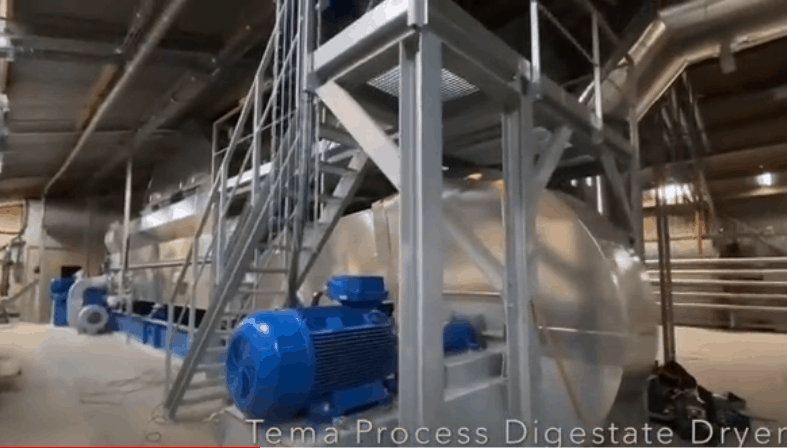

Commissioning Digestate Dryer [video]

Commissioning Digestate Dryer When an anaerobic digester processes organic material, it produces a gas (biogas) plus liquid and solid digested material. Those liquids and solids are called digestate. Raw or whole digestate produced by a biogas system is physically and chemically different from the organic input material used to produce. The digestate is dried on a Tema Process fluid bed dryer. Drying is accomplished by [...]

The design and flexible settings of the fluid bed system

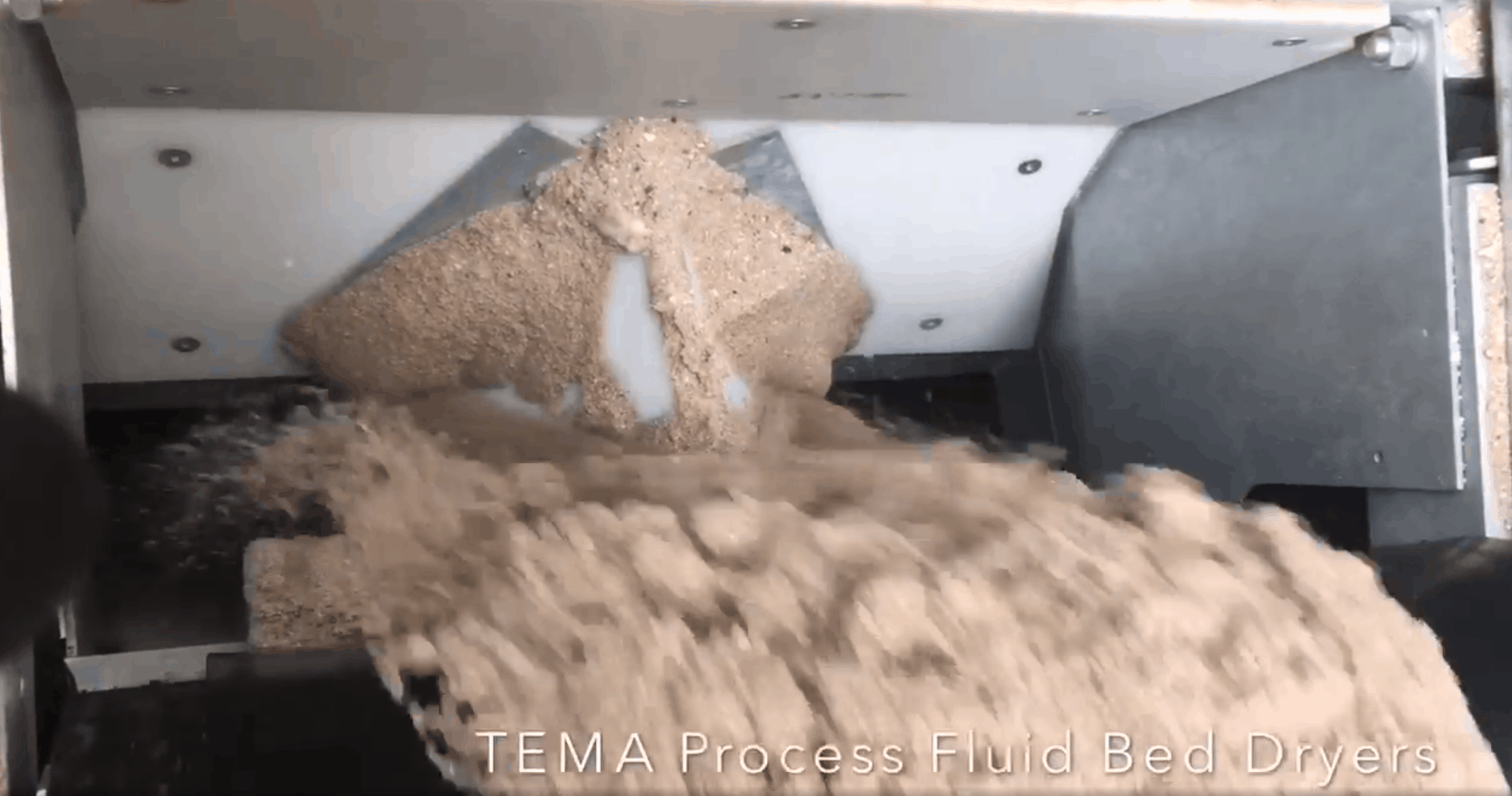

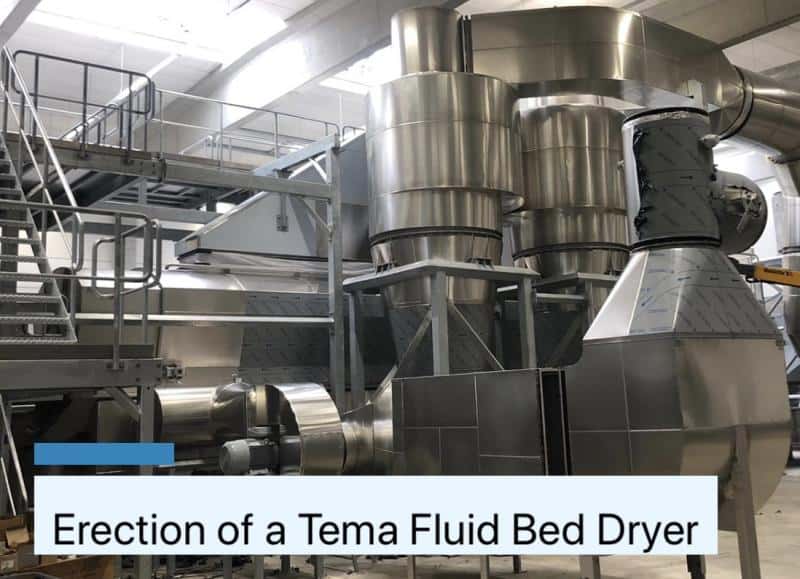

The design and flexible settings of the fluid bed system (air speed, frequency of shaking transport system, air supply temperature etc.) is done with a fully understanding in regard to the proporties of the material that must be dried. Properties like: Product size, particle size distribution, density, stickiness, specific heat of the product its consistencies, product temperature, etc. The shaking motion improves the fluidization and [...]

Drying extruded cereal and bread crumb products

Drying extruded cereal and bread crumb products: A extrusion line in combination with a fluid bed dryer transforms agriculture raw materials into edible crispy products. These products can vary in color, composition, format, taste, bite, and texture depending on market demand. The Tema Process production lines are available in a wide range of capacities starting from 500 kg/hr up to 6.000 kg/hr.

Drying Bentonite (clay) using Tema Process fluid bed dryer

Bentonite (clay) dryer: Bentonite is the commercial name of a whole range of natural clays with a high water absorption capacity causing it to expand and swell. Bentonites may contain in addition a variety of accessory minerals. These may include lesser amounts of other clay minerals such as kaolin, mica, illite, as well as non-clay minerals like quartz, feldspar, calcite, and gypsum. Uses: purification, drilling [...]

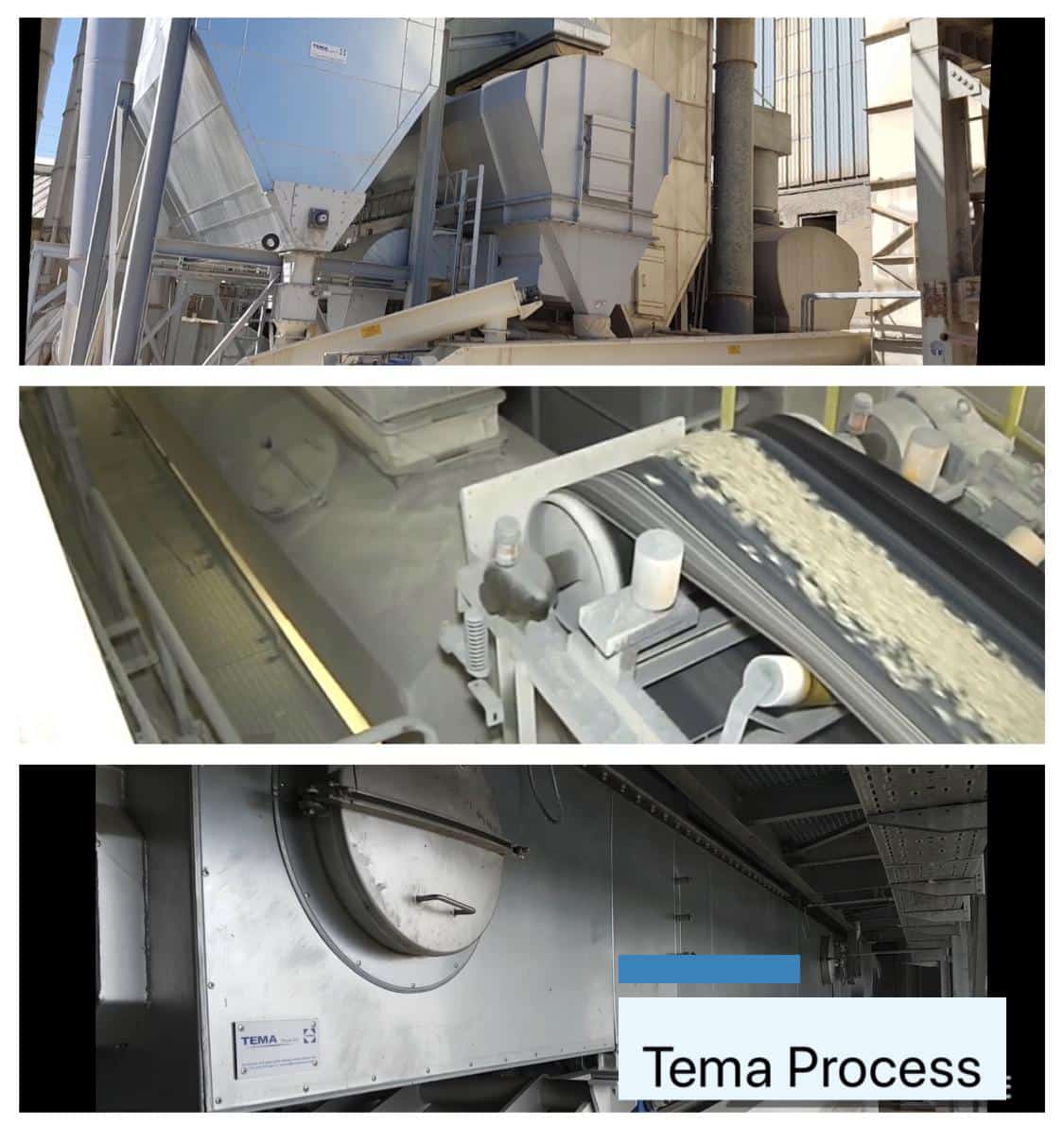

Fluidbed dryers/coolers are used for handling materials coming from quarries like dolomite, sand, limestone, gypsum, clay

Dolomite is a mineral composed of calcium magnesium carbonate, CaMg(CO3)2. Dolomite is used as a concrete aggregate and is a source for production of magnesium and glass. The fluidbed dryers/coolers are used for handling materials coming from quarries (dolomite, sand, limestone, gypsum, clay etc.). The selection/design of the fluid bed system is done with a full understanding in regard to the proporties of the material [...]

Using fluidized bed as a drying method for drying Sodium sulfate

Sodium sulfate (sulfate of soda , Na₂SO₄). The largest use is as filler in powdered home laundry detergents. It can also be used to add strength and toughness to paper and to make glass. During the drying process the bed temperature is uniform and the drying takes place at relative low temperatures. The fluidized bed drying is known as a drying method capable of efficiently [...]

Energy efficient drying of digestate from biogas plants and slurry from animal manure

Tema Process has developed a process for energy efficient drying of digestate from biogas plants and slurry from animal manure. The dried material can be converted either into organic fertilizer or fuel. Why drying: To reduce manure weight: reducing storage and transport costs. Eliminate issues surrounding wet manure / digestate (odours /ammonia / environmental).

advanced fluid beds for salt drying applications

Salt, or Sodium Chloride, is essential for life , weather for human beings or animals, and it’s history for production goes back a long time. Weather produced by natural evaporation in ponds, or mined as rock salt, in the upgrading process to clean salt crystals, salt drying is a crucial step. Tema Process supplies advanced fluid beds for salt drying applications ( sea-salt, rock salt [...]

Precise moisture level control with TEMA Fluid bed dryers

Precise moisture level control is for chemical products often a top priority in order to handle and preserve the quality of the material. Tema process supplies tailor made designed fluid bed dryers for individual chemical characteristics , of which drying behavior validated in our laboratory. The TEMA shaking mechanism allows to handle cake material and highly viscous chemicals. TEMA Equipment & Plants can be successfully [...]

Tema wide dust recovery hood captures airborne particles and returns it to the process [video]

Tema wide dust recovery hood captures airborne particles and returns it to the process. The Tema fluid bed dryers are equipped with a special designed wide hood that reduces the airflow velocity. As a result of this velocity drop, gravity takes over and the fluidised product will remain in the dryer. The expanded hood cuts the volume of product lost as waste and increases the [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety

![Tema wide dust recovery hood captures airborne particles and returns it to the process [video]](https://temaprocess.com/wp-content/uploads/2019/12/Tema-wide-dust-recovery-hood-captures-airborne-particles-and-returns-it-to-the-process-video.png)