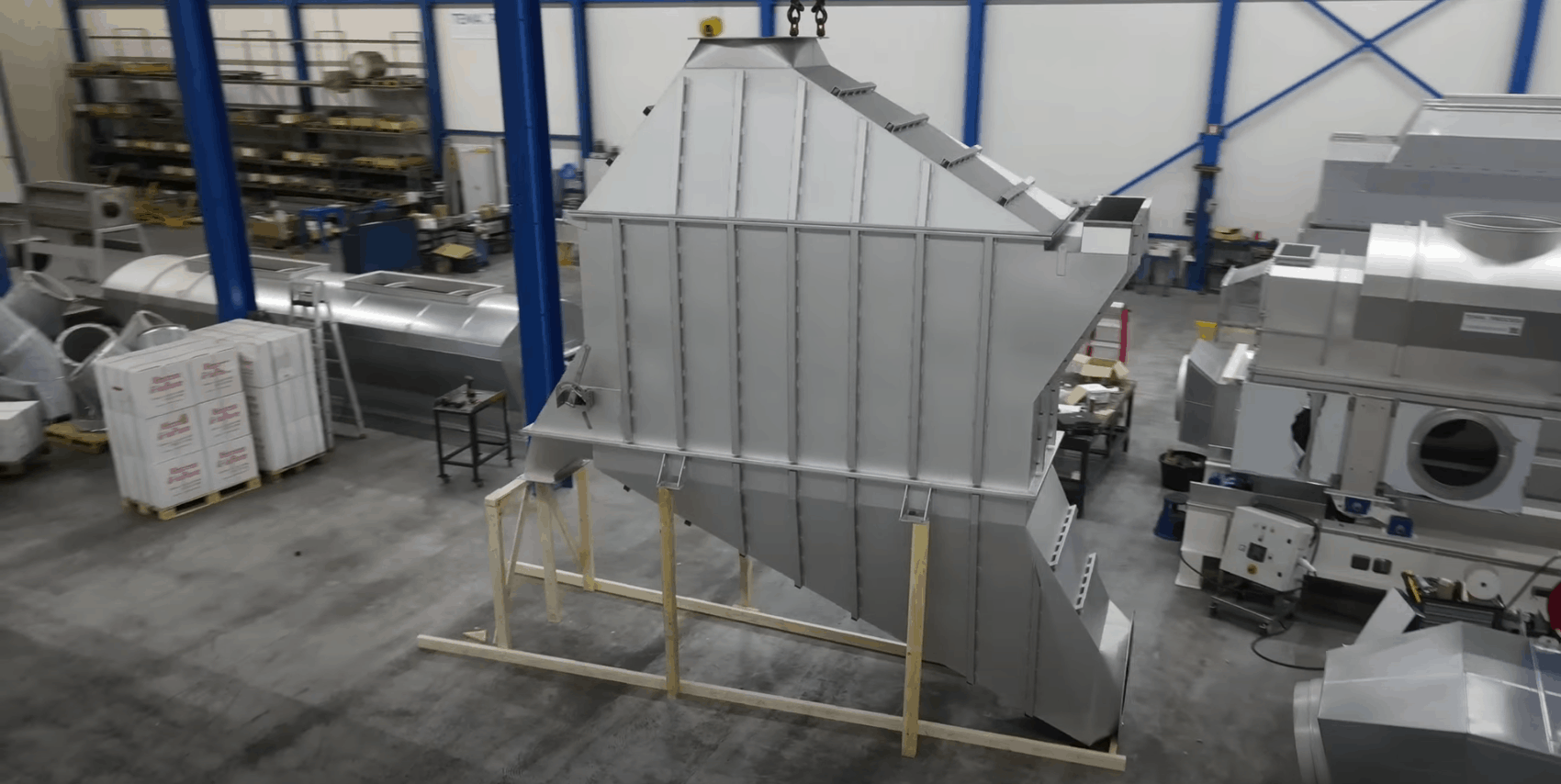

Fluidbed dryers / coolers

The sanitary execution Tema Process Fluidbed dryers / coolers have a hygienic single hull design (bedplate, windbox and suction hood are welded together) and are equipped with a Washing-In-Place (WIP) system. The WIP is an automated system used to clean the interior surfaces of the fluid bed dryer ducting etc. […]

Energy efficient Fluid Bed Dryers and Coolers

Tema Process Fluid Bed Dryers and Coolers are known worldwide for their high quality and efficient operation. Our Fluid Bed Dryers are used in all types of industries for Drying and Cooling of all kinds of products. When drying large volumes of material, energy consumption is the greatest controllable expense. Tema fluid bed dryers maximize return on investment by reducing energy expenses.

Tema Fluid Bed Drying / Cooling System

* Fluid Bed Technology is an energy efficient process to dry, cool and/or separate powder particles. * The product falls into a fluid bed. Warm and cool air is introduced into an air plenum for gentle final drying, cooling, and/or separation of the product. * Equipped with liquid-activated retractable CIP Spray Nozzles and Fire Suppression Nozzles that provide safe and hygienic processing.

Static (non-shaking) fluidised bed

Static (non-shaking) fluidised bed or fluid bed (dryers and coolers) are used on free flowing fluidised bulk materials that have a narrow particle size distribution. The static fluid bed remains stationary during operation. Static fluid bed dryers can be continuous or batch operation and may be round or rectangular. The other type of fluid bed dryer is a shaking fluid bed dryer or cooler, where the body [...]

Dryer/cooler process, how does it work?

Fluid bed Process. I often get the questions : What does fluidised bed mean? How does a fluidisation work? What is the purpose of fluidisation? Etc. In a couple of chapters, I like to explain more about this technology/process and where the system can be used. […]

Fluid bed dryer/cooler, how does it work?

I often get the questions : What does fluidised bed mean? How does a fluidisation work? What is the purpose of fluidisation? Etc. In a couple of chapters, I like to explain more about this technology/process and where the system can be used. […]

Fluidized Bed Dryers/Coolers for the food/feed industry

Fluidized Bed Dryers/Coolers for the food/feed industry: Bread crumb • Rusk • Croutons • Soy • Starch • Citric acid • Animal Feed • Baby food • Baking additive • Bread waste • Cacao • Casein • Chicken meat • Chocolate • Coffee • Coffee granulates • Corn flour • Dextrose • Edible fat • Egg powder • Flavours • Flour • Fruit products • [...]

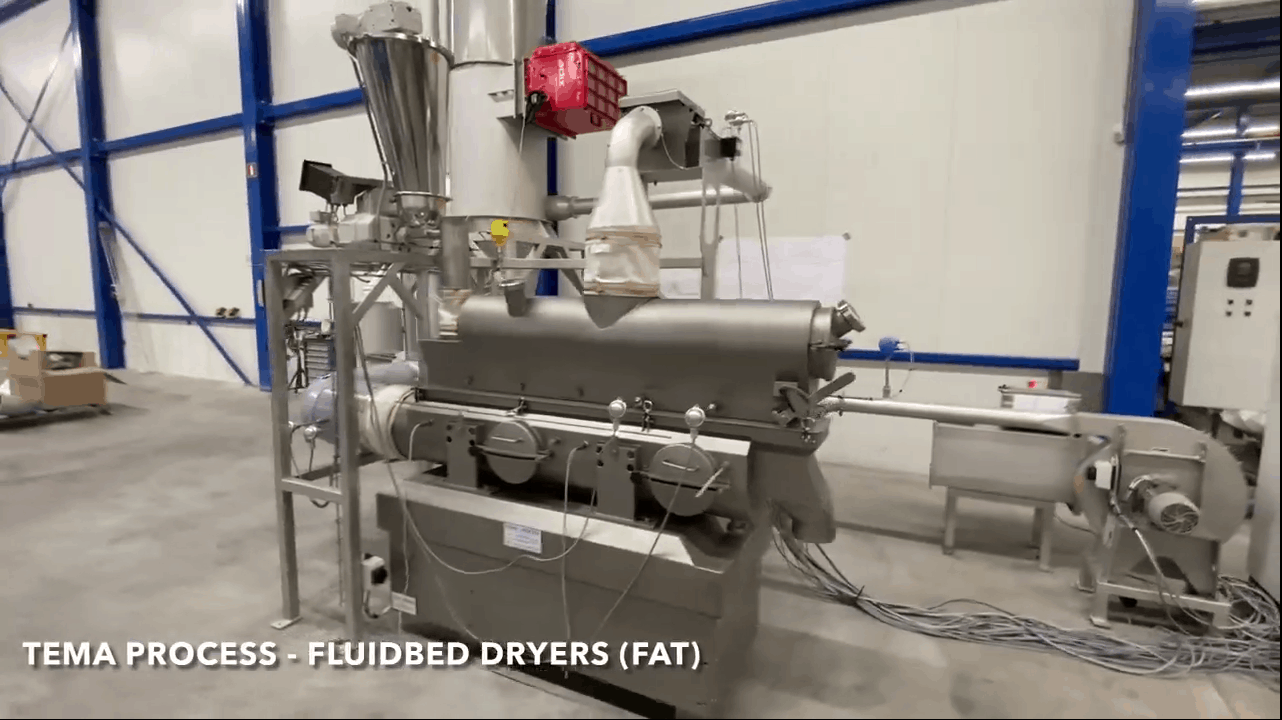

Factory Acceptance Test

Factory Acceptance Test (FAT in our workshop) of a R&D Fluid Bed Dryer/cooler. TEMA Process product portfolio includes a wide range of sizes to cover all the steps from R&D (0,16 m2) to production scale (36 m2). Regardless of size, our fluid bed systems with their compact design and their durable structure, will produce results that optimise the production process with outstanding results in quality, [...]

Sugar cooling

Cooling is as important for sugar storing and sugar quality as the drying process. Like a fluid bed dryer, the fluid bed cooler also uses the principle of fluidisation for maximum exposure of surface for cooling action. The fluid bed coolers are designed to cool all kind of products at a variety of feed rates. Cooling may be intensified by means of an air cooling [...]

Fluidized bed coolers

Like a fluid bed dryer, the Fluid Bed Cooler also uses the principle of fluidisation for maximum exposure of surface for cooling action. Tema fluid bed coolers are designed to cool all kind of products at a variety of feed rates. The fluid bed coolers gently handle almost any product.

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety