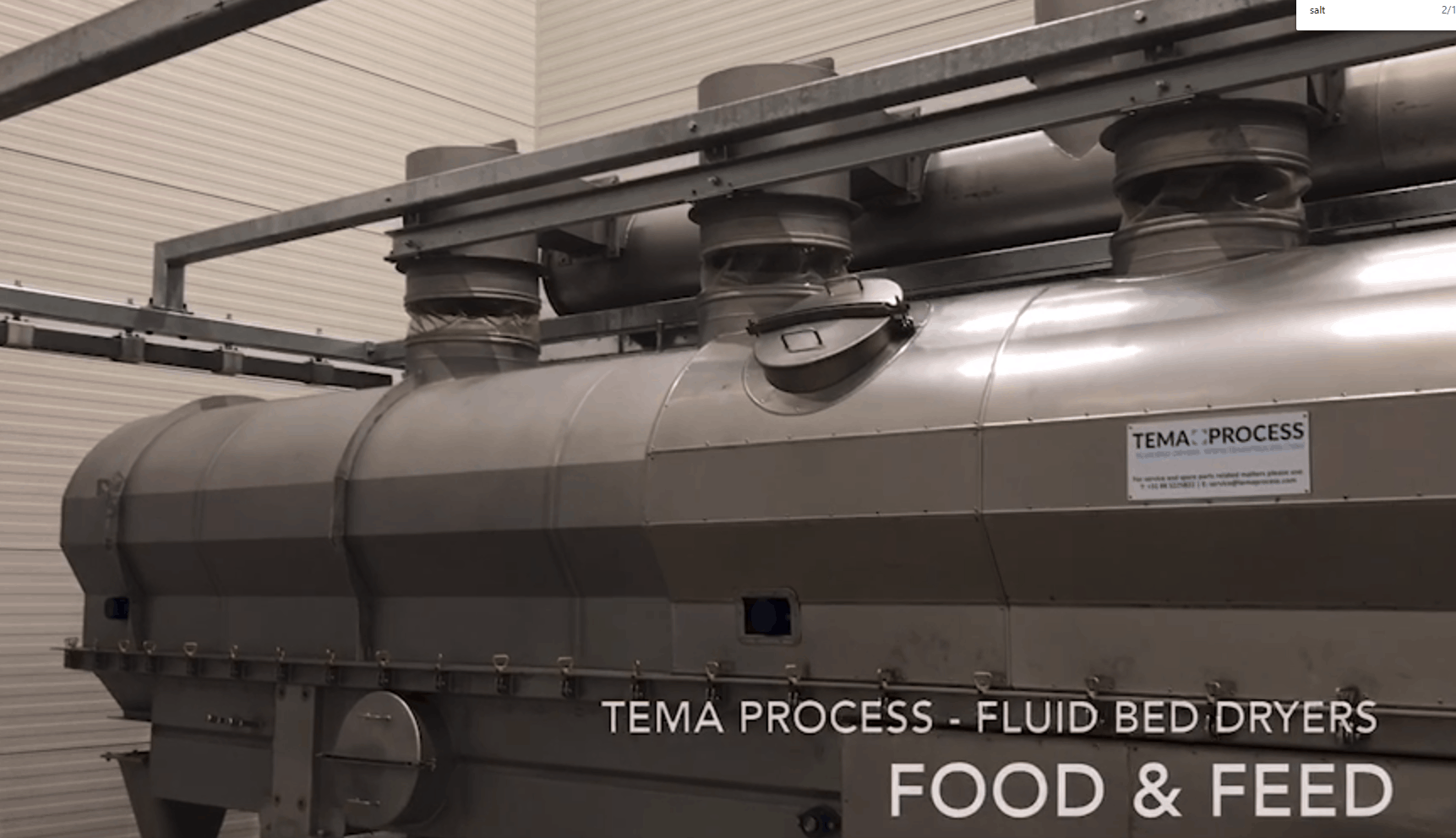

Food dryers ready for transport to China [video]

Four food dryers (total 8), ready for transport to China ??. Whenever a hygienic or sanitary design has high priority, fluid bed systems are the preferred solution in the food industry. The Fluid beds are used for drying, cooling, roasting, expanding, sterilizing and cooking. For gentle drying at lower temperatures and extended drying time, TEMA Process fluid bed dryers can use multiple temperature zones with [...]

Drying Textured or texturized vegetable protein (TVP)

Textured or texturized vegetable protein (TVP), also known as textured soy protein (TSP), soy meat, or soya chunks is a defatted soy flour product, a by-product of extracting soybean oil. But it can also be made from cotton seeds, wheat, and oats. It is extruded into various shapes (chunks, flakes, nuggets, grains, and strips) and sizes, exiting the nozzle while still hot and expanding as [...]

Drying Paper Sludge with Tema Process Fluid Bed Dryer

Drying Paper Sludge: Thermal Drying is used to dry the wastes to a much higher solids content, far beyond what mechanical dewatering (filter press) can produce. The advantages of heat drying include reduced product transportation costs, further pathogen reduction, improved storage capability, increased calorific value and marketability. 2x Fluid Bed Dryers for sludge in our workshop, ready for transport.

Salt drying. Commissioning a Tema Process dryer/cooler

Salt drying. Commissioning a Tema Process dryer/cooler. In solution mining, salt is extracted by forcing water under pressure into a bore-hole drilled into an underground salt bed or dome. The salt dissolves, turning the water into brine and creating a cavern in the salt-bed. The salt is produced by evaporating ‘solution-mined’ brine in pressure vessels – a process known as Vacuum Evaporation. For food and [...]

Assembling 4 TEMA Process fluidbed dryers for export to the USA.

Assembling 4 TEMA Process fluidbed dryers for export to the USA.

New Twin Sand Fluid Bed Dryers/Coolers with Jet-bag air filter!

New Twin Sand Fluid Bed Dryers/Coolers with Jet-bag air filter ! TEMA Process Fluid Bed Dryers for drying of all kind of minerals like: talc, sand, gravel, limestone, bentonite, feldspar, gypsum, salts, potash, mica etc. The Fluid bed dryers are used for processing natural materials, the systems are designed to minimize energy usage and are easy to maintain and operate, rigid construction for challenging environments.

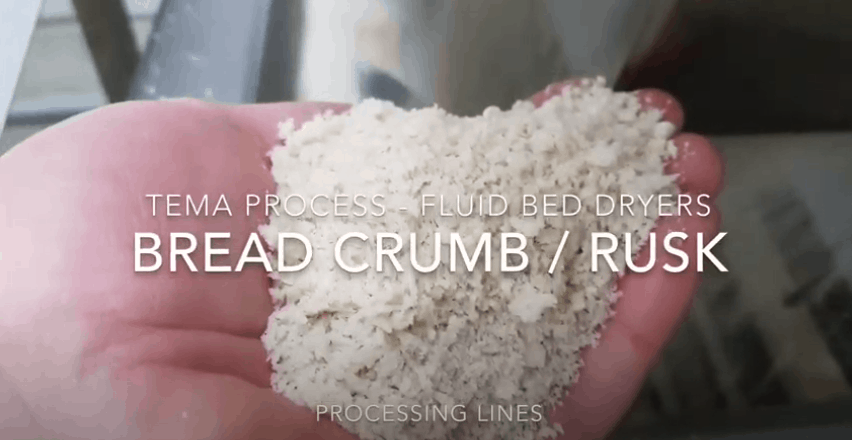

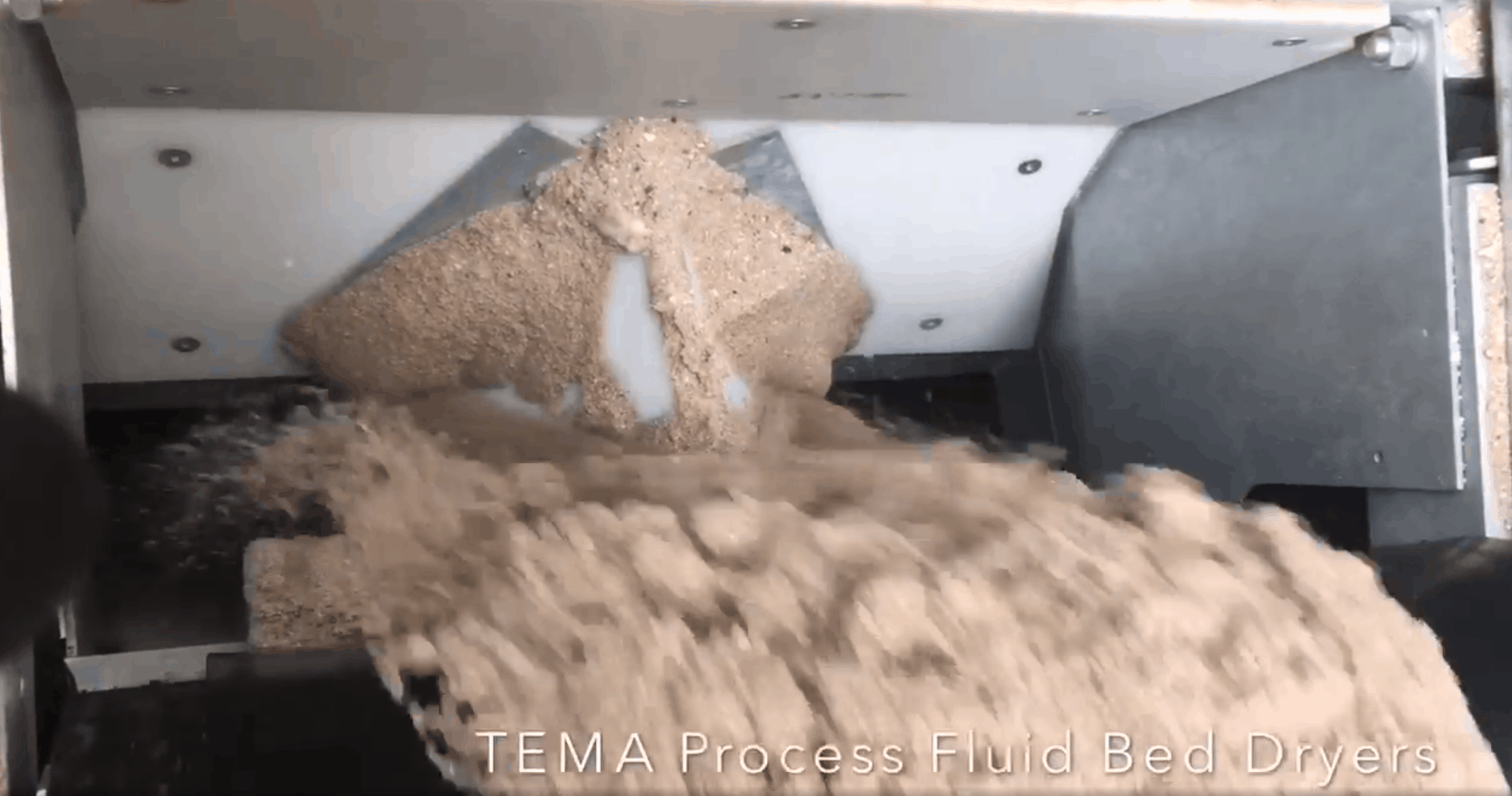

Breadcrumbs made by toasting the bread in the Tema Fluid bed dryer [video]

Breadcrumbs are made either by loaves or by sheeting, slitting and baking the dough followed by cooling, grinding, and drying the baked product. A golden coloured crust contributes colour to the breadcrumb. The crust is obtained either by the conventional baking process itself or by toasting the bread in the Tema Fluid bed dryer.

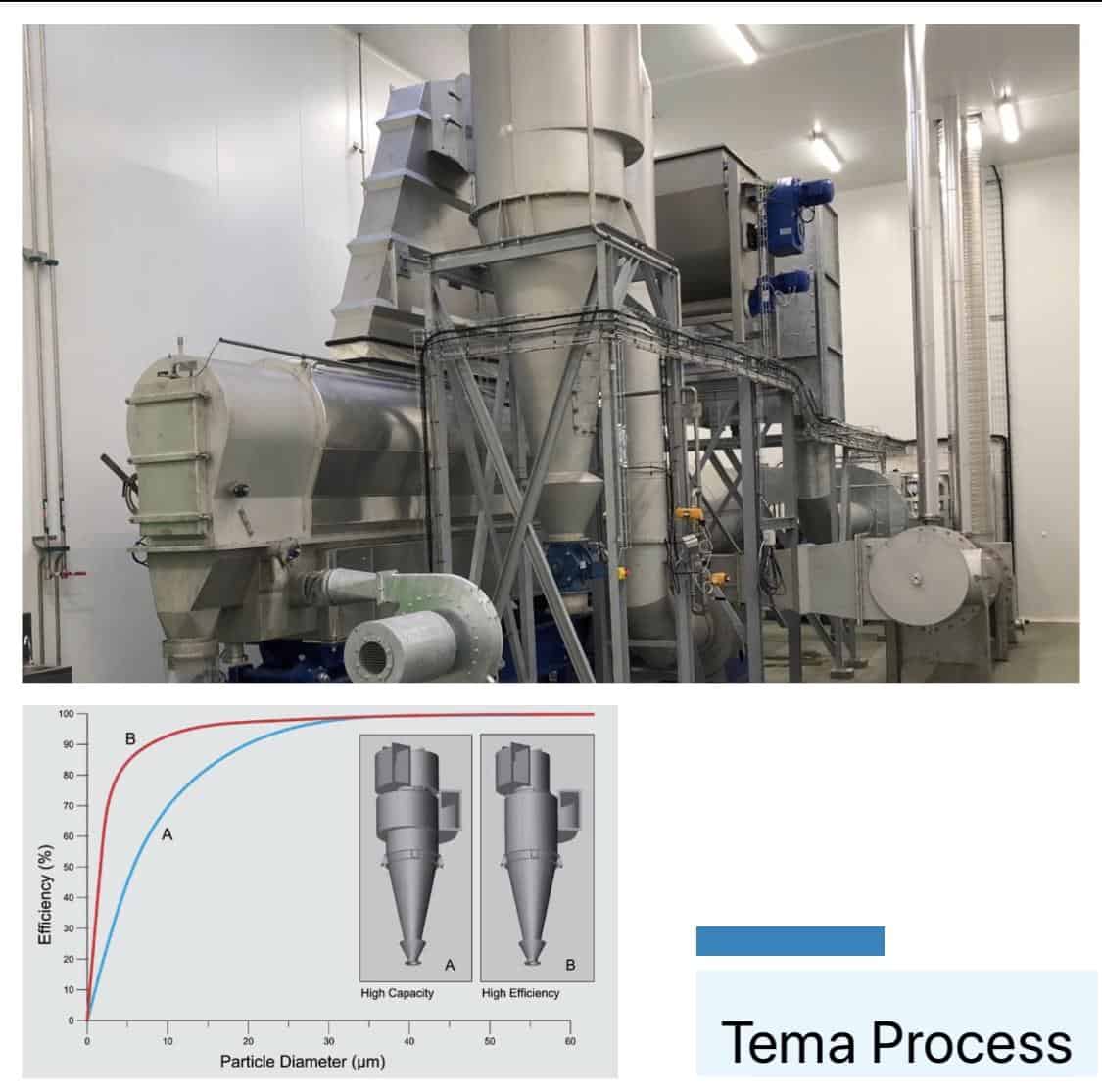

Fluid bed dryer/cooler exhaust system with cyclone

Fluid bed dryer/cooler exhaust system with cyclone. TEMA Process offers Dust Collection & Gas Scrubbing equipment and systems for emission control, gas cleaning and product recovery. A Cyclone is a relative simple device that uses centrifugal force to separate larger particles from air streams. It is a high capacity / high efficiency separator that also can be used in combination with Fluid bed Dryers / [...]

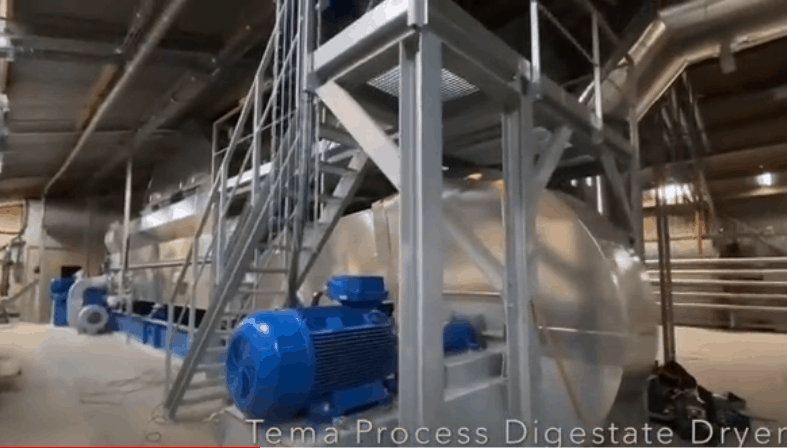

Commissioning Digestate Dryer [video]

Commissioning Digestate Dryer When an anaerobic digester processes organic material, it produces a gas (biogas) plus liquid and solid digested material. Those liquids and solids are called digestate. Raw or whole digestate produced by a biogas system is physically and chemically different from the organic input material used to produce. The digestate is dried on a Tema Process fluid bed dryer. Drying is accomplished by [...]

The design and flexible settings of the fluid bed system

The design and flexible settings of the fluid bed system (air speed, frequency of shaking transport system, air supply temperature etc.) is done with a fully understanding in regard to the proporties of the material that must be dried. Properties like: Product size, particle size distribution, density, stickiness, specific heat of the product its consistencies, product temperature, etc. The shaking motion improves the fluidization and [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety