Ventilation and Dehumidification in the meat industry

In the meat processing industry, maintaining an optimal environment is crucial to ensuring product quality, safety, and compliance with hygiene standards. TEMA Process specializes in advanced ventilation and dehumidification solutions designed to address the unique challenges faced by meat processing facilities. Our systems are engineered to provide precise control over airflow, temperature, and humidity, thus creating an environment that minimizes the risk of contamination and preserves the integrity of meat products.

High humidity levels in meat processing plants can lead to condensation on surfaces, including the product itself, which can foster the growth of microorganisms and compromise food safety. Traditional methods of temperature control are often insufficient to combat this issue, as they fail to adequately address the relative humidity within the processing environment. TEMA Process’s dehumidification technology tackles this problem head-on by ensuring that the dew point temperature remains below the temperature of any surface in the processing area, thereby preventing condensation and the subsequent risk of microbial growth.

Our solutions are not just about maintaining a dry environment; they are about creating a healthier, more efficient, and more sustainable operation. By incorporating our high-capacity dehumidifiers, meat processing plants can experience a range of benefits, including the elimination of undesired condensation on cold products, prevention of water dripping from ceilings, reduction in electrical failures, and the creation of a more comfortable and healthier climate for workers. Furthermore, our systems are energy efficient, helping to reduce operational costs while supporting your plant’s sustainability goals.

TEMA Process’s ventilation and dehumidification systems are custom-designed to meet the specific needs of each facility, taking into account factors such as ambient temperature, processing activities, and facility layout. Whether you are processing beef, pork, poultry, or any other type of meat, our systems ensure that your products move from cooling rooms to processing areas without the risk of condensation, thereby maintaining the highest standards of food safety and quality.

Embrace the future of meat processing with TEMA Process’s ventilation and dehumidification solutions. Our expertise and innovative technology provide the foundation for a safer, more efficient, and more sustainable meat processing industry.

Humidity, condensation and water are a serious risk

Both temperature and humidity levels inside a meat processing plant should be kept as constant as possible. It sounds simple, but the following characteristics continuously vary: outside weather conditions, rooms are periodically cleaned using water, personnel are at work and different products are processed. As most meat factories only control temperature, these aspects will all affect (raise) the relative humidity. A higher moisture level (RH) automatically means that the dew point temperature inside the room will rise, as room temperature remains constant at its regulated set point. At this dew point temperature water will condensate and becomes visible on products/parts which have a lower temperature.

So without good climate and humidity control, condensation (or “sweating”) can occur on cold meat products and food processing equipment. This moisture stimulates the growth and spread of microorganisms (such as mold, fungi and germs), even in areas considered clean. Meat products that need to be moved from cooling rooms to processing rooms are even much more susceptible to condensation because of their lower temperature. Dripping, fogging and icing are other potential moisture-related problems that often occur in the meat processing industry.

This means that a high dew point temperature has a big impact on the hygiene level and thus indirectly on the quality of your product. Proper environmental airflow, temperature and humidity control is the key to success. When meat is being processed, the Tema dehumidifier ensures that the room dew point temperature is always lower than the minimum product temperature. This way, moisture can never condense on the cold meat and the microbiological impact is minimized.

Dehumidifier – Energy savings

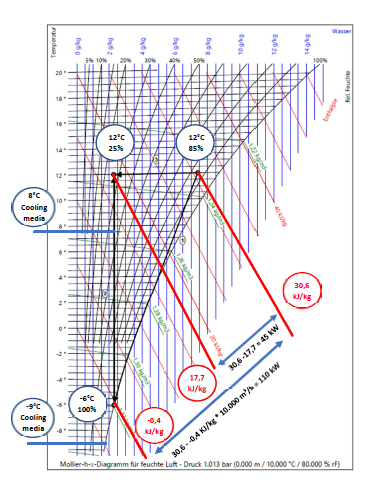

In comparison to traditional air conditioning systems (cooling and heating of air) a Tema Process dehumidifier will save 50 to 60% on cooling power consumptions. Beside these cooling power savings the required cooling media temperature will be considerably higher as this is primarily determined by the desired outlet air temperature. This temperature approach is

± 3 to 4°C under the desired air temperature.

Traditional air conditioning systems require a lower cooling media temperature as these have to cooldown the air until the desired dewpoint temperature. Meaning that the overall electrical usage of a Tema Process solution is considerably more energy efficient than evaporative air drying systems.

See example: 10.000 m3/h air is dehumidified from 12°C / 85% RH 8 g/kg to a supply condition of 12°C / 25% RH / 2 g/kg.

Quickly drying the whole factory after wet cleaning

At the end of the working day, when meat processing is ended the production rooms need to be cleaned. The whole factory is thoroughly rinsed and cleaned using hot water and detergents. After cleaning it is very important that the rooms are dried rapidly so that the next day production can start in a clean, cool and dry meat factory. The Tema Process ventilation and dehumidification solution will quickly master the water, humidity and consequently the micro-organisms level in your meat processing plant.

Our dehumidifier is the perfect airflow, temperature and humidity control solution and will bring the following benefits to your meat processing plant:

- No more undesired condensation on cold products

- No more undesired water dripping from ceilings

- Less electrical failures inside factory

- No more breeding ground and spread of micro-organisms

- The dehumidification process even kills bacteria

- Prevents odor nuisance

- Better (more comfortable and healthier) climate for workers

- No more draft of air

- Fresh air supplied to processing rooms

- Energy friendly ventilation solution

- Creates and controls under- or overpressure during day

- Factory is quickly dried after cleaning

This application has been successfully implemented in typical meat (Beef, pork and poultry) processing rooms like slicing areas, packaging rooms, sausage production areas, but also deboning and slaughter rooms.

Dehumidifying with a salt solution

The Tema Process air dehumidifiers have been developed for cooling, dehumidification and microbiological decontamination of industrial process air. These reliable systems ensure a constant humidity and constant air temperature throughout the year, regardless of outside air conditions or fluctuations in the indoor climate. Dehumidification as low as 15% relative humidity can be reached at low temperatures (-20 to +40°C).

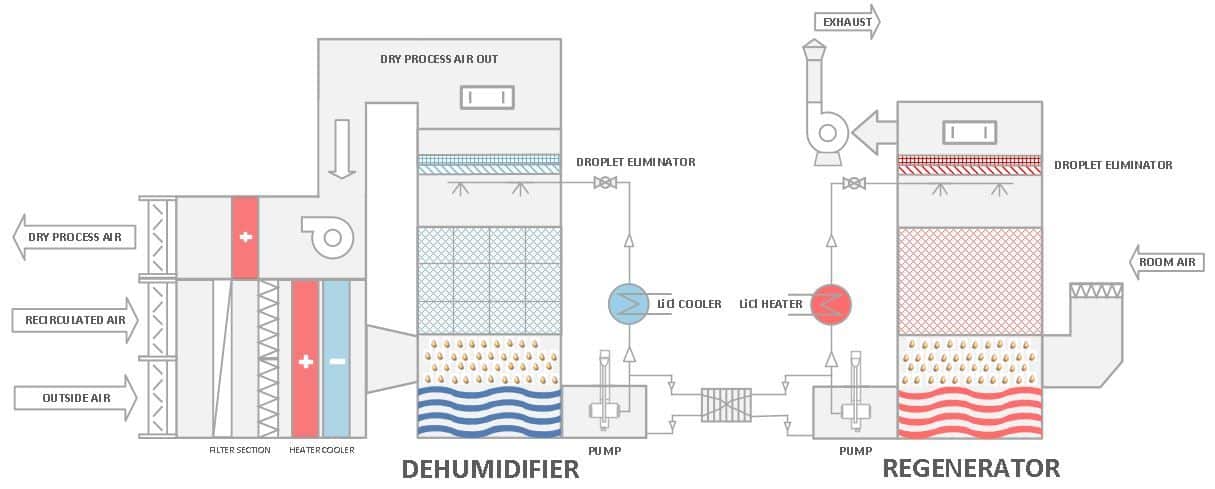

The Tema Process dehumidifier is using a Lithium Chloride salt solution as absorbent. Lithium Chloride is a very strong salt and has an equilibrium curve which closely follows the relative humidity curve of air. The process air will enter the countercurrent dehumidifier and will be dehumidified or humidified in order to maintain this equilibrium. In other words the sprayed salt concentration will control the outlet air relative humidity. By cooling the salt solution before spraying we are able to cool down the air temperature. In this way air temperature and air humidity are both controlled in the same system but can be adjusted independently.

As moisture is continuously absorbed by the salt solution inside the dehumidifier, it becomes diluted and slowly loses drying capacity. To evaporate this surplus of moisture the absorbent is pumped to the regenerator unit. Here the process is turned around, so by heating up the salt solution, moisture is released to an outside air stream and exhausted. The salt solution is continuously pumped between the units in order to provide precise conditions to the process.

Lithium Chloride is a chemically stable, non-toxic, non-vaporizing salt solution which acts as a biocide to mold, bacteria and micro-organisms. Beyond its physical desiccant nature Lithium Chloride is also an effective antifreeze.

Bacteria and odor free recirculated air

An extensive research project revealed that the Tema Process dehumidifier kills almost all airborne bacteria and microorganisms. The high Lithium Chloride concentration absorbs moisture from the air, but also effectively removes water from microorganisms present in this airstream. In this way almost all bacteria, fungi, mold, etc. are killed. Unlike UV light, which need to be replaced or cleaned, the bacterial-killing effect of Lithium Chloride is indefinite. This is a great additional advantage in processes and/or rooms where air decontamination is a requirement.

In addition to its excellent function as “bacteria killer”, the system also cleans the air of odors, gases and other pollutants that solve in water. This makes recirculation of energy interesting airstreams possible. Any impurities in these airstreams, are filtered and washed out of the air by the salt solution. The Tema system can also humidify the air by simply adding demineralized water or condensed water. This means that the system can dehumidify in summer and hygienically humidify the air during the dry winter months with the same equipment.

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety

Dehumidifier – Air handling units

All required additional components like air dampers, filters, fans, cooling and heating coils are built in an hygienic, easy accessible, fully cold-bridge free and sound absorbing air handling units. The inside and outside plating material can be manufactured from aluminum, galvanized steel or stainless steel depending on customer wishes.

- The PU isolation in between makes these units completely cold-bridge free. This way condensation will be completely prevented.

- The units can be easily accessed for maintenance purposes through double doors. By decoupling the internal and external door the fan sound is better absorbed and furthermore the isolation value is increased.

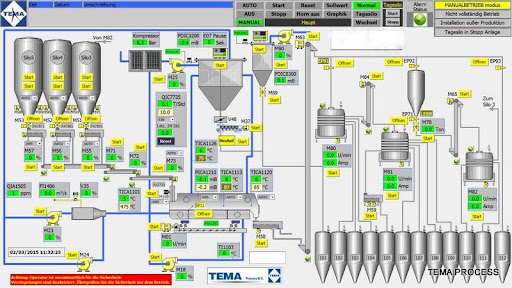

Sensors, control panel and visualization

The Tema Process control panel will steer, manage, calculate, control, monitor and protect the complete solution. These can be mechanical, hydraulic, electrical and/or pneumatic sensors, dampers and valves. They are all connected to the PLC control system, which can be easily integrated into the complete industrial automation system of your factory.

We have the experience with

- Programming of different PLC brands (mostly Siemens or Rockwell, Allen Bradley)

- Visualization of production processes by means of HMI and/or SCADA

- Remote control and can be linked to building management systems

Commitment to Sustainability

At TEMA Process, sustainability is at the core of our operations.Our innovative drying and processing solutions are meticulously engineered to reduce environmental impact, while enhancing efficiency and productivity. By transforming residual products and waste into valuable resources we support the circular economy and contribute to a greener future.

Want more info? download our technical sheet

Gain a comprehensive understanding of our diverse product range through our detailed technical sheets. Available in multiple languages, these sheets offer key insights to inform your decisions.

Enhance your knowledge with images included in our sheets that help elucidate the processes and their applications, making it easier for you to visualize and grasp the practical aspects of our products.