Dryer/cooler process, how does it work?

Fluid bed Process. I often get the questions : What does fluidised bed mean? How does a fluidisation work? What is the purpose of fluidisation? Etc. In a couple of chapters, I like to explain more about this technology/process and where the system can be used. […]

Fluid bed dryer/cooler, how does it work?

I often get the questions : What does fluidised bed mean? How does a fluidisation work? What is the purpose of fluidisation? Etc. In a couple of chapters, I like to explain more about this technology/process and where the system can be used. […]

Clean-In-Place Systems for Fluidbed dryers

Tema Process offers an automated Clean-In-Place (CIP) System that provides a reliable, repeatable cleaning cycle for processing plants to operate efficiently and cost effectively to meet stringent hygienic practices for sanitary processing. The CIP System utilizes fixed or retractable CIP spray nozzles that are designed specifically to remain in place during production. These nozzles minimizes downtime and increases available production time.

Multi zone Tema Fluidbed dryer

This type of Fluid bed system has several inlet and exhaust air compartments, each of which is equipped with its own supply air system (heating or cooling). Process parameters for each zone (temperature and flow) can therefore be adjusted to provide maximum control of the process and product characteristics. The system can handle multiple recipes with varying process parameters. A multi-zone shaking fluid bed dryer [...]

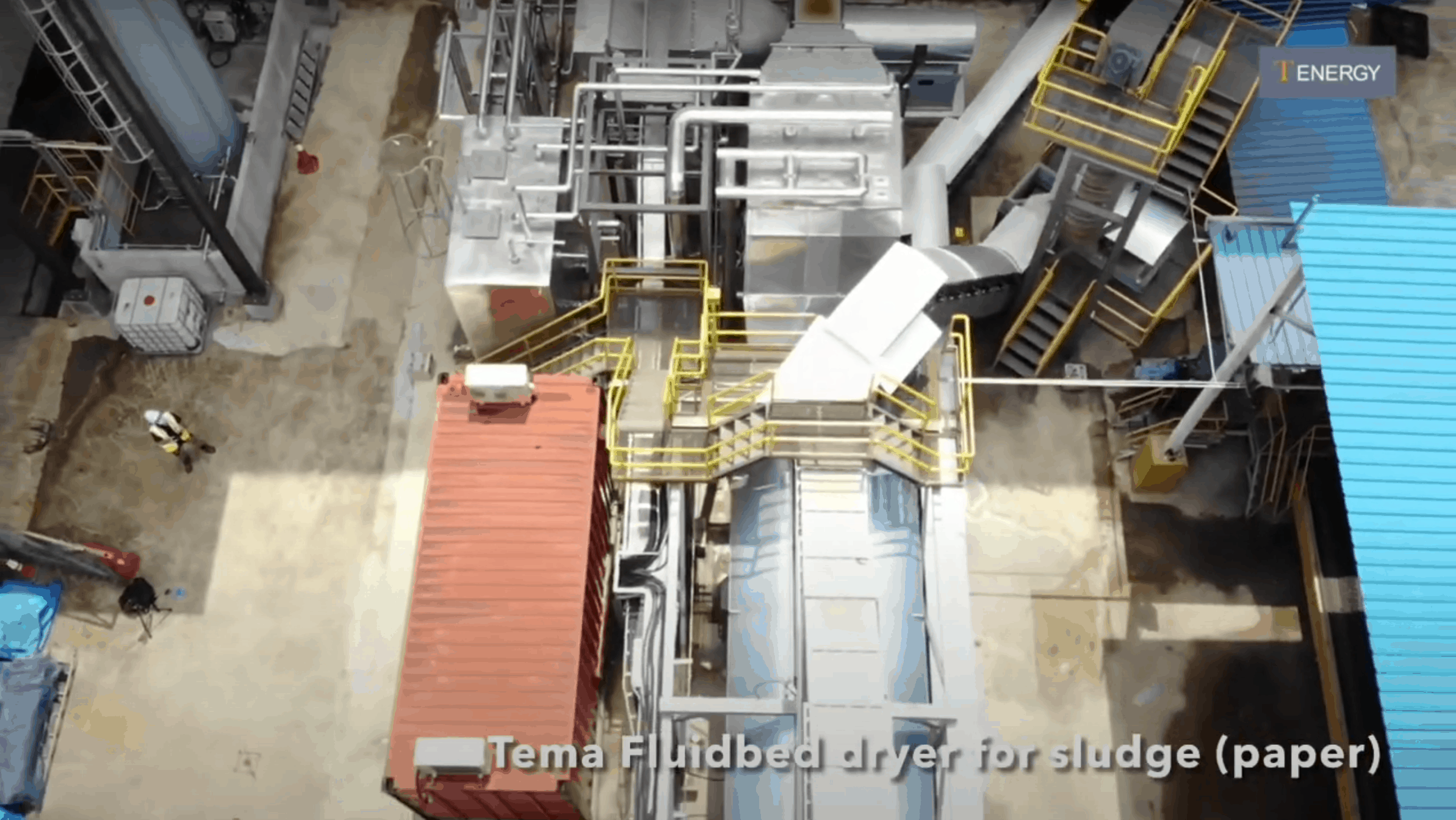

Tema Fluidbed dryer for sludge (paper)

Tema Fluidbed dryer for sludge (paper) […]

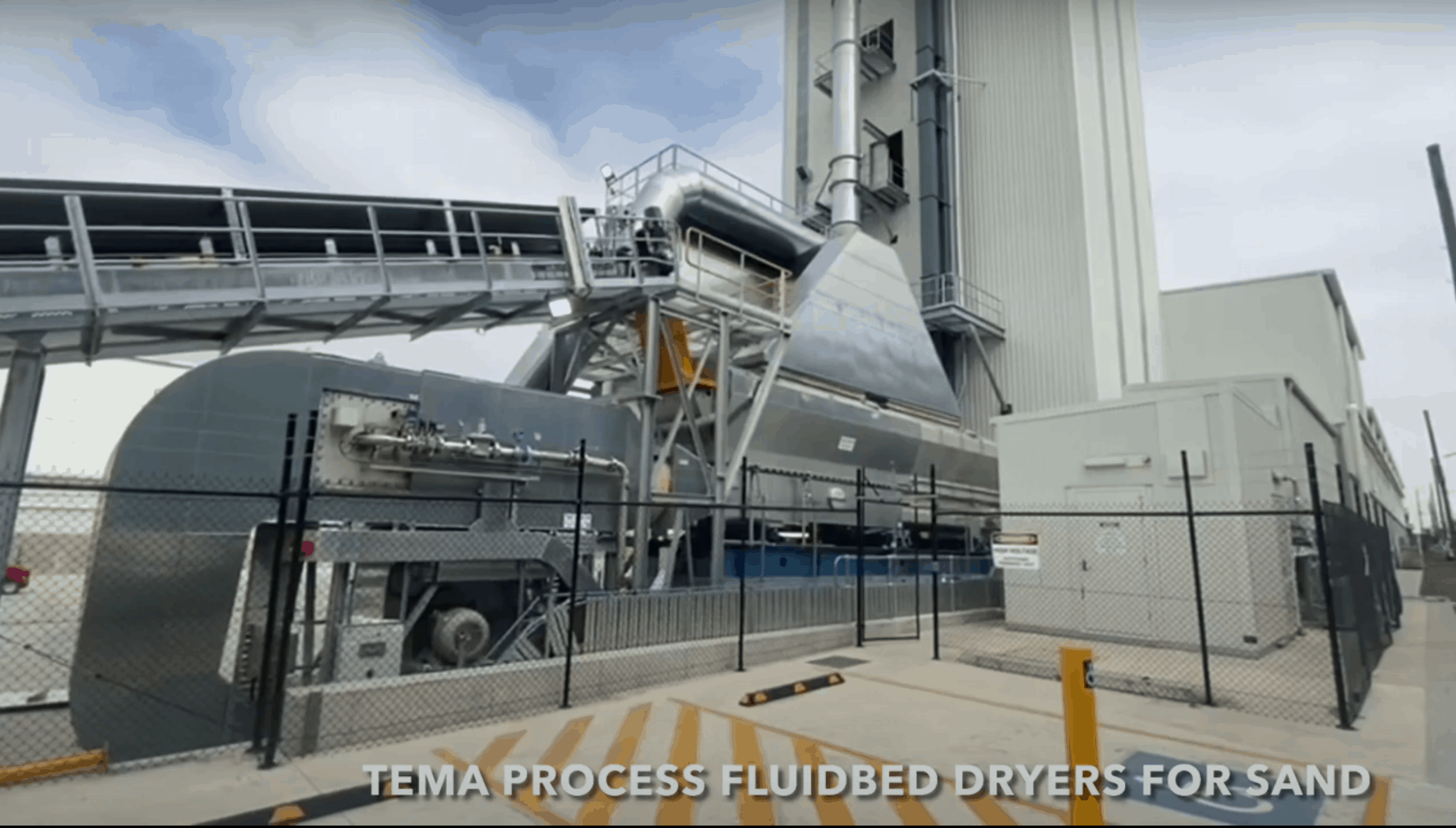

Tema Process – Sand Dryers

Energy savings with Tema Process sand dryers. Dryers are available from 2 t/h up to 200 t/h. […]

Back Mix – Fluid Bed Dryer

Back Mix System for Fluid Bed Dryers: The back mix system is used for materials that can not fluidise due to the high moisture content of the material. Sticky material, wetcake from the filter press, slurry, sludge or even a solution is mixed with dried product. This back mix flow enables better fluidisation and drying. The fluid bed dryer dries the material at low temperatures [...]

Fluidized Bed Dryers/Coolers for the food/feed industry

Fluidized Bed Dryers/Coolers for the food/feed industry: Bread crumb • Rusk • Croutons • Soy • Starch • Citric acid • Animal Feed • Baby food • Baking additive • Bread waste • Cacao • Casein • Chicken meat • Chocolate • Coffee • Coffee granulates • Corn flour • Dextrose • Edible fat • Egg powder • Flavours • Flour • Fruit products • [...]

Fluid Bed Dryer for Salt / Fertilizer

Generally, many salts are used as sources to produce agricultural fertilizers. Potassium is one of the basic chemical ingredients used for promoting plant growth. Refined potash salts, obtained from either ores or brines, are the only economically significant sources of potassium used in fertilizers. Soluble salt minerals comprise a variety of industrially significant materials including KCl, NaCl, KNO3 and NaNO3. Alkali sulfates such as K2SO4 [...]

The TEMA Process Pulse Jet Baghouse dust collector.

The TEMA Process Pulse Jet Baghouse dust collector (for the fluid bed dryer) provides easy and dependable operation for high-volume dust collection applications. An enormous number of construction variations are possible considering the variables in number of covers, number of bags in the length rows and filter bags length. The bags are protected by standard wear protection shields. Bag filter cleans itself by means of [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety