Drying Technology – Black soldier fly larvae (BSFL)

Black soldier fly larvae (BSFL) are used to compost waste or convert the waste into animal feed. BS jFly larvae are among the most efficient animals at converting biomass into feed. Low temperature drying prevents the loss of valuable nutrients and baking or burning of the larvae. […]

Fluid Bed Dryer for Sand

Sand drying: a fluid bed dryer processes granular, free-flowing materials include sand, minerals, clays, etc. In a fluid bed, the material being dried is suspended and completely surrounded by the drying air or gas, causing that material to behave like a fluid. Besides keeping the material in a seemingly liquid state, the gas stream is the media for heat and mass exchange. As a result [...]

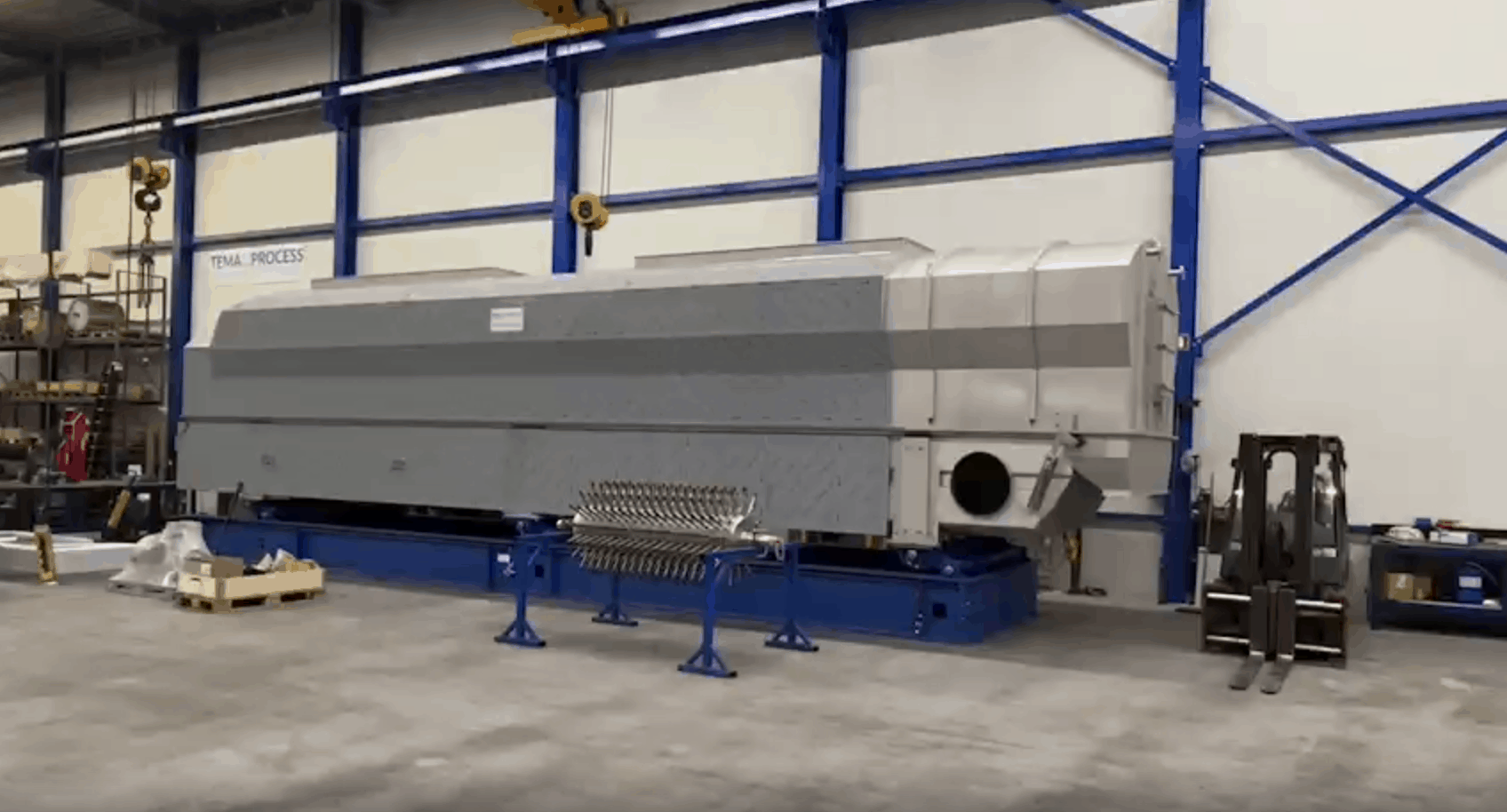

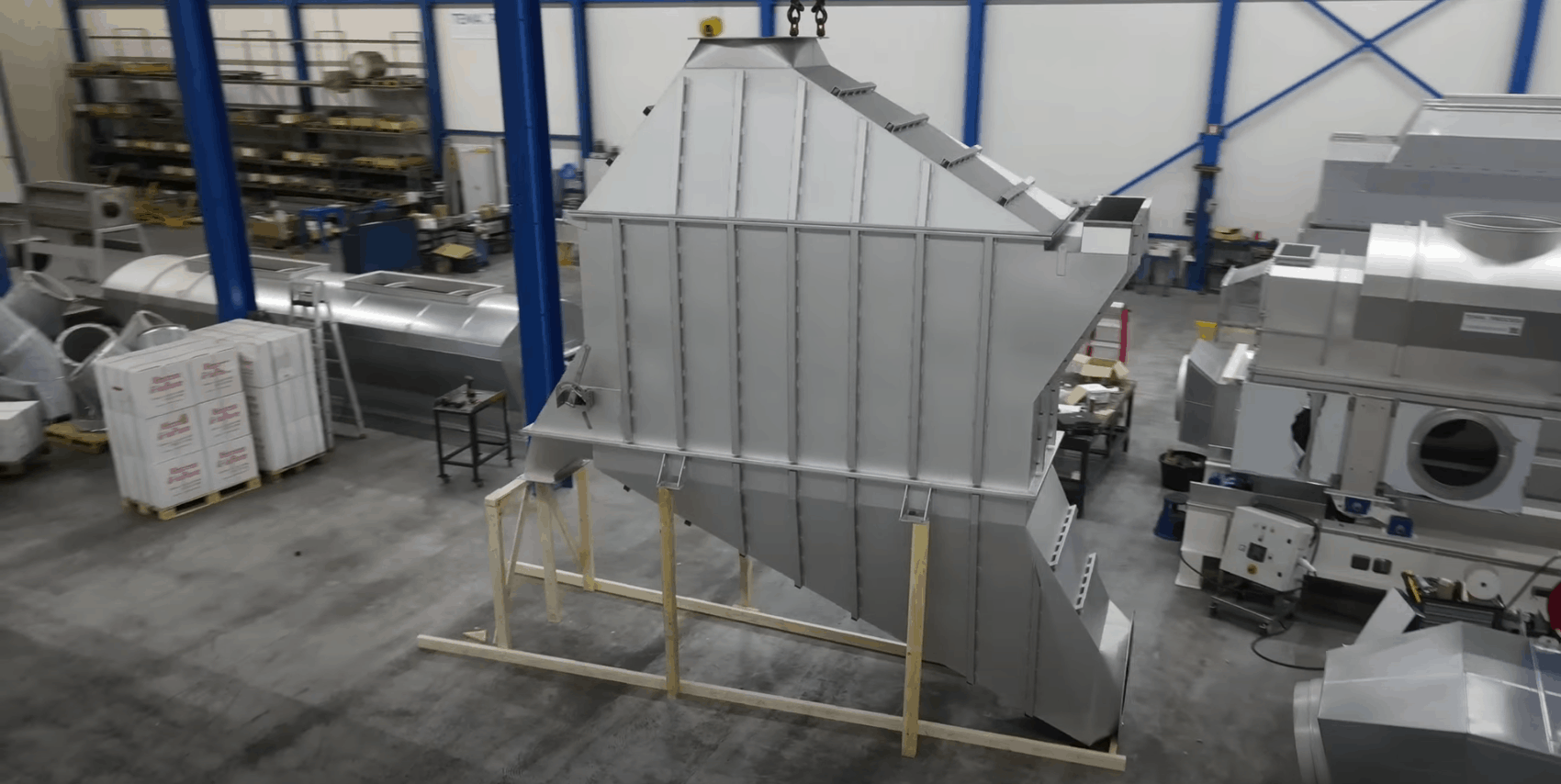

Dryers ready for Shipment!

Thermal drying is a process found in almost all industries. There are various choices of fluidized bed dryers available. Particles/powders are classified into major groups according to their characteristics when exposed to fluidizing gas stream, this is used as the main criteria for selection of Fluid Bed Dryer/Cooler for a particular application. An efficient drying technology: desired quality at minimum cost, low carbon footprint and [...]

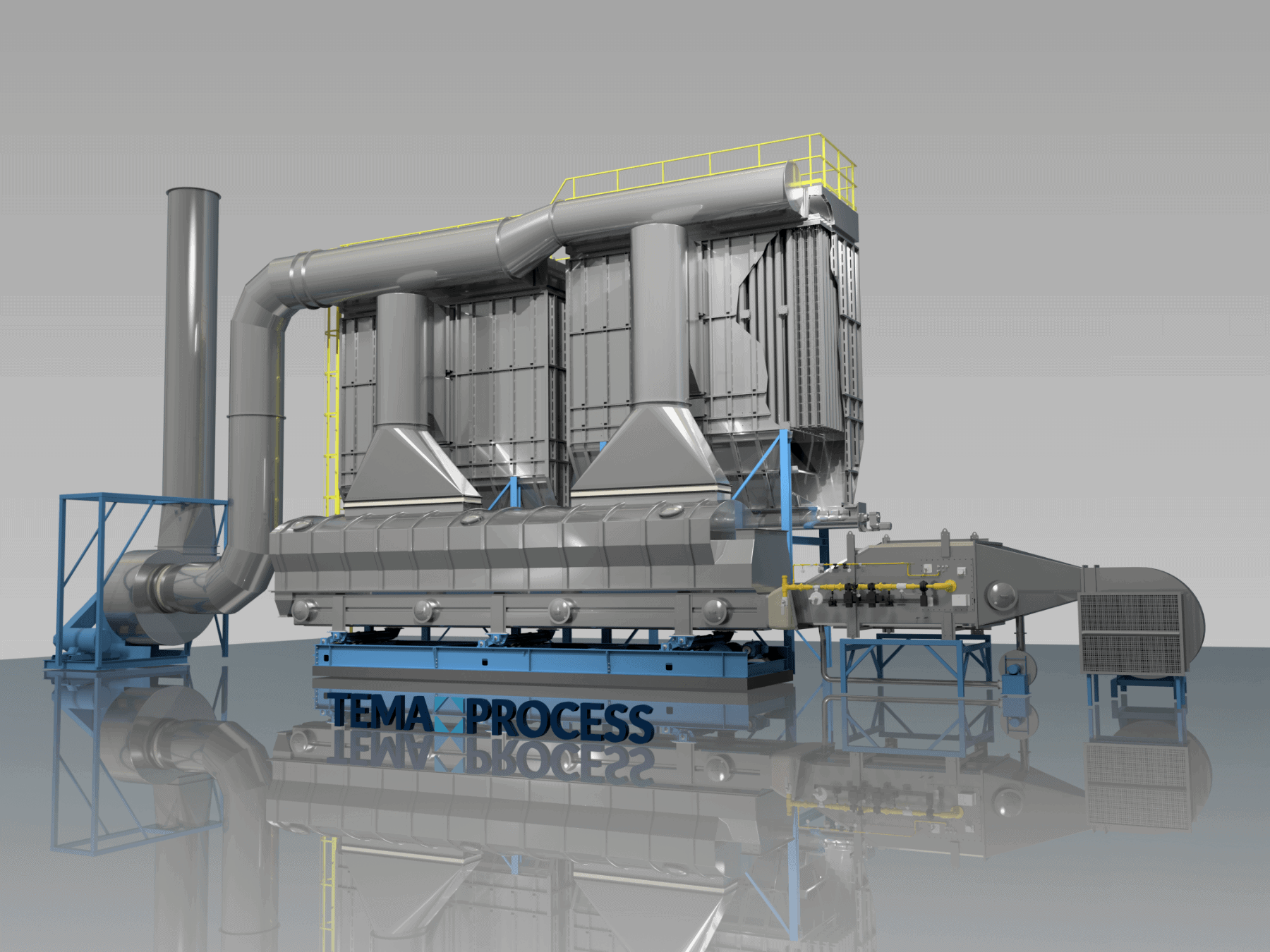

Thermal Treatment Solutions

Fluid Bed Dryers for : Copper Sulfate (CuSO4.5H2O), Bread crumb, Sand & aggregate, Potassium Chloride KCL, Sodium Chloride NaCl, Digestate, Larvae BSF, SLS needles, PE PP Pellets, Lithium hydroxide monohydrate, Lithium Carbonate, Carbon black granules, Granulated fine clay + sand, Ammonium Sulphate (NH4)2.S04, Calcium Nitrate granules (fertilizer), Talc, Sodium sulphate Na2SO4, Lithium hydroxide monohydrate, Polystyrene granules, Wet fibre residue oat, Fungicides / Insecticides, Mono Ammonium [...]

ThermoSeed: The cleanest seed in the world Vihervakka Lantmannen

Globally there is an increasing demand for sustainable crop production processes. ThermoSeed offers an innovative, highly efficient and environmental friendly seed treatment technology with great added value to seed processors and farmers. ThermoSeed was developed in Sweden in the nineties and has undergone rigorous testing in a wide range of crops under various climatic conditions worldwide with remarkable and consistent results. Nowadays 60.000 tons of [...]

Tema Process: Mineral drying

Mineral drying: sand, talc, limestone, gravel, clay etc. Tema Process Fluid Bed Dryers. […]

Static (non-shaking) fluidised bed

Static (non-shaking) fluidised bed or fluid bed (dryers and coolers) are used on free flowing fluidised bulk materials that have a narrow particle size distribution. The static fluid bed remains stationary during operation. Static fluid bed dryers can be continuous or batch operation and may be round or rectangular. The other type of fluid bed dryer is a shaking fluid bed dryer or cooler, where the body [...]

Installing ThermoSeed equipment at Vihervakka Finland

Seed treatment without chemicals: ThermoSeed uses the innovative thermal disinfection tool which applies hot humid air to the seeds as a form of steam pasteurization. […]

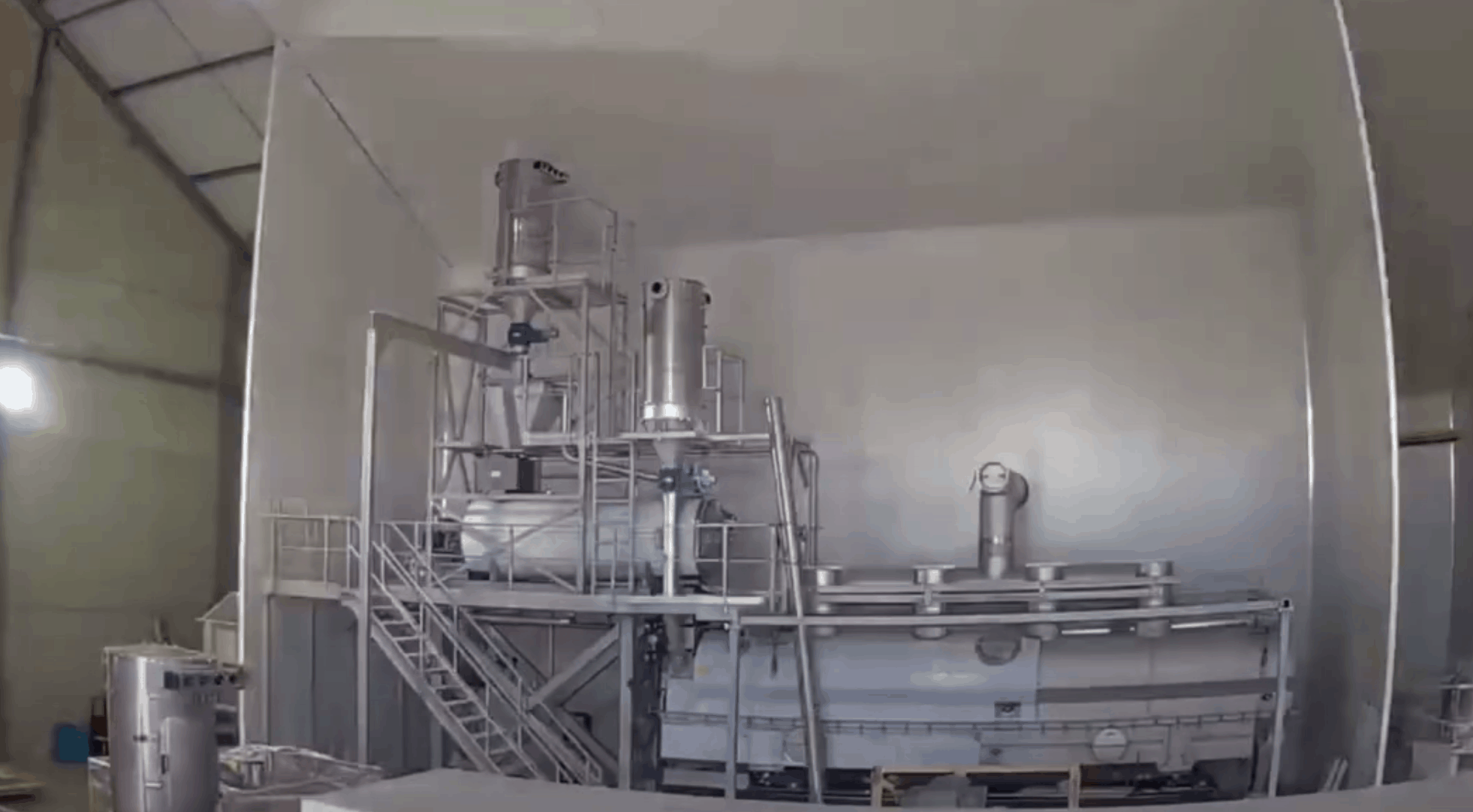

Time lapse: Tema steriliser

Erection of a Tema Process Steam steriliser for spices, seed and herbs. […]

SiebTechnik Tema cooperate

SiebTechnik Tema cooperate video […]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety