Tema Process on Fluid Bed Drying Solutions for Recovered Carbon Black

Our colleague Koen Egberts shared how fluid bed dryers boost drying performance, energy efficiency, and consistency in rCB production — a critical step in sustainable carbon black recovery. Koen Egberts Explains how Fluid Bed Dryers Improve rCB Drying Efficiency Tema Process were attending and exhibiting at the conference to present their Fluid Bed Dryer Solutions. “Events like this are key to staying connected with market [...]

Chemicals commonly dried in fluid bed dryers

Fluid bed dryers are widely used in the chemical industry to dry powders, crystals and granules with precise moisture control and uniform product quality. Typical applications include: – Inorganic chemicals – ammonium sulfate, ammonium nitrate, sodium salts, potassium salts, copper sulphate, lithium carbonate, lithium hydroxide – Organic chemicals – organic acids, chemical intermediates, detergent ingredients – Plastics, polymers & resins – plastic granules, polymer powders, [...]

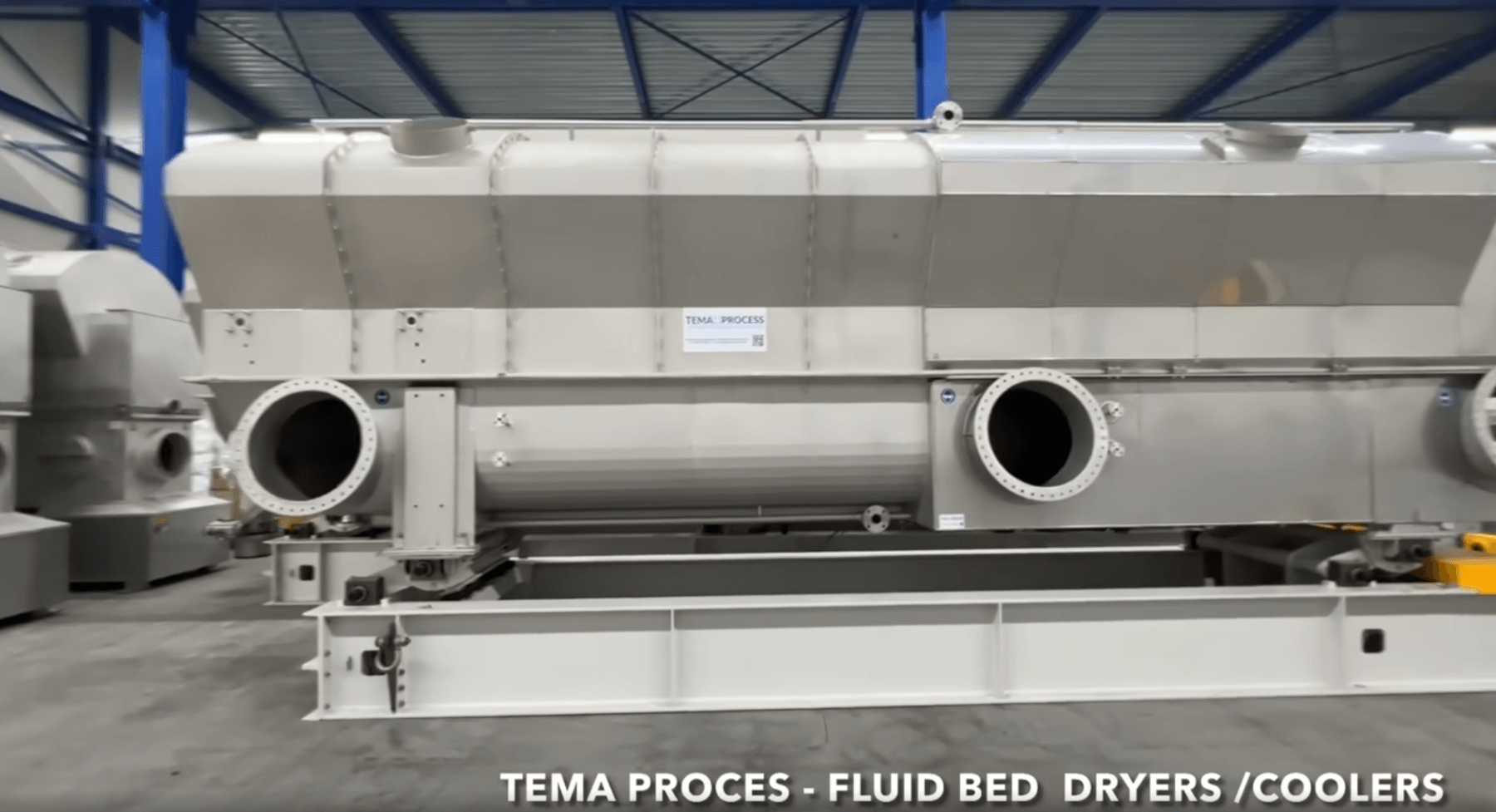

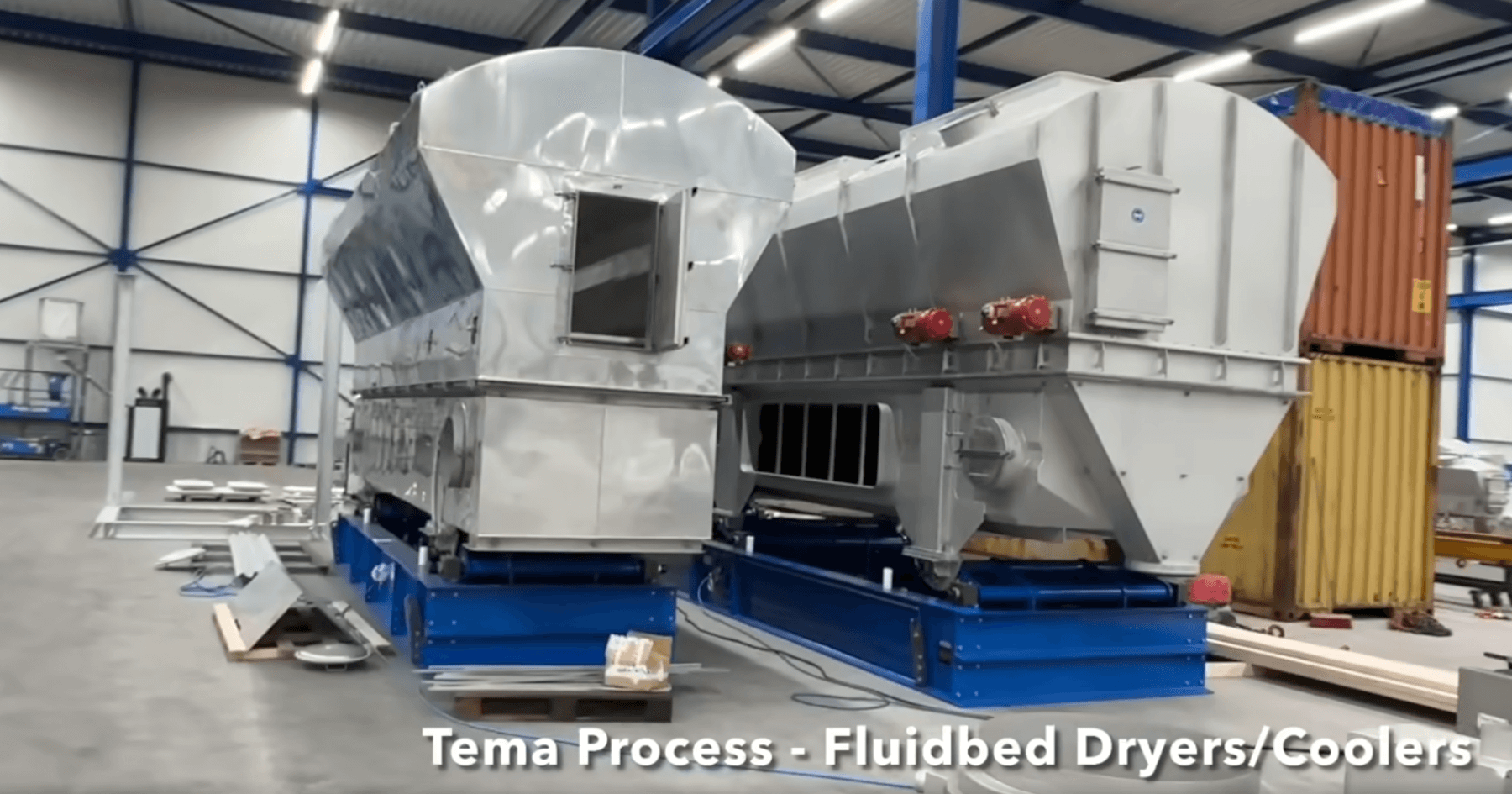

Six Tema Process fluid bed dryers/coolers ready for shipment

Another milestone achieved: six Tema Process fluid bed dryers/coolers completed and ready for shipment to our worldwide clients in the food, chemical, waste, and mineral industries. […]

Processing Technologies for Breadcrumbs

Breadcrumbs are produced in a continuous, controlled process to ensure uniform color, texture, and particle size. A specially formulated dough—yeast-fermented or non-yeasted for lighter crumbs like Panko—is mixed from wheat flour, water, salt, and optional ingredients. The dough is formed into sheets or blocks with rollers or extruders and baked in a tunnel oven, where moisture is reduced and structure and color are developed. After [...]

BIC Protein Extruded

Extruded TVP […]

Tema Process Gelatin Dryer

Product video of the Tema Process Gelatin Dryer […]

Smart Energy Control – Optimized by AI | Built by TEMA

Smart Energy Control – Optimized by AI | Built by TEMAOur Sales Manager Daniel Verbaan explains how TEMA Process stands out in building high-end mineral dryers. With our hybrid intelligence control software, the system automatically enables the use of the most efficient and sustainable heat source during the drying process, taking into account availability, costs, and carbon targets. Combined with our smart engineering solutions, this [...]

Smart Moisture Control: Predictive Drying Performance

Smart Moisture Control: Predictive Drying PerformanceMoisture content is one of the most critical parameters in mineral drying. Whether processing silica sand, feldspar, limestone, or other minerals, achieving a stable and precise final moisture level directly impacts product quality, energy consumption, and operational efficiency. TEMA Process Smart Moisture Control combines our proven dual-sensor logic with AI foresight. It continuously analyzes product feed rate, inbound moisture, and [...]

Successfully commissioned gelatin dryer

Another successfully commissioned gelatin dryerCurious about the many possibilities? We’re happy to support you with our expertise. […]

Fluidized Bed Dryer for Sand

A Tema fluidized bed dryer (also known as a fluid bed dryer) is commonly used in industries for drying particulate materials like sand due to its efficiency and uniformity. Here are the main advantages of using a fluidized bed dryer specifically for drying sand: Advantages of Fluidized Bed Dryer for Sand 1. Efficient Heat and Mass Transfer The fluidization of sand particles allows maximum contact [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety