Breadcrumbs made by toasting the bread in the Tema Fluid bed dryer [video]

Breadcrumbs are made either by loaves or by sheeting, slitting and baking the dough followed by cooling, grinding, and drying the baked product. A golden coloured crust contributes colour to the breadcrumb. The crust is obtained either by the conventional baking process itself or by toasting the bread in the Tema Fluid bed dryer.

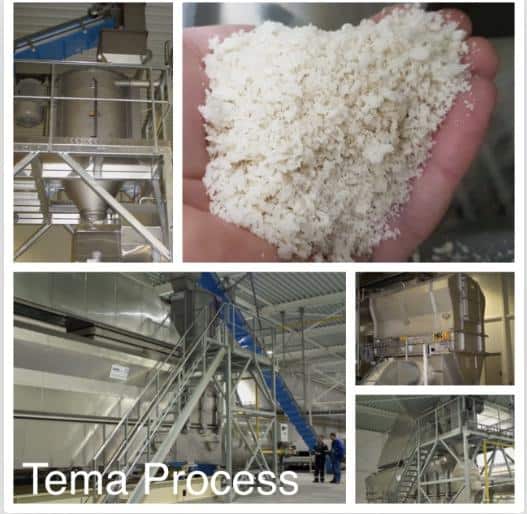

Leading supplier of breadcrumb, panko and rusk production lines

TEMA Process is the leading supplier of breadcrumb, panko and rusk production lines (drying/toasting/cooling). Bread crumbs have three basic uses: coating, binding and topping. The TEMA production line can be delivered in sizes ranging from 500 kg/hr to 6.000 kg/hr output. For energy savings the fluid bed dryer is equipped with an integrated heat recovery system.

fluid bed dryer for breadcrumb

TEMA Breadcrumb Processing line. Much of breadcrumb production worldwide is dedicated to processed foods either as a coating, called breading or crumbing, or as a filler to add inexpensive bulk and flavor. A Tema bread crumb / rusk process production line consists of a bread mill, a fluid bed dryer/cooler, gas burner, supply fan, recirculation system, exhaust blower, cyclone(s), cooling fan with filter, ductwork and [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety