Applications of fluid bed dryers & coolers

Fluid bed dryers and coolers are widely used to dry, cool and condition powders and granules with uniform product quality and high energy efficiency. They are applied across multiple industries, including: - Food & feed – breadcrumbs, cereals, starches, sugars, additives - Chemicals – crystals, powders, polymers, specialty chemicals - Nutraceuticals – granules, pellets, excipients - Minerals & mining – sand, ores, mineral concentrates - [...]

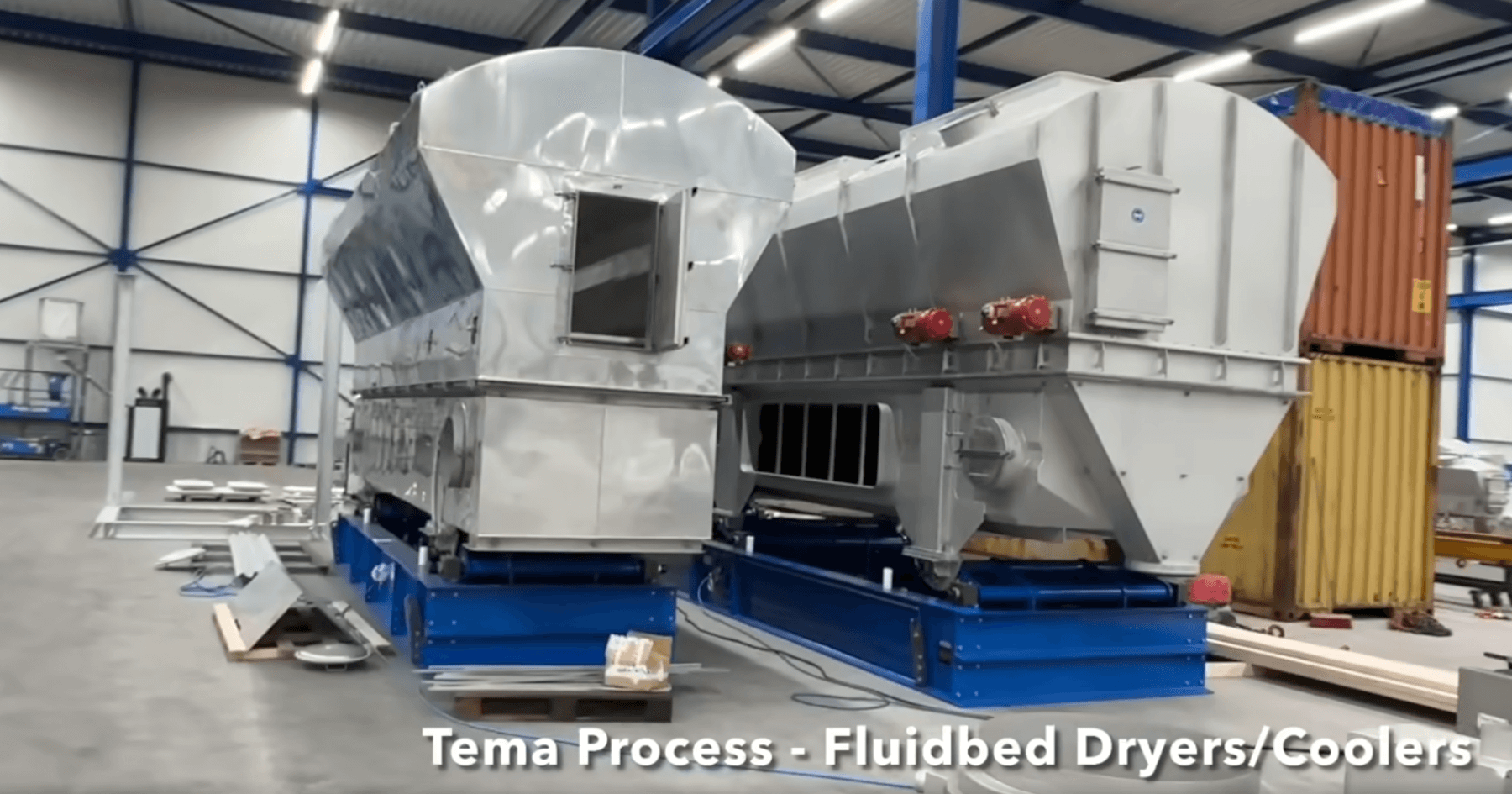

Six Tema Process fluid bed dryers/coolers ready for shipment

Another milestone achieved: six Tema Process fluid bed dryers/coolers completed and ready for shipment to our worldwide clients in the food, chemical, waste, and mineral industries. […]

Installing a TEMA Process Fluidized Bed Dryer/Cooler: What You Need to Know

Whether you're in the chemical, food processing, or mineral industry, a TEMA Fluidized Bed Dryer/Cooler (FBD) is a high-performance system — but it only delivers optimal results if installed and commissioned properly. Below is a concise technical overview of what's required for successful installation and integration: 1. Site Preparation Proper foundation (typically concrete) Utility checks: compressed air, steam/electricity/gas, cooling water, exhaust GMP zoning or hygienic [...]

TEMA Fluidbed Dryers/Coolers – Robust, Energy-Efficient Solutions for Mineral Drying.

TEMA fluidbed dryers and coolers are ideal for drying and cooling mineral materials. Designed for outdoor installation, they can withstand harsh environments and continuous operation without compromising performance. Their rugged construction ensures minimal wear, even when processing abrasive products such as sand, limestone, or metal ores. In addition, TEMA dryers are engineered for low energy consumption, helping reduce operational costs and environmental impact. Key advantages [...]

Tema Process SLS Shaking Fluidbed Coolers

Tema Process SLS Shaking Fluidbed Coolers ready for transport: Sodium Lauryl Sulfate (SLS) Needle, also known as Sodium Dodecyl Sulfate (SDS), is an anionic surfactant widely recognized for its properties as a detergent and foaming agent. It is characterized by its needle or flake-like appearance, ranging from white to light yellow. […]

Containerized Fluid Bed dryer/cooler

Video of a Containerized Fluid Bed dryer/cooler. […]

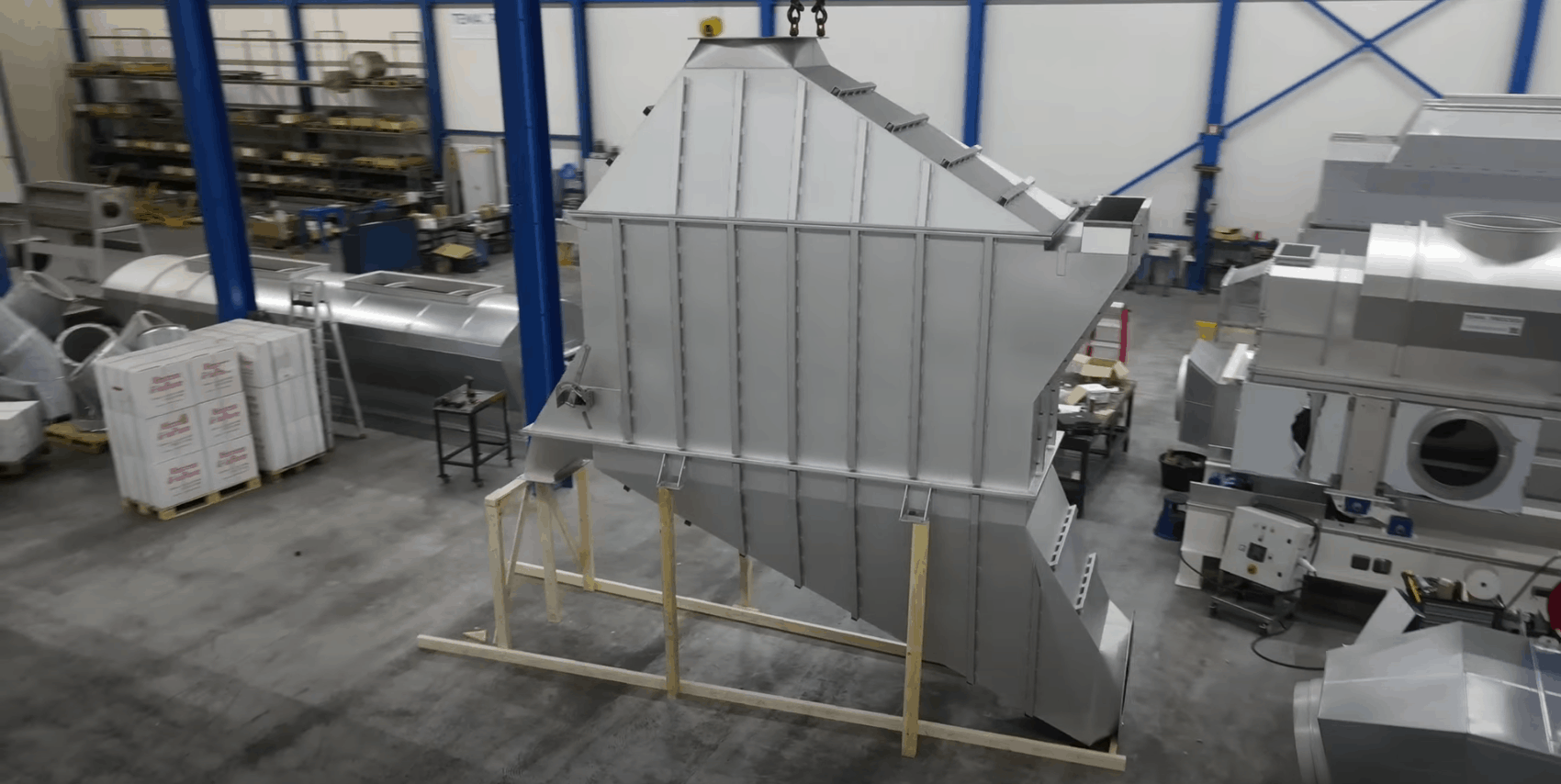

Fluidbed dryers / coolers

The sanitary execution Tema Process Fluidbed dryers / coolers have a hygienic single hull design (bedplate, windbox and suction hood are welded together) and are equipped with a Washing-In-Place (WIP) system. The WIP is an automated system used to clean the interior surfaces of the fluid bed dryer ducting etc. […]

Energy efficient Fluid Bed Dryers and Coolers

Tema Process Fluid Bed Dryers and Coolers are known worldwide for their high quality and efficient operation. Our Fluid Bed Dryers are used in all types of industries for Drying and Cooling of all kinds of products. When drying large volumes of material, energy consumption is the greatest controllable expense. Tema fluid bed dryers maximize return on investment by reducing energy expenses.

Tema Fluid Bed Drying / Cooling System

* Fluid Bed Technology is an energy efficient process to dry, cool and/or separate powder particles. * The product falls into a fluid bed. Warm and cool air is introduced into an air plenum for gentle final drying, cooling, and/or separation of the product. * Equipped with liquid-activated retractable CIP Spray Nozzles and Fire Suppression Nozzles that provide safe and hygienic processing.

Static (non-shaking) fluidised bed

Static (non-shaking) fluidised bed or fluid bed (dryers and coolers) are used on free flowing fluidised bulk materials that have a narrow particle size distribution. The static fluid bed remains stationary during operation. Static fluid bed dryers can be continuous or batch operation and may be round or rectangular. The other type of fluid bed dryer is a shaking fluid bed dryer or cooler, where the body [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety