyclones

TEMA Process Hygienic Cyclones are used to separate the fine particles from the exhaust air of the fluid bed dryer/cooler and full fills the requirements for use in highly sanitary applications in industries such as food and chemical industry. Tema engineers and manufactures sanitary cyclones according to the requirements of the food and dairy industry, including a wide range of sanitary and industrial Clean-in-Place (CIP) [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety

![NEW: Cooled Bed Plate for the Tema Process fluid bed dryer [video]](https://temaprocess.com/wp-content/uploads/2020/06/NEW-Cooled-Bed-Plate-for-the-Tema-Process-fluid-bed-dryer-video.png)