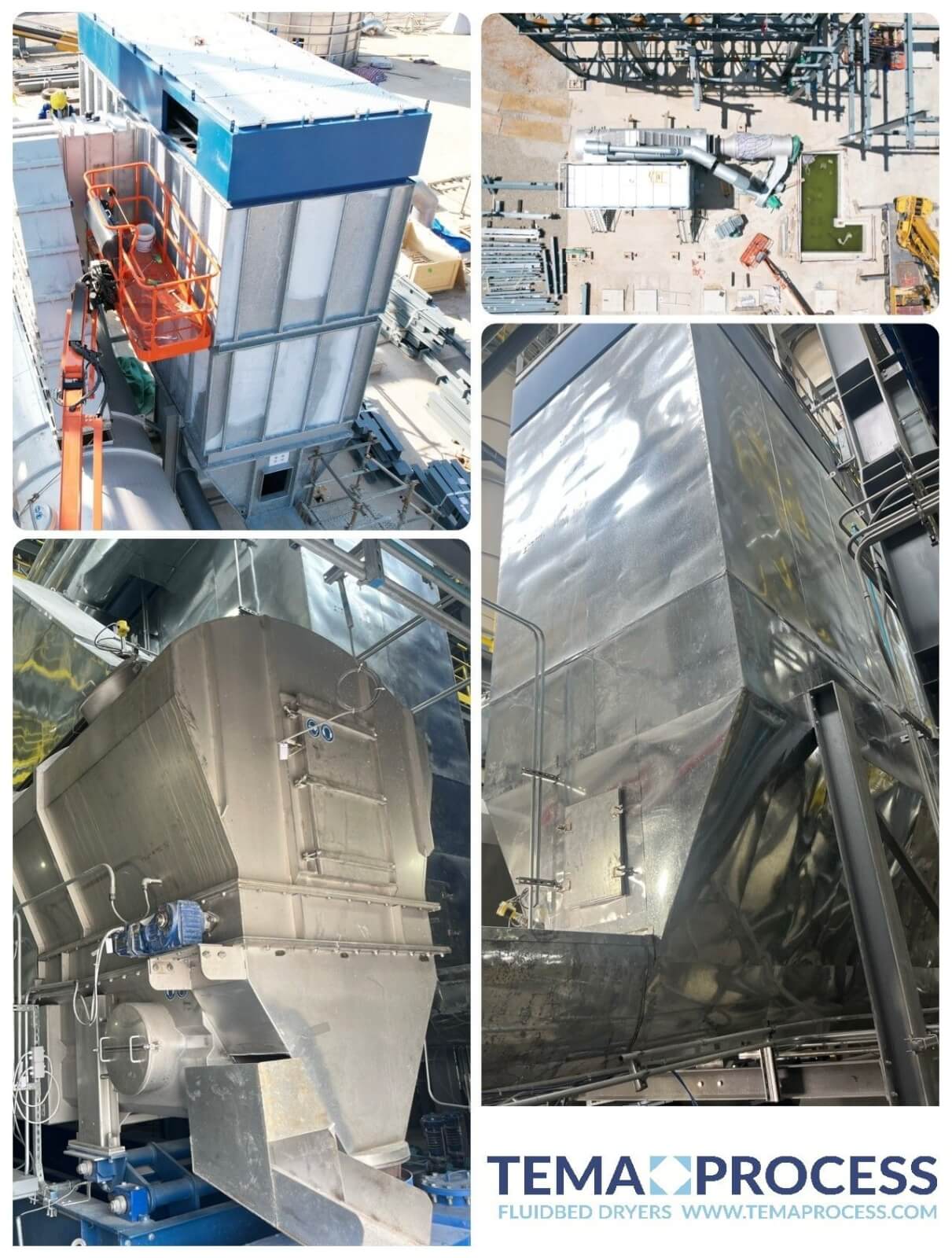

Erection and Commissioning of a Fluid Bed Dryer/Cooler for Minerals.

Successfully completed the erection and commissioning of a fluid bed dryer/cooler for mineral processing. The scope included mechanical installation, electrical and instrumentation works, and comprehensive pre-commissioning activities. Following installation, dry commissioning was carried out to verify airflow, temperature control, and safety systems. Operational commissioning with mineral material allowed optimisation of process parameters to achieve stable fluidisation and reliable drying and cooling performance. The project was [...]

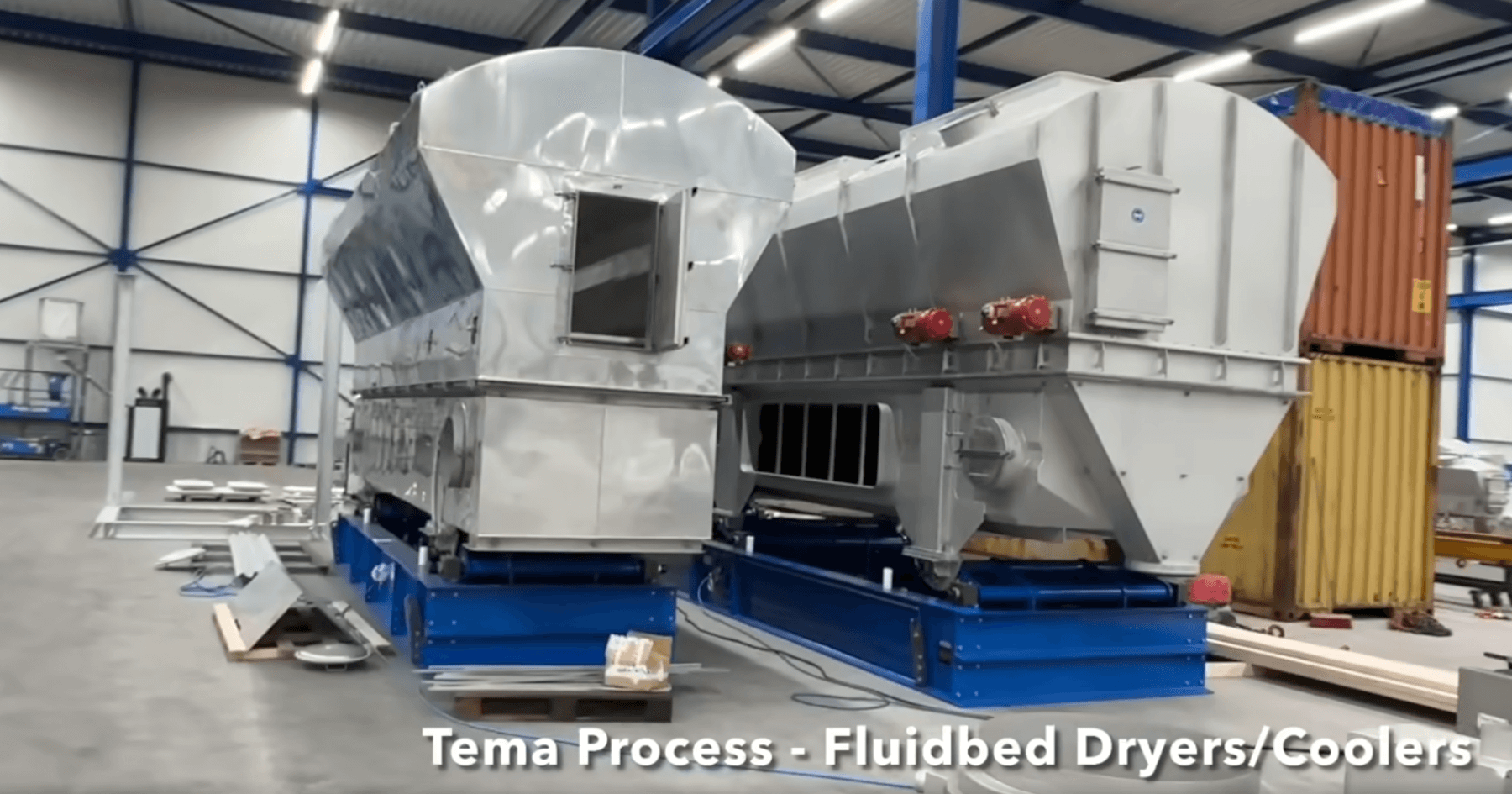

Six Tema Process fluid bed dryers/coolers ready for shipment

Another milestone achieved: six Tema Process fluid bed dryers/coolers completed and ready for shipment to our worldwide clients in the food, chemical, waste, and mineral industries. […]

Energy Savings in a Tema Sand Dryer/Cooler System

Optimizing industrial drying and cooling processes can result in significant energy savings. One effective method is recirculating the exhaust air from the cooling section back to the dryer’s air inlet. - The cooler exhaust air, typically at 50–60 °C, still contains valuable thermal energy. - By reusing this air, energy savings of 10–15% can be achieved. - This reduces the need for fresh heated air and [...]

On-Site Fluidized Bed Test Dryers for Complex Processes

For certain products, the drying or cooling process is too complex to be accurately tested at the Tema Process laboratory. This may be due to specific upstream process conditions, sensitive material behavior, large particle size distributions, safety requirements, or integration with existing plant equipment. For these applications, Tema Process supplies laboratory and pilot-scale fluidized bed test dryers that are installed and operated at the customer’s [...]

Erection & Commissioning | TEMA Process Bio-Coal Belt Dryer

We successfully completed the erection and commissioning of a TEMA Process bio-coal belt dryer. From foundation checks and mechanical installation to belt alignment, air-handling systems, and safety integration — every step was executed with a strong focus on safety, quality, and performance. The multi-zone belt dryer is engineered for energy-efficient and uniform drying of bio-coal, offering precise temperature control, optimized airflow distribution, and a low-dust [...]

Potash Drying with TEMA Process Fluid Bed Dryers

Potash is a potassium-rich, water-soluble salt, and around 95% of global production is used as fertilizer. The most common form is potassium chloride (KCl), but potash fertilizers may also include K₂CO₃, K₂SO₄, or KNO₃. These nutrients play a vital role in agriculture—improving water retention, crop yields, and even the taste and nutritional value of many plants. After potash is mined, it must be processed into [...]

Plant Protein Processing Technology for Animal Nutrition

At TEMA Process, we support the growing demand for high-quality plant proteins in the animal feed industry. TEMA Process is proud to be part of that evolution. Our integrated systems for soy and pulses combine: - Pressure steam cookers for safe, uniform conditioning - Fluid bed dryers for precise, energy-efficient drying & cooling Together, these technologies convert raw soy and pulses into high-value protein ingredients [...]

Why are minerals dried in a Tema Process fluid bed dryer?

For minerals like sand, gypsum, talc, salts, clays and limestone, a Tema Process fluid bed dryer offers industry-leading performance and product quality. - Uniform and consistent drying Our fluidization technology ensures perfect heat transfer and stable final moisture — no hot spots, no overdrying. - High energy efficiency Tema Process systems are designed with optimized airflow, low pressure drop and optional heat recovery, delivering one [...]

Processing Technologies for Breadcrumbs

Breadcrumbs are produced in a continuous, controlled process to ensure uniform color, texture, and particle size. A specially formulated dough—yeast-fermented or non-yeasted for lighter crumbs like Panko—is mixed from wheat flour, water, salt, and optional ingredients. The dough is formed into sheets or blocks with rollers or extruders and baked in a tunnel oven, where moisture is reduced and structure and color are developed. After [...]

TEMA’s fluid bed dryers for LiOH

For lithium hydroxide monohydrate, it is essential to dry it at a temperature and humidity that avoids removing the water of crystallization, which would turn it into anhydrous LiOH or cause it to react with carbon dioxide. To achieve dry lithium hydroxide monohydrate, the wet salt needs to be dried, keeping the monohydrate stage, and without removing crystalline water. The drying system uses a CO2 [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety