Belt dryer and air dehumidifying solutions for the gelatin industry

We’re excited to share our new animation showcasing Tema Process’s belt dryer and air dehumidifying solutions for the gelatin industry. Discover how our advanced technology ensures efficient drying and precise humidity control, crucial for maintaining the highest quality standards in gelatin production. ???? Watch the Video to see: – How our belt dryers provide gentle and consistent drying. – The role of our air dehumidifiers [...]

Tema Fluidbed dryers in the Dry Mortar industry

Remix Dry Mortar […]

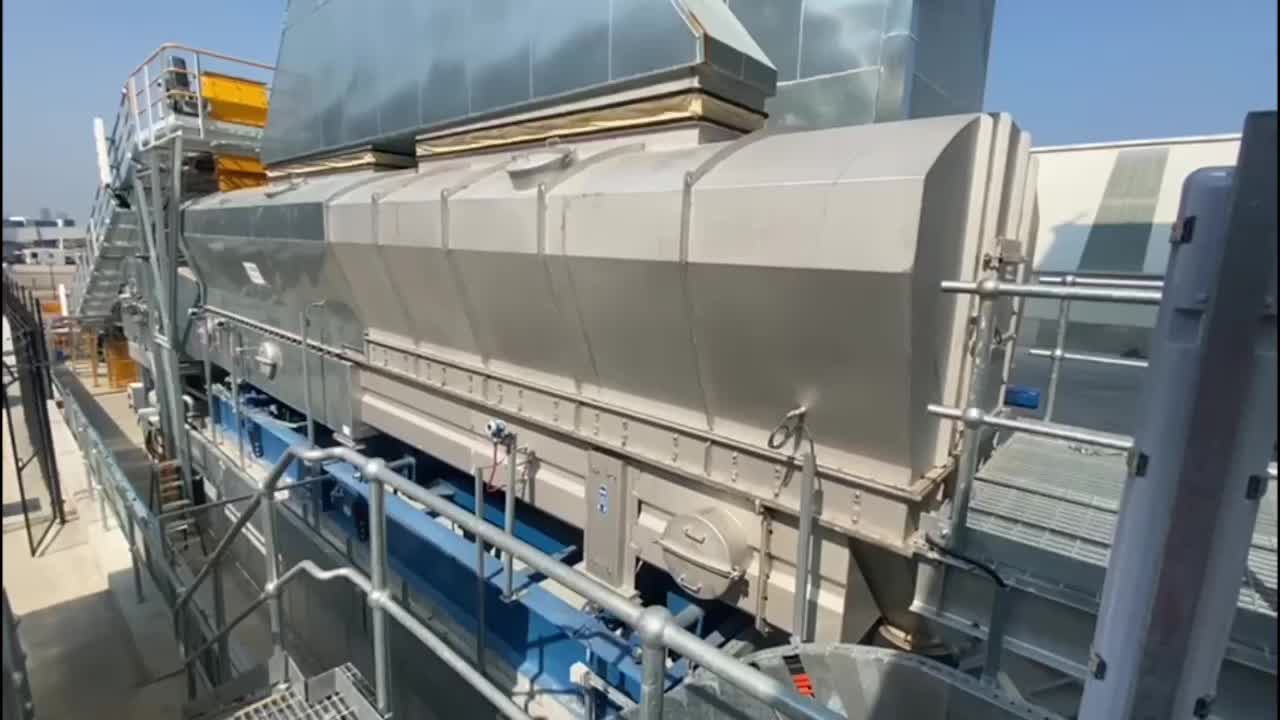

Tema Process Sodium Chloride Dryer/Cooler

Video of Sasko Algeria Salt NaCl Drying/Cooling […]

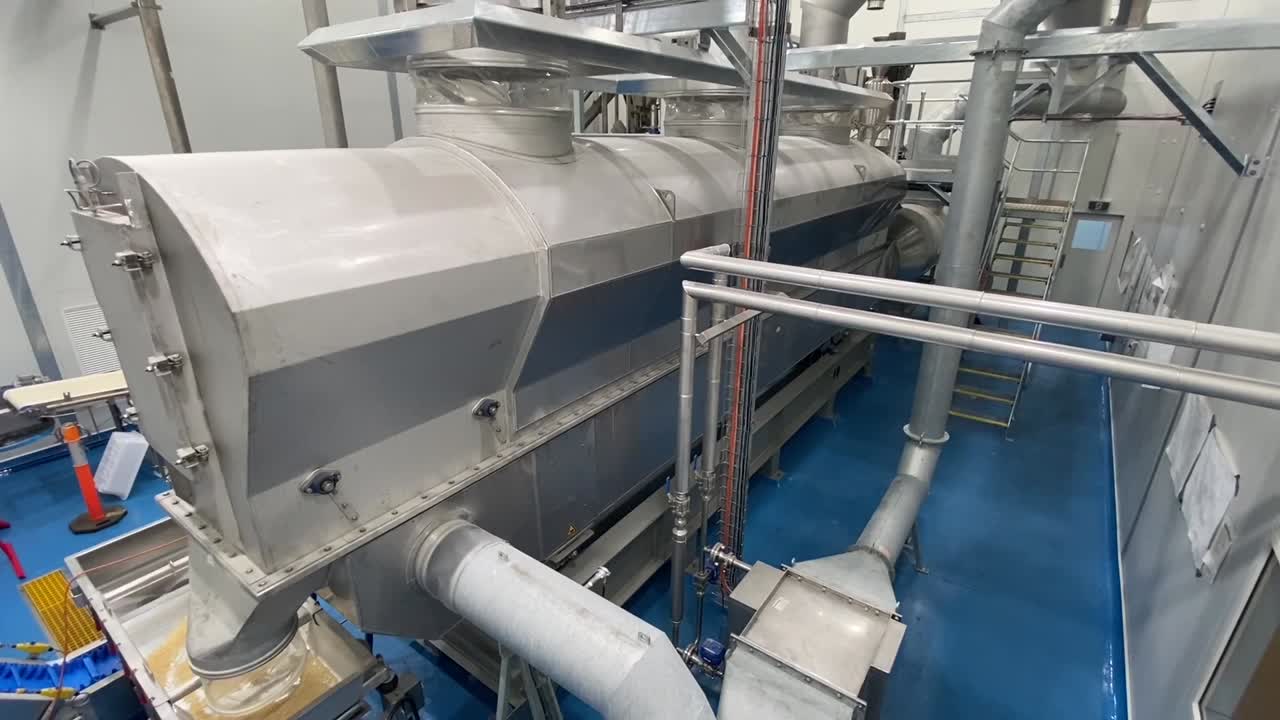

Meatless Fluidbed Drying

Meatless produces unique plant-based textured products for the vegan, vegetarian, meat and fish industry. Meatless products are clean in taste, produced from local crops, using whole foods. It’s made using gentle natural processes and it’s the most sustainable way to produce textured vegetable products. […]

Assembly of a Tema Fluidbed dryer/cooler

Video about the assembly of a Tema Fluidbed dryer/cooler. […]

Containerized Fluid Bed dryer/cooler

Video of a Containerized Fluid Bed dryer/cooler. […]

Special transport

Video about a special transport of a stainless steel filter for a Fluidbed dryer/cooler system. […]

Tema Fluid Bed Dryers: Factory Acceptance Test (FAT)

Tema Fluid Bed Dryers. A Factory Acceptance Test (FAT) is a formal test and inspection work process that is performed at our Tema process workshop and is done when the system is fully fabricated and assembled prior to the shipping. The FAT is to check the functionality and capabilities of the equipment. […]

Dryers for sand

Drying sand Typically, sand is mined, washed and screened and stored in piles with various grades. The sand needs to be dried to the required moisture content before it can be sold or further processed. Silica sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules. Silica sand is the primary component of all types [...]

Drying Processes for Black Soldier Fly Larvae

Optimizing Drying Processes for Black Soldier Fly Larvae Using Fluidized Bed Dryers with Plug Flow. Introduction. Black Soldier Fly (BSF) larvae have gained significant attention in recent years due to their versatile applications in waste management, animal feed production, and even human consumption. One critical aspect of utilizing BSF larvae is the drying process, which plays a crucial role in preserving their nutritional value and [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety