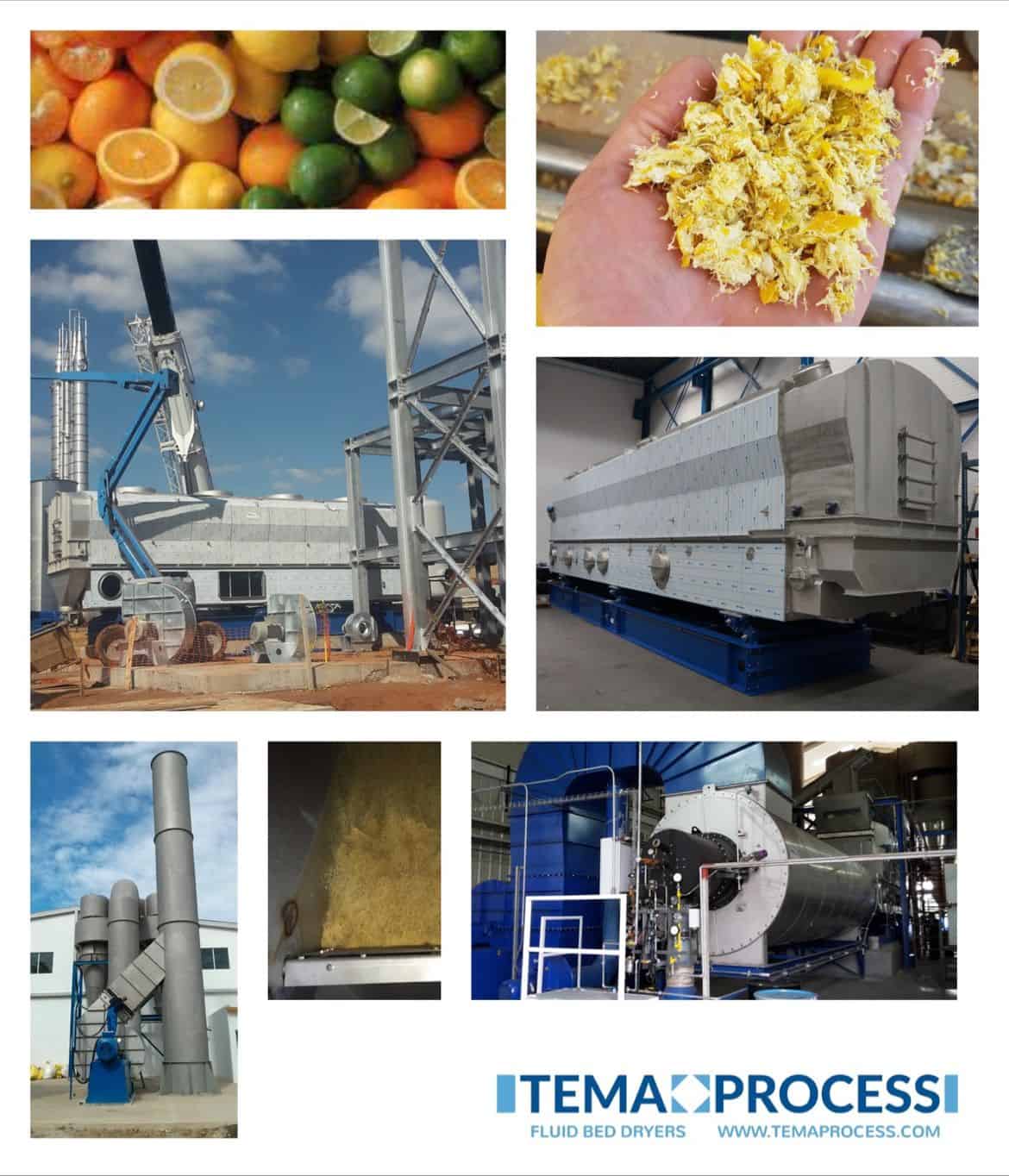

Drying of citrus peels & pulp

Drying citrus peel is the first step of utilizing that by-product in the food and feed industry. Much of the pulp is dried and exported around the world. It is easier to haul and manage and can be stored year-round. Drying is usually done at the fruit processing site to save on transportation costs Citrus pulp is used as a cereal substitute in ruminant feeds, [...]

Fluid bed dryer for salt

Sea salt is salt produced from the evaporation of seawater. Its use is practical only in warm climates where the evaporation rate exceeds the precipitation rate, either annually or for extended periods, and ideally, where there are steady prevailing winds. When an adequate layer of salt has built up on the pan floor, harvesting commences. A machine digs up the salt, deposits it onto a conveyor [...]

Industrial citrus peel drying

Drying citrus peel on an industrial scale is a common process used to preserve the peels for various applications in the food, beverage, pharmaceutical, and cosmetic industries. The drying process removes the moisture from the peels, extending their shelf life and making them easier to handle and transport. Drying citrus peels concentrates the natural flavour and aroma compounds present in the peels. This concentrated flavour [...]

Fluidised bed dryers – Exhaust air system

The packed tower scrubbers are used to remove particulate and / or vapor contaminants from an exhaust gas stream by way of dilution or absorption. A packed tower is an efficient method of carrying out mass transfer between gas and liquid phases. Packed tower scrubbers incorporate packing media to facilitate intimate contact between a scrubbing liquid and gas to be scrubbed. Applications are: reduction of [...]

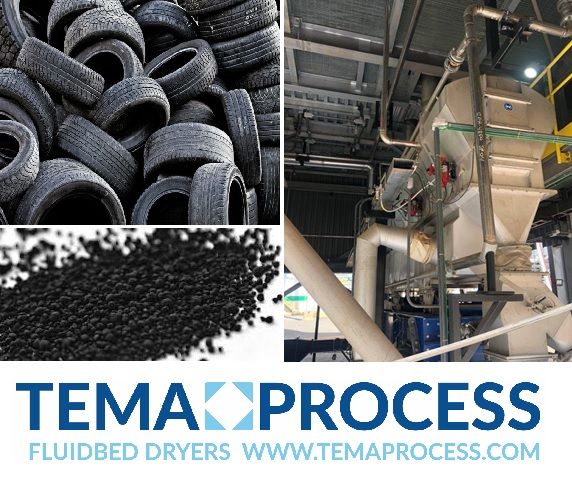

Carbon black fluid bed dryer

Carbon black is a material produced by the incomplete combustion of heavy petroleum products. Traditionally Carbon Black (CB) has been used as both a reinforcing agent and filler in automobile tires. Along with better understanding of CB’s unique properties as a material, it is presently used in a much wider range of applications across a large variety of products – car tires, conveyor belts, inks, plastic [...]

Tema Fluid Bed Drying / Cooling System

* Fluid Bed Technology is an energy efficient process to dry, cool and/or separate powder particles. * The product falls into a fluid bed. Warm and cool air is introduced into an air plenum for gentle final drying, cooling, and/or separation of the product. * Equipped with liquid-activated retractable CIP Spray Nozzles and Fire Suppression Nozzles that provide safe and hygienic processing.

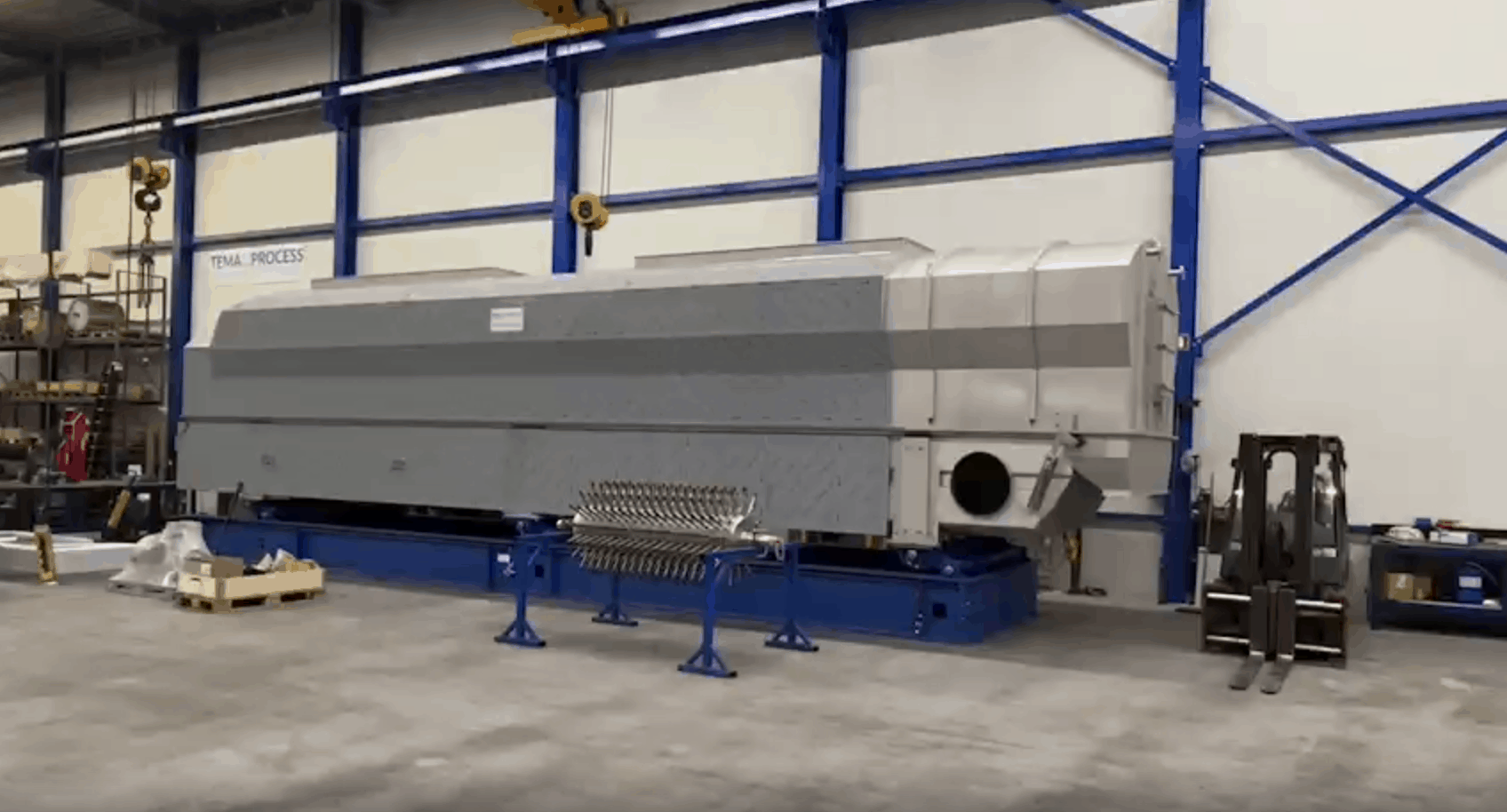

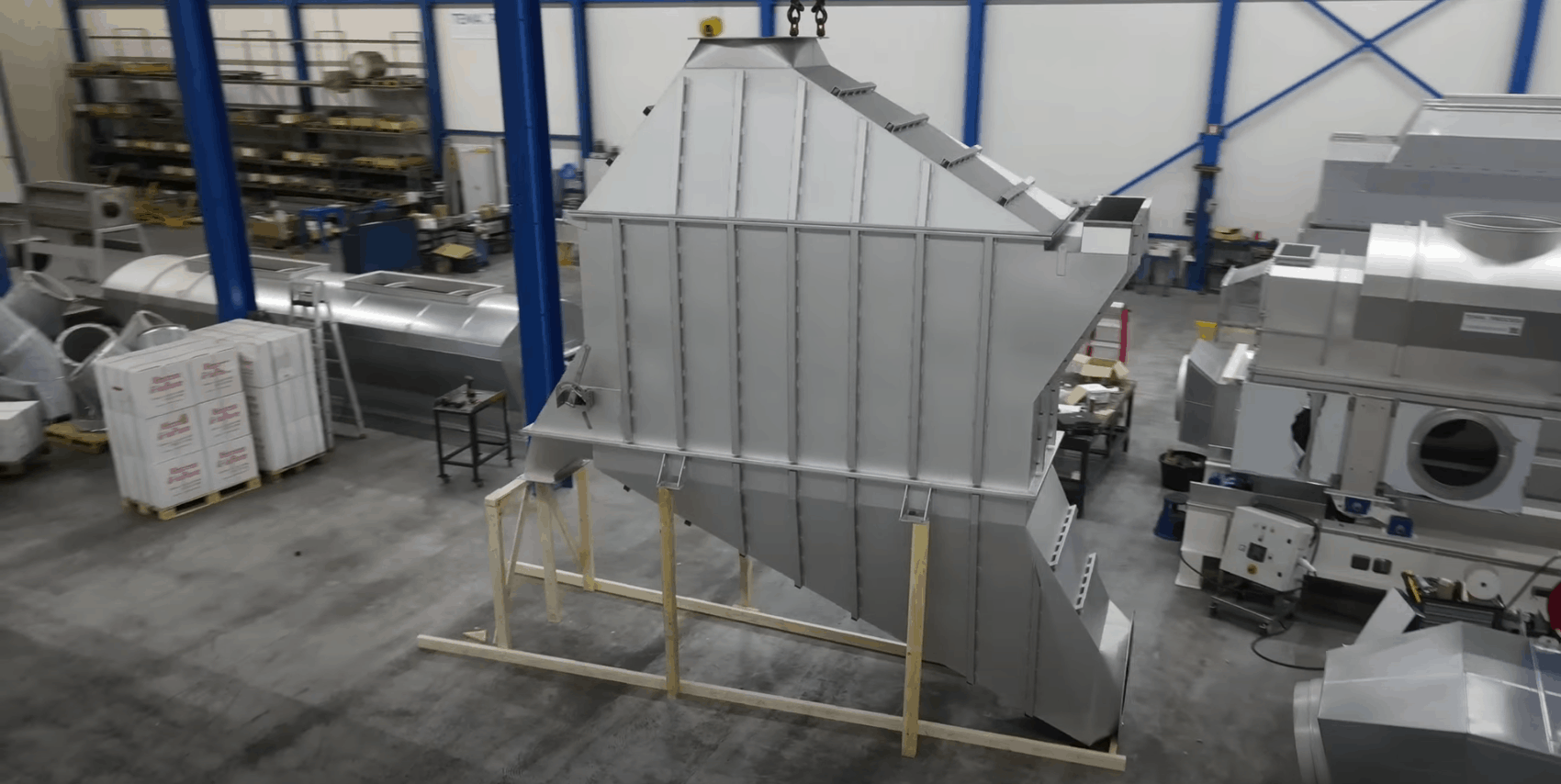

Dryers ready for Shipment!

Thermal drying is a process found in almost all industries. There are various choices of fluidized bed dryers available. Particles/powders are classified into major groups according to their characteristics when exposed to fluidizing gas stream, this is used as the main criteria for selection of Fluid Bed Dryer/Cooler for a particular application. An efficient drying technology: desired quality at minimum cost, low carbon footprint and [...]

Sand Dryers for India – Ready for shipment

Tema Process is the leading international manufacturer of fluidbed drying systems. The company owes its strong growth to consistently delivering high quality consultancy, process improvements and efficient tailor-made solutions for a range of industrial sectors, including the food, feed, chemicals, minerals and recycling industries.

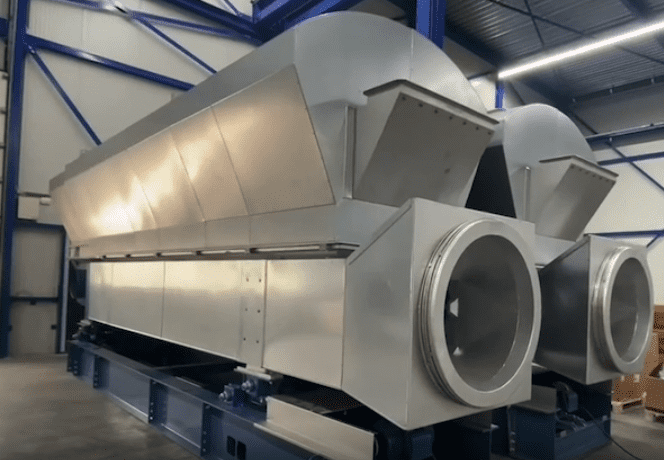

Static (non-shaking) fluidised bed

Static (non-shaking) fluidised bed or fluid bed (dryers and coolers) are used on free flowing fluidised bulk materials that have a narrow particle size distribution. The static fluid bed remains stationary during operation. Static fluid bed dryers can be continuous or batch operation and may be round or rectangular. The other type of fluid bed dryer is a shaking fluid bed dryer or cooler, where the body [...]

Meatless Fluid bed dryer Tema Process

Meatless Fluid bed dryer Tema Process video […]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety