Dryers for sand

Drying sand Typically, sand is mined, washed and screened and stored in piles with various grades. The sand needs to be dried to the required moisture content before it can be sold or further processed. Silica sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules. Silica sand is the primary component of all types [...]

Drying Processes for Black Soldier Fly Larvae

Optimizing Drying Processes for Black Soldier Fly Larvae Using Fluidized Bed Dryers with Plug Flow. Introduction. Black Soldier Fly (BSF) larvae have gained significant attention in recent years due to their versatile applications in waste management, animal feed production, and even human consumption. One critical aspect of utilizing BSF larvae is the drying process, which plays a crucial role in preserving their nutritional value and [...]

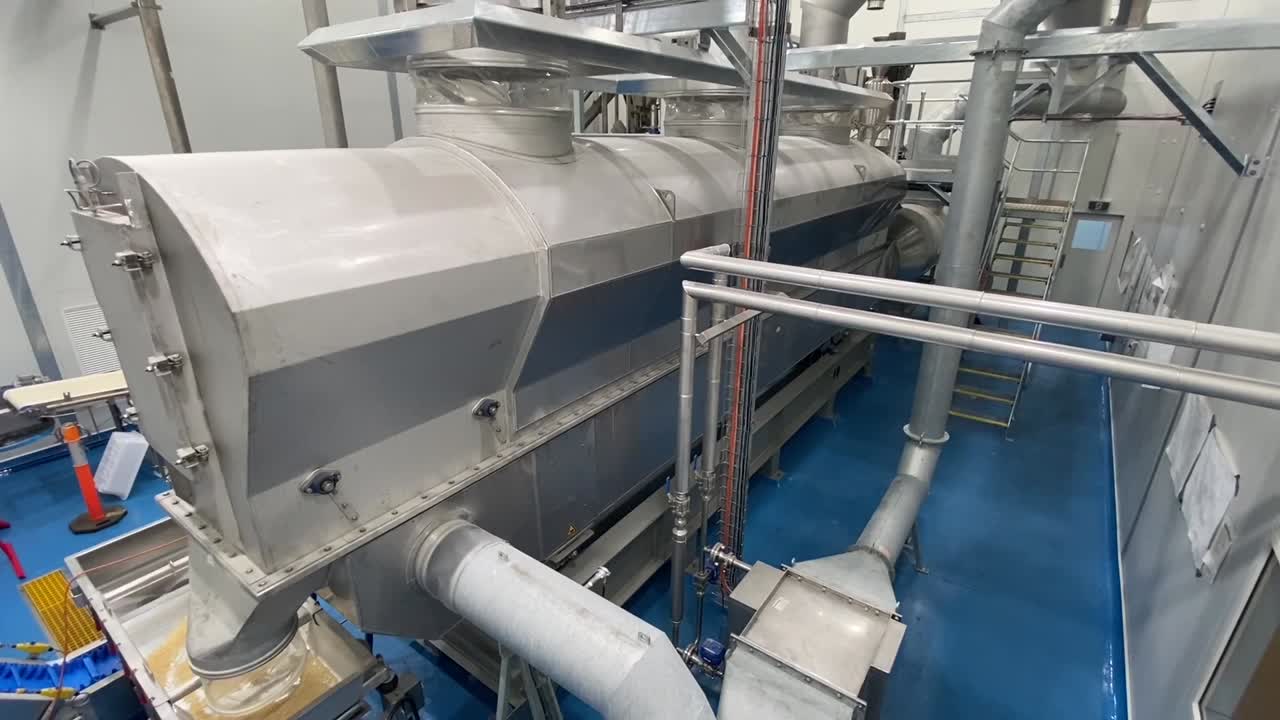

Fluidbed dryers / coolers

The sanitary execution Tema Process Fluidbed dryers / coolers have a hygienic single hull design (bedplate, windbox and suction hood are welded together) and are equipped with a Washing-In-Place (WIP) system. The WIP is an automated system used to clean the interior surfaces of the fluid bed dryer ducting etc. […]

Sodium sulfate – Fluid Bed Dryer

Sodium sulfate (sulfate of soda , Na2SO4). The largest use is as filler in powdered home laundry detergents. It can also be used to add strength and toughness to paper and to make glass. During the drying process the bed temperature is uniform and the drying takes place at relative low temperatures. The fluidized bed drying is known as a drying method capable of efficiently [...]

Ammonium Sulfate – Fluid Bed Dryer

Ammonium Sulfate / (NH4)2SO4 - TEMA Process Fluid Bed Dryer Ammonium Sulfate (Ammonium sulphate, (NH4)2SO4), is an inorganic salt with a number of commercial uses. The most common use is as a soil fertilizer. Ammonium sulfate crystals are formed by circulating the ammonium sulfate liquor through a water evaporator, which thickens the solution. Ammonium sulfate crystals are separated from the liquor in a centrifuge. The [...]

Animation – Tema Process Fluid Bed Dryer

Discover the Fascinating TEMA Process Fluid Bed Dryers. Join us on a captivating journey as we unveil our cutting-edge technology of efficient drying in this animated video! […]

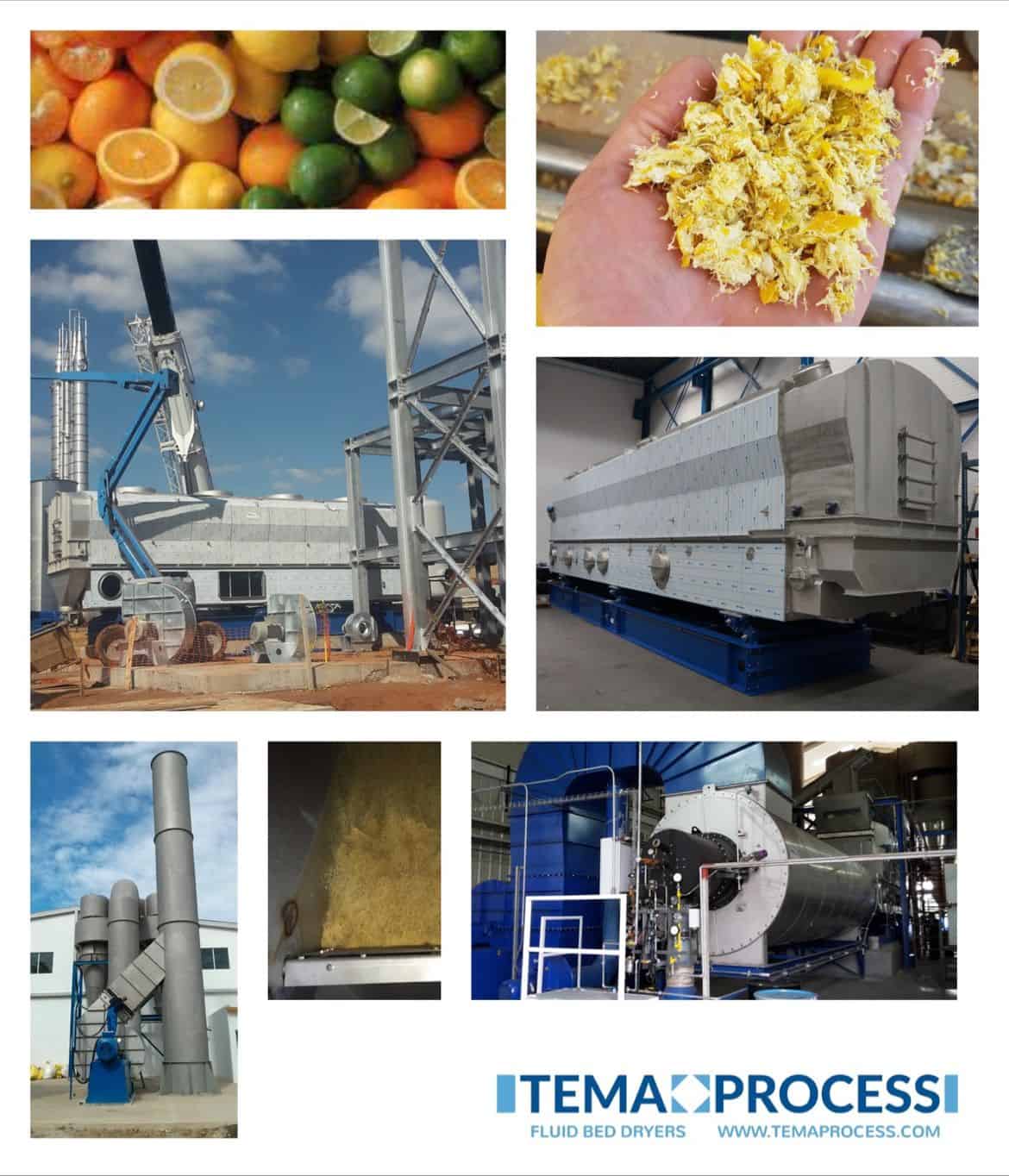

Drying of citrus peels & pulp

Drying citrus peel is the first step of utilizing that by-product in the food and feed industry. Much of the pulp is dried and exported around the world. It is easier to haul and manage and can be stored year-round. Drying is usually done at the fruit processing site to save on transportation costs Citrus pulp is used as a cereal substitute in ruminant feeds, [...]

Fluid bed dryer for salt

Sea salt is salt produced from the evaporation of seawater. Its use is practical only in warm climates where the evaporation rate exceeds the precipitation rate, either annually or for extended periods, and ideally, where there are steady prevailing winds. When an adequate layer of salt has built up on the pan floor, harvesting commences. A machine digs up the salt, deposits it onto a conveyor [...]

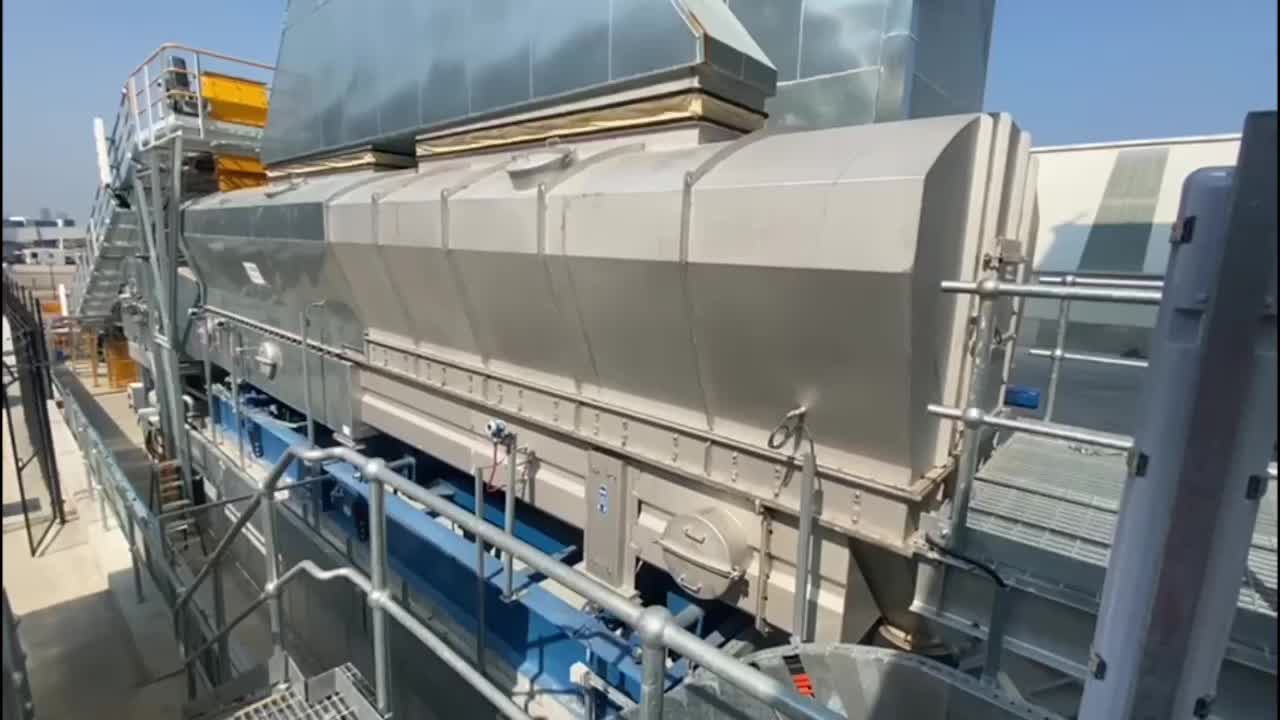

Industrial citrus peel drying

Drying citrus peel on an industrial scale is a common process used to preserve the peels for various applications in the food, beverage, pharmaceutical, and cosmetic industries. The drying process removes the moisture from the peels, extending their shelf life and making them easier to handle and transport. Drying citrus peels concentrates the natural flavour and aroma compounds present in the peels. This concentrated flavour [...]

Fluidised bed dryers – Exhaust air system

The packed tower scrubbers are used to remove particulate and / or vapor contaminants from an exhaust gas stream by way of dilution or absorption. A packed tower is an efficient method of carrying out mass transfer between gas and liquid phases. Packed tower scrubbers incorporate packing media to facilitate intimate contact between a scrubbing liquid and gas to be scrubbed. Applications are: reduction of [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety