Tema Process Fluid Bed Dryers for the best Bread Crumb

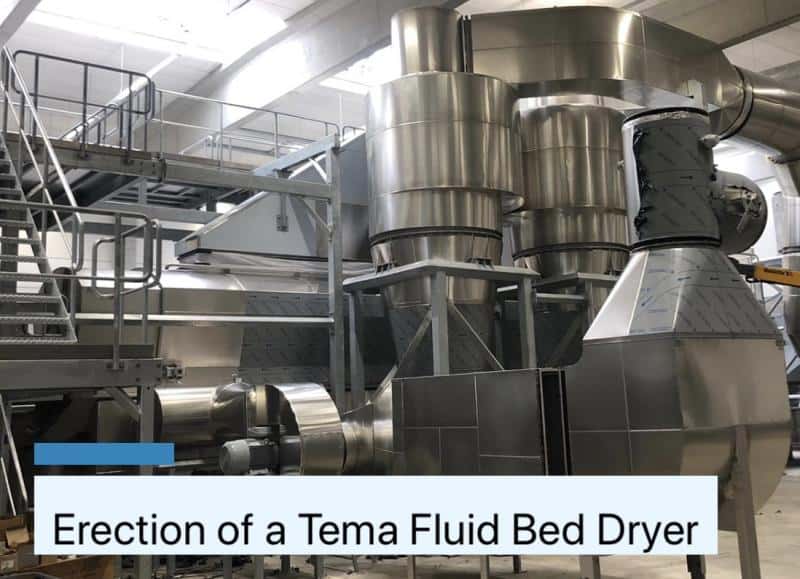

In traditional processes for manufacturing breadcrumbs, bread loaves are first dried and then crushed in a pinned disc mill or a hammer mill. Reversing the order — first reducing the size of the bread by milling and then drying the crumbs by means of a Tema Process fluidized bed drier has proved to be a more economical way. […]

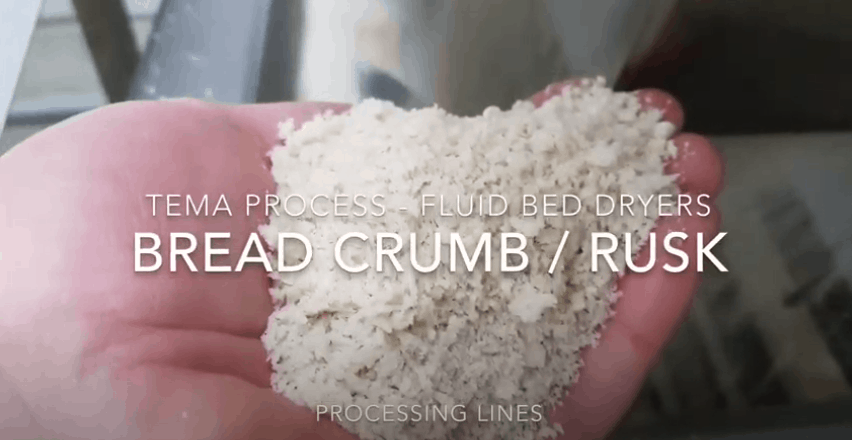

Breadcrumbs made by toasting the bread in the Tema Fluid bed dryer [video]

Breadcrumbs are made either by loaves or by sheeting, slitting and baking the dough followed by cooling, grinding, and drying the baked product. A golden coloured crust contributes colour to the breadcrumb. The crust is obtained either by the conventional baking process itself or by toasting the bread in the Tema Fluid bed dryer.

Drying extruded cereal and bread crumb products

Drying extruded cereal and bread crumb products: A extrusion line in combination with a fluid bed dryer transforms agriculture raw materials into edible crispy products. These products can vary in color, composition, format, taste, bite, and texture depending on market demand. The Tema Process production lines are available in a wide range of capacities starting from 500 kg/hr up to 6.000 kg/hr.

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety