Successful commissioning of our new gelatin belt dryer

We are excited to announce the successful commissioning of our new gelatin belt dryer. A Tema gelatin dryer is designed to remove moisture from gelatin [...]

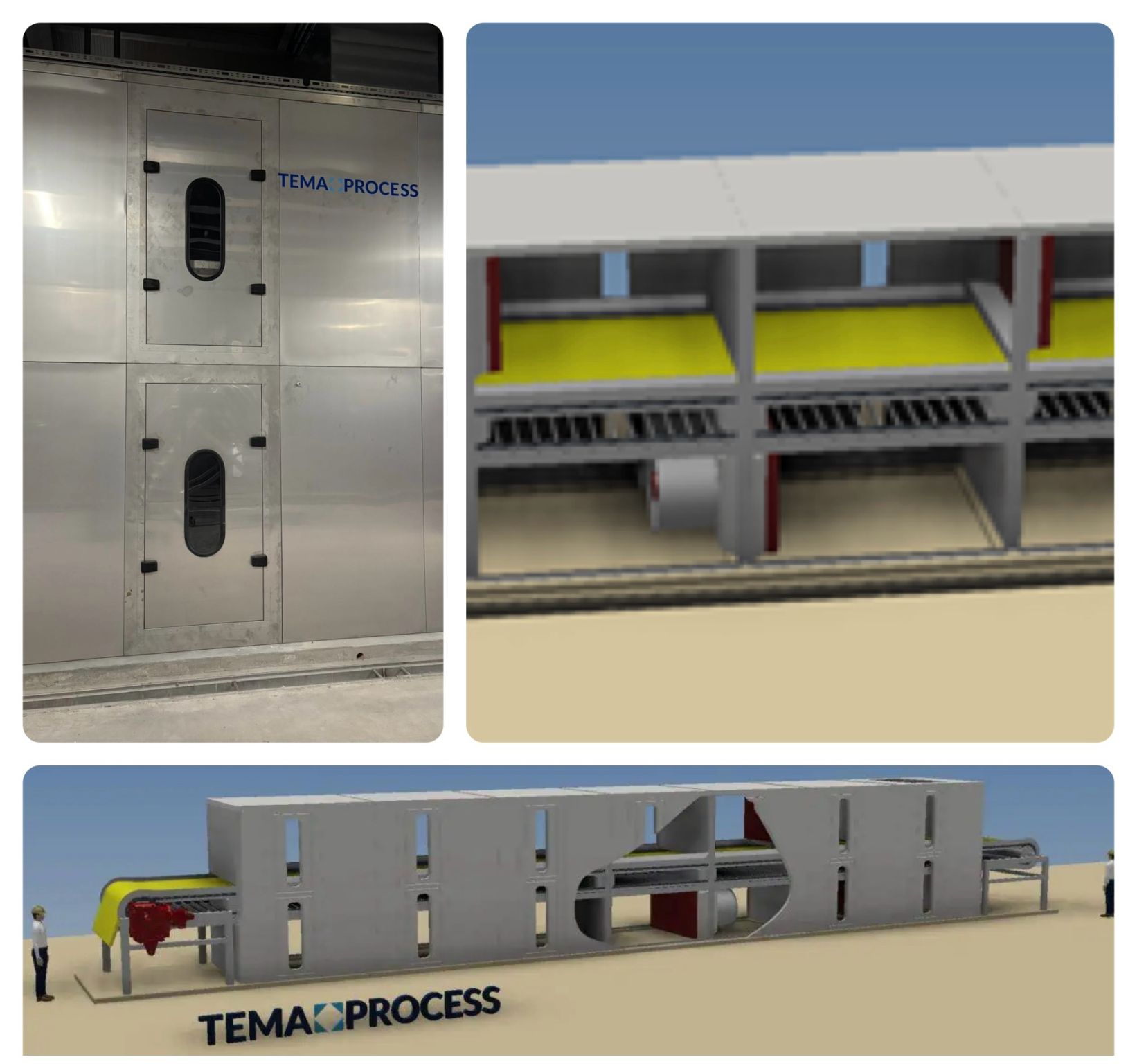

Transport of TEMA Breadcrumb dryer

Breadcrumb, rusk or Japanese processing lines: Breading’s typically contain seasonings and are applied as coatings to fried or baked foods to achieve certain textures, colours, [...]

Drying Chemicals

Tema Process Fluidized bed systems are commonly used for drying and cooling a wide range of chemicals, powders, and granules. The suitability of a material [...]

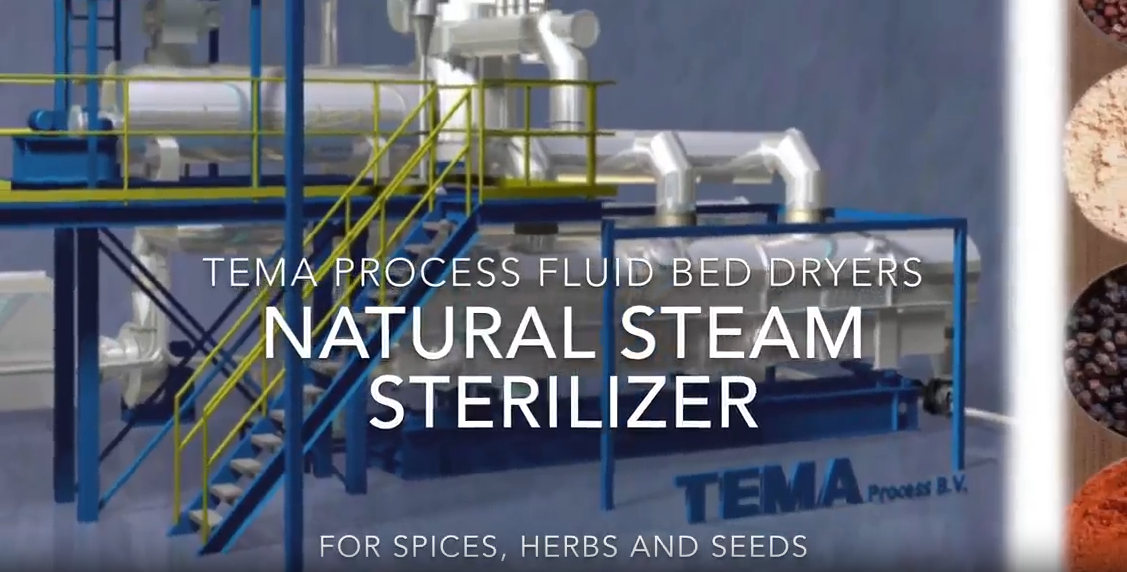

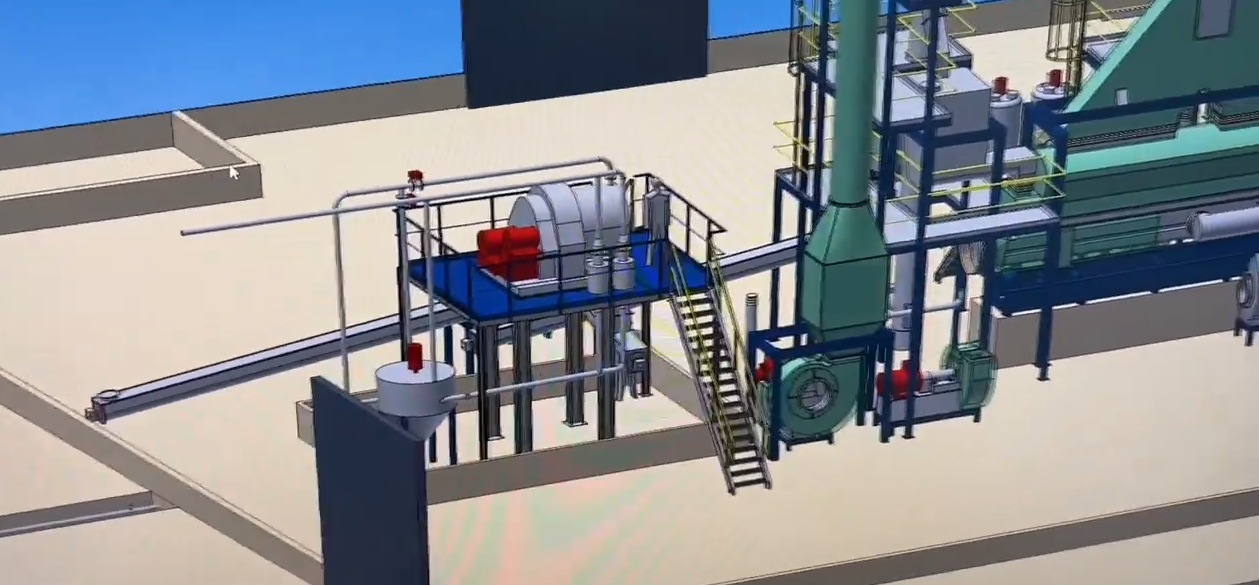

Steam Sterilization vs. EtO for Spices: The Safer Choice

Steam Sterilization vs. EtO for Spices: The Safer Choice Across the globe, food producers and regulators are moving away from ethylene oxide (EtO) due to [...]

Multi-temperature zones in a fluid bed dryer

Multi-temperature zones in a Tema Process fluid bed dryer are used to optimize the drying process by providing better control over moisture removal, product quality, [...]

The proces of drying and washing sea salt

The sea salt washing and drying process is essential to produce clean, high-quality salt suitable for consumption and industrial use. Here’s a general overview of [...]

Fluidized bed drying; one of the well-known and versatile methods

Out of various drying techniques, fluidized bed drying is one of the well-known and versatile methods. It is known for its uniform drying and high [...]

Sodium sulfate Na2SO4 dryer and Bread crumb dryer ready for transport

Tema Fluid Bed Systems for drying of minerals, chemicals, food, feed, biomass, etc. The TEMA Fluid Bed can be applied not only for drying, but also [...]

Transport of a Sand dryer with energy recovery

High temperature drying at up to 600°C: This results in greater evaporation per square metre of bed without an increase in air volume, reduces the [...]

Sub-Fluid Bed Dryer for Black Soldier Fly Larvae Drying

Sub-Fluid Bed Dryer for Black Soldier Fly (BSF) Larvae Drying: An Efficient Solution for Insect Protein Processing The drying of Black Soldier Fly (BSF) larvae [...]

Sand dryer with heat recovery system

Erection and commissioning of a Tema Process sand dryer with heat recovery system. Sand is often dried for several practical reasons across different industries and [...]

Gelatin belt dryer with dehumidifier

The gelatin belt dryer with a dehumidifier by TEMA Process is regarded as one of the best systems for gelatin drying due to its advanced [...]

TEMA Process Partners with Outokumpu for a Greener Future

We're excited to share that TEMA Process is joining forces with the globally recognized stainless steel leader, Outokumpu, to implement a state-of-the-art industrial belt dryer [...]

Enhancing Waste-to-Energy Efficiency: The Role of Tema Process Digestate Dryers

Enhancing Waste-to-Energy Efficiency: The Role of Tema Process Digestate Dryers In the realm of renewable energy and sustainable waste management, anaerobic digestion (AD) is a [...]

Fluid Bed Dryer suited for drying kaolinite

Drying: China clay, also known as Kaolinite or Kaolin (chemical formula Al₂(OH)₄Si₂O₅), is one of the most common and versatile minerals in industrial applications. Importance [...]

Pepper Sterilization

A Tema Process steam sterilizing system is widely used for sterilizing pepper due to its efficiency, reliability, and ability to preserve the quality of the [...]

Fluid bed dryer for TVP

Textured or texturized vegetable protein (TVP), also known as textured soy protein (TSP), soy meat, or soya chunks, is a defatted soy flour product that [...]

Tema Process Condenser Scrubbers

Scrubber ready for transport. Tema Process Condenser Scrubbers are designed to condense, absorb, cool and scrub large volume of exhaust gases. These scrubbers are used [...]

Tema Process SLS Shaking Fluidbed Coolers

Tema Process SLS Shaking Fluidbed Coolers ready for transport: Sodium Lauryl Sulfate (SLS) Needle, also known as Sodium Dodecyl Sulfate (SDS), is an anionic surfactant [...]

LiOH, Li2CO3 and Na2SO4 dryers ready for transport

Lithium hydroxide (LiOH) enables the production of batteries for electric vehicles (EVs). Spodumene is a mineral consisting of lithium aluminium inosilicate, LiAl(SiO3)2, and is a [...]