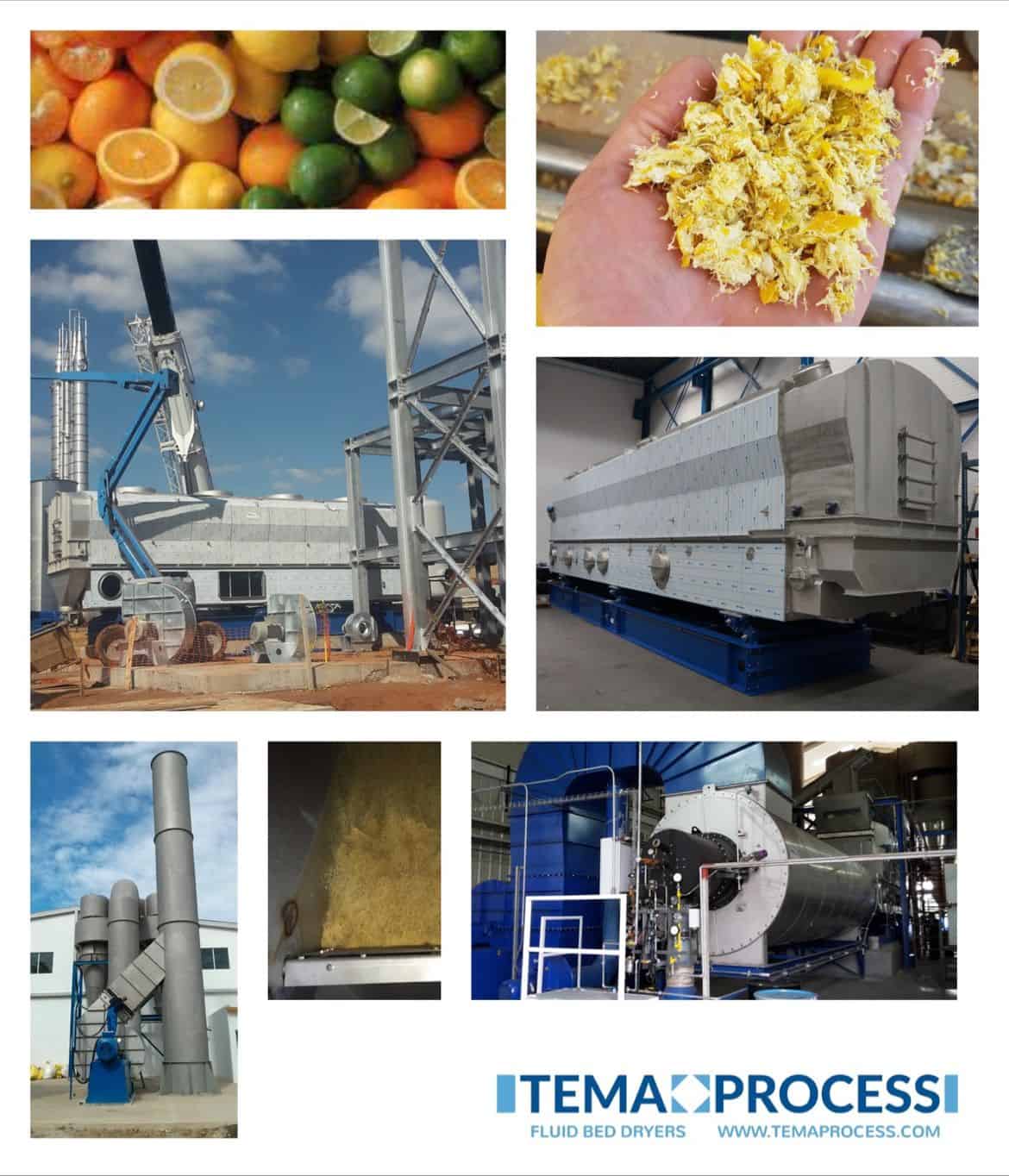

Drying of citrus peels & pulp

Drying citrus peel is the first step of utilizing that by-product in the food and feed industry. Much of the pulp is dried and exported around the world. It is easier to haul and manage and can be stored year-round. Drying is usually done at the fruit processing site to save on transportation costs Citrus pulp is used as a cereal substitute in ruminant feeds, [...]

Industrial citrus peel drying

Drying citrus peel on an industrial scale is a common process used to preserve the peels for various applications in the food, beverage, pharmaceutical, and cosmetic industries. The drying process removes the moisture from the peels, extending their shelf life and making them easier to handle and transport. Drying citrus peels concentrates the natural flavour and aroma compounds present in the peels. This concentrated flavour [...]

Process combined ethanol stripper / dryer with ethanol recovery

Today pectin is mostly produced from citrus peels (lemons, limes and oranges). After juice extraction, essential oil and dissolved sugars are removed from the peel prior to drying. Prior to pectin extraction with dilute mineral acids, the citrus peel must be dried from the starting level of about 85% moisture, down to 10 to 12% moisture to avoid fermentation. Because of the high water content [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety