Fluid bed dryers & coolers

How does a fluid bed dryer work?

A continuous fluid-bed system is a machine in which a continuous flow of “wet” powder, granular or flakes material is conveyed over a perforated bed. Hot drying air is blown through the holes of a perforated plate. The wet solids are lifted from the bottom and causes the solids to behave as a fluid. The air velocity is adjusted to keep the moving layer of material fluidized.

Conveying of the product is achieved by means of a low-frequency, high amplitude shaker mechanism. The “Shaking” motion plug flow of the Tema fluid bed, allows first-in, first-out drying of products and well-mixed fluidization, which covers the entire spectrum and is able to accurately control the spread of residence time.

Advantages of continuous fluid-bed dryer system technology

Advantages of continuous fluid-bed dryer system technology

TEMA Process is specialized in the design and manufacture of Fluid Bed Systems for a variety of industries. Our expertise extends to drying, cooling, roasting, torrefaction, puffing, blanching, stripping, and the sterilization and pasteurization of spices and herbs. We offer both continuous and batch fluid bed systems, tailored to meet specific industry requirements. These systems are particularly well-suited for handling minerals, chemicals, food, feed, and biomass. TEMA Process’s technology is versatile, supporting industries from pharmaceuticals to food production, ensuring product integrity in batch processes and efficiency in continuous operations. Our fluid beds are customizable, with options like static or dynamic configurations and submerged heat exchangers, showcasing our commitment to innovation and client-specific solutions.

Types of Fluid bed dryers

Fluid bed units

A fluid bed is an effective unit to thermally treat powders, crystalline products, pelletized or extruded materials. High heat and mass transfer are obtained as a result of the intimate contact between fluidizing air and product.

Shaking fluid bed

units for continuous operation and suitable for sticky materials with a wide particle size distribution. The shaking motion improves the fluidization and transport of any material within the fluid bed. Drying gas temperature up to 750 °C and product temperatures up to 400 °C are achieved

Static fluid bed

units in continuous and batch type for more uniform materials that do not tend to agglomerate. It is possible to install submerged heat exchangers in a deep static bed. With submerged heat exchangers energy input is both from the fluidizing air as well as from the heat exchangers reducing the size of the equipment and limiting the exhaust air volume.

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety

Industries

Tema Process offers solutions suitable for a broad number of industries

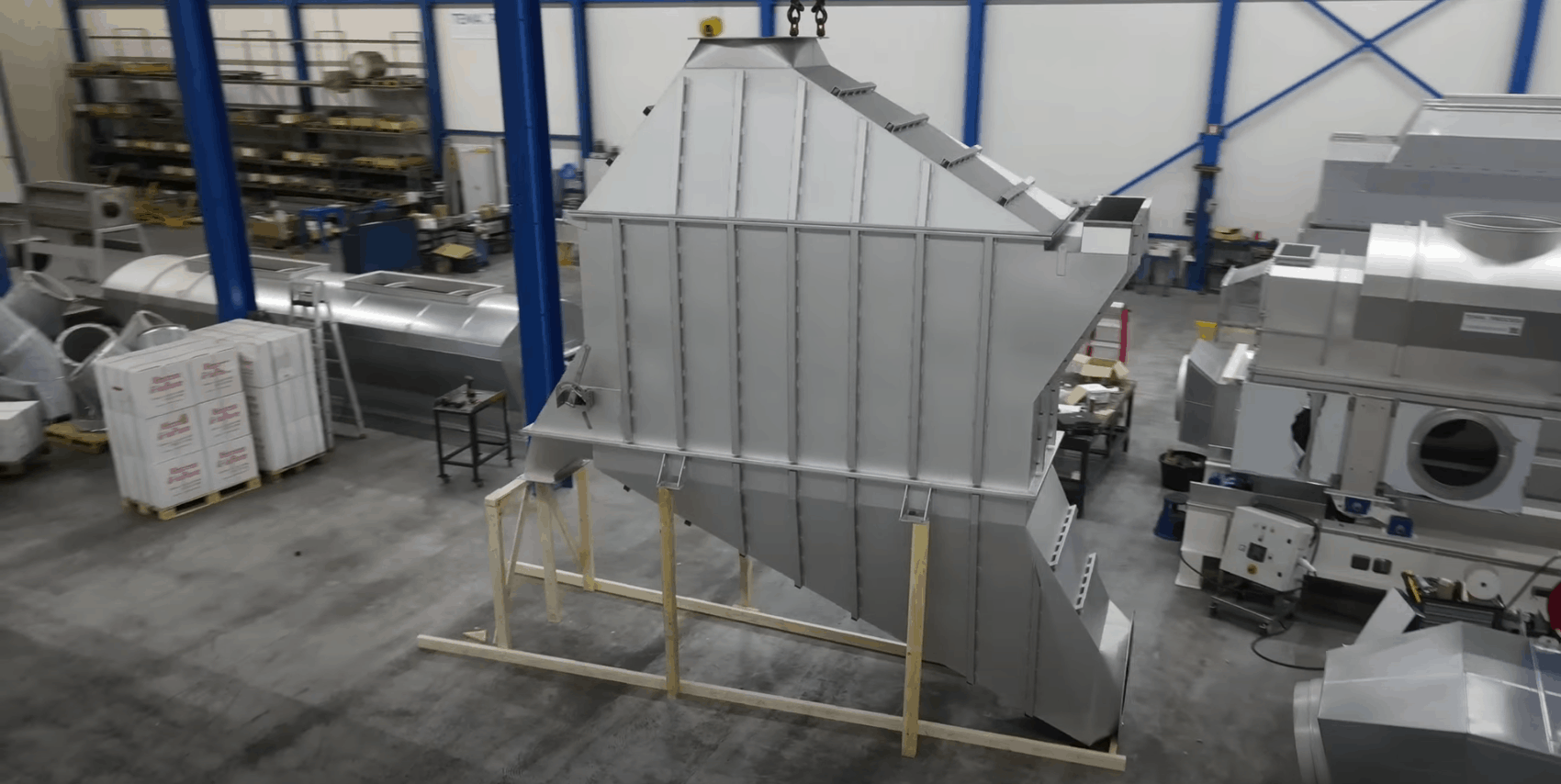

TEMA Process: Custom Fluid Bed Dryer Manufacturing

To prepare for further growth, TEMA Process BV in has moved to its new engineering ( 1800 m2) and production ( 8000 m2) facility in the Netherlands. The new facility was built under management of TEMA Process BV and is totally fit for manufacturing of fluid bed dryers, coolers and associated equipment.

Expertise in Fluidized Bed Dryer Design and Engineering

TEMA Process specializes in the design, engineering, testing, and installation of custom fluid bed dryers for a variety of industrial applications. As a leading fluid bed dryer manufacturer, we focus on delivering high-quality, custom-made drying solutions tailored to the specific needs of your factory.

Precision Engineering for Optimal Performance

Our fluidized bed dryers are engineered with precision, ensuring that each machine meets the specific requirements of your production process. Our team of experienced engineers collaborates closely with you to develop dryers that integrate seamlessly into your existing systems, enhancing efficiency and productivity.

Comprehensive Testing and Installation

Every fluid bed dryer from TEMA Process undergoes rigorous testing to guarantee performance and durability. Our commitment to quality extends from the design stage through to the final installation in your facility, ensuring that our machines operate optimally within your production environment.

Reliable Solutions for Your Drying Needs

As your fluid bed dryer manufacturer, TEMA Process is dedicated to providing solutions that enhance the productivity and efficiency of your operations. Our custom-engineered fluidized bed dryers are designed to meet the unique challenges of your factory, delivering reliable and effective drying performance.

Want more info? download our technical sheet

Gain a comprehensive understanding of our diverse product range through our detailed technical sheets. Available in multiple languages, these sheets offer key insights to inform your decisions.

Enhance your knowledge with images included in our sheets that help elucidate the processes and their applications, making it easier for you to visualize and grasp the practical aspects of our products.