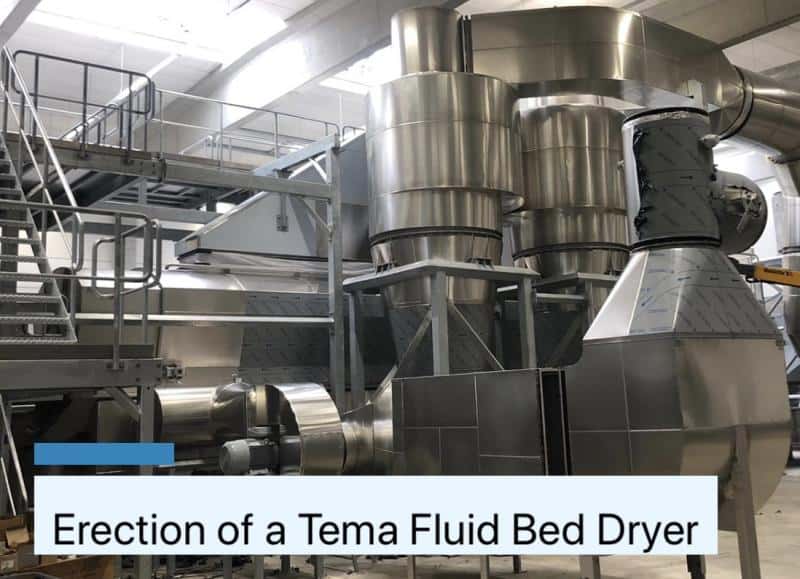

Tema Fluid Bed Dryers: Factory Acceptance Test (FAT)

Tema Fluid Bed Dryers. A Factory Acceptance Test (FAT) is a formal test and inspection work process that is performed at our Tema process workshop and is done when the system is fully fabricated and assembled prior to the shipping. The FAT is to check the functionality and capabilities of the equipment. […]

Tema multi zone, one hull design dryers

Tema multi zone, one hull design dryers This type of Fluid bed system has several inlet and exhaust air compartments, each of which is equipped with its own supply air system (heating or cooling). Process parameters for each zone (temperature and flow) can therefore be adjusted to provide maximum control of the process and product characteristics. The system can handle multiple recipes with varying process parameters. A [...]

New Assembly Facility

We are proud to present you our new assembly facility. With this new facility we'll create new opportunities for assembling parts and machines. Together with our customers we want to grow to our next level. We support the industry in its energy transition, providing the best available technologies for drying products on a industrial scale: * Reuse residual/waste heat * Increase the residual heat potential [...]

Tema Process Condenser Scrubbers

Tema Process Condenser Scrubbers are designed to condense, absorb, cool and scrub large volume of exhaust gases. These scrubbers are used in the Tema Process closed loop drying system. The Closed Loop Dryers are designed as a closed system in which heated air used to dry the materials is continuously recycled within the drying compartment of the dryer without being discharged to the atmosphere, thus [...]

Drying extruded cereal and bread crumb products

Drying extruded cereal and bread crumb products: A extrusion line in combination with a fluid bed dryer transforms agriculture raw materials into edible crispy products. These products can vary in color, composition, format, taste, bite, and texture depending on market demand. The Tema Process production lines are available in a wide range of capacities starting from 500 kg/hr up to 6.000 kg/hr.

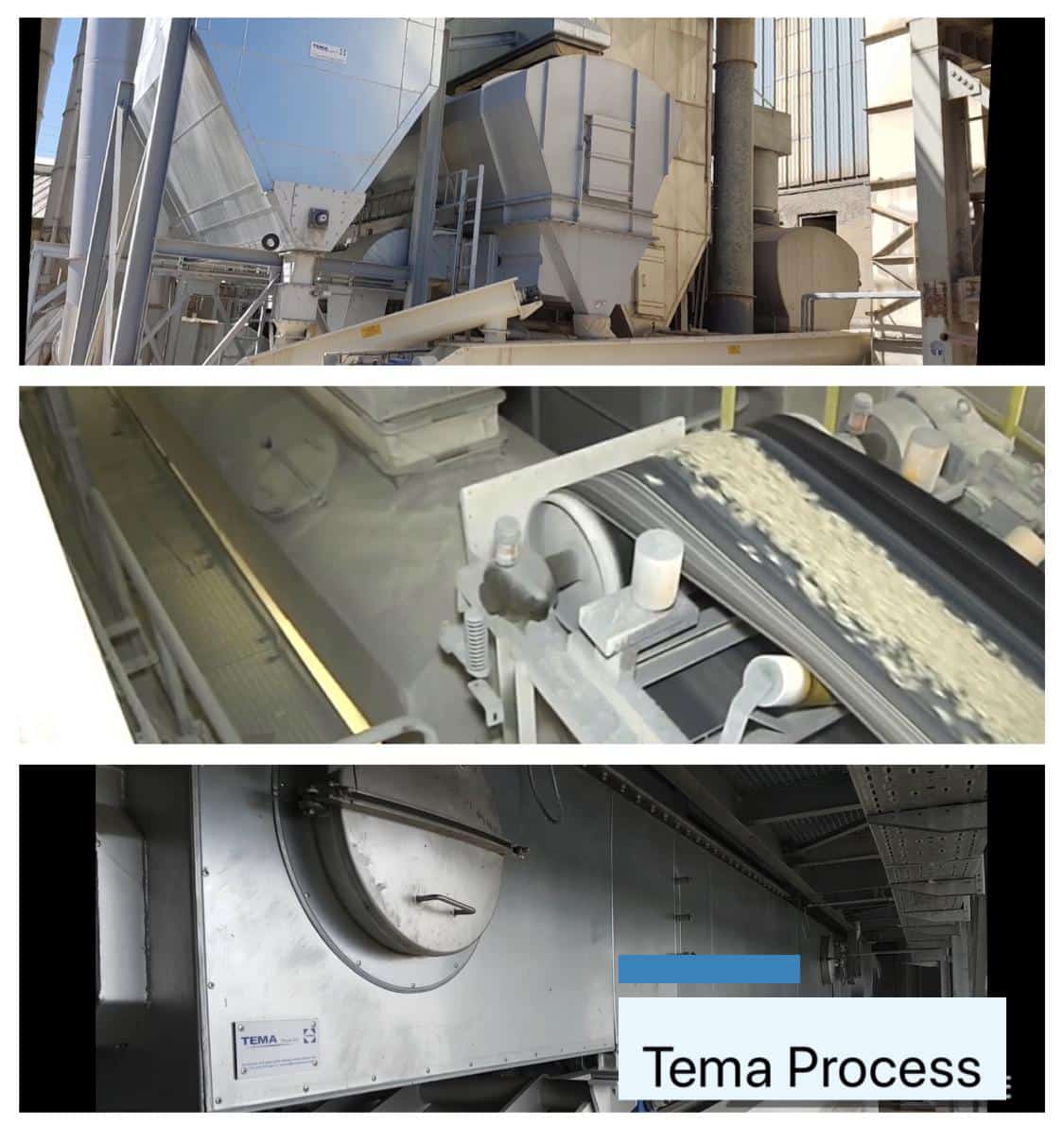

Drying Bentonite (clay) using Tema Process fluid bed dryer

Bentonite (clay) dryer: Bentonite is the commercial name of a whole range of natural clays with a high water absorption capacity causing it to expand and swell. Bentonites may contain in addition a variety of accessory minerals. These may include lesser amounts of other clay minerals such as kaolin, mica, illite, as well as non-clay minerals like quartz, feldspar, calcite, and gypsum. Uses: purification, drilling [...]

Tema wide dust recovery hood captures airborne particles and returns it to the process [video]

Tema wide dust recovery hood captures airborne particles and returns it to the process. The Tema fluid bed dryers are equipped with a special designed wide hood that reduces the airflow velocity. As a result of this velocity drop, gravity takes over and the fluidised product will remain in the dryer. The expanded hood cuts the volume of product lost as waste and increases the [...]

Manure & Digestate Drying – MANURESOURCE INTERNATIONAL CONFERENCE

Manure & Digestate Drying MANURESOURCE INTERNATIONAL CONFERENCE ManuREsource is an international conference stimulating the exchange of experiences between regions on the policy measures taken for coping with manure surpluses, both in terms of manure management in a broad sense, and more specifically in terms of manure treatment. This conference also aims to give an overview of the current developments and innovations in manure treatment technologies [...]

TEMA Process Hygienic Cyclones

TEMA Process Hygienic Cyclones are used to separate the fine particles from the exhaust air of the fluid bed dryer/cooler and full fills the requirements for use in highly sanitary applications in industries such as food and chemical industry. Tema engineers and manufactures sanitary cyclones according to the requirements of the food and dairy industry, including a wide range of sanitary and industrial Clean-in-Place (CIP) [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety

![Tema wide dust recovery hood captures airborne particles and returns it to the process [video]](https://temaprocess.com/wp-content/uploads/2019/12/Tema-wide-dust-recovery-hood-captures-airborne-particles-and-returns-it-to-the-process-video.png)