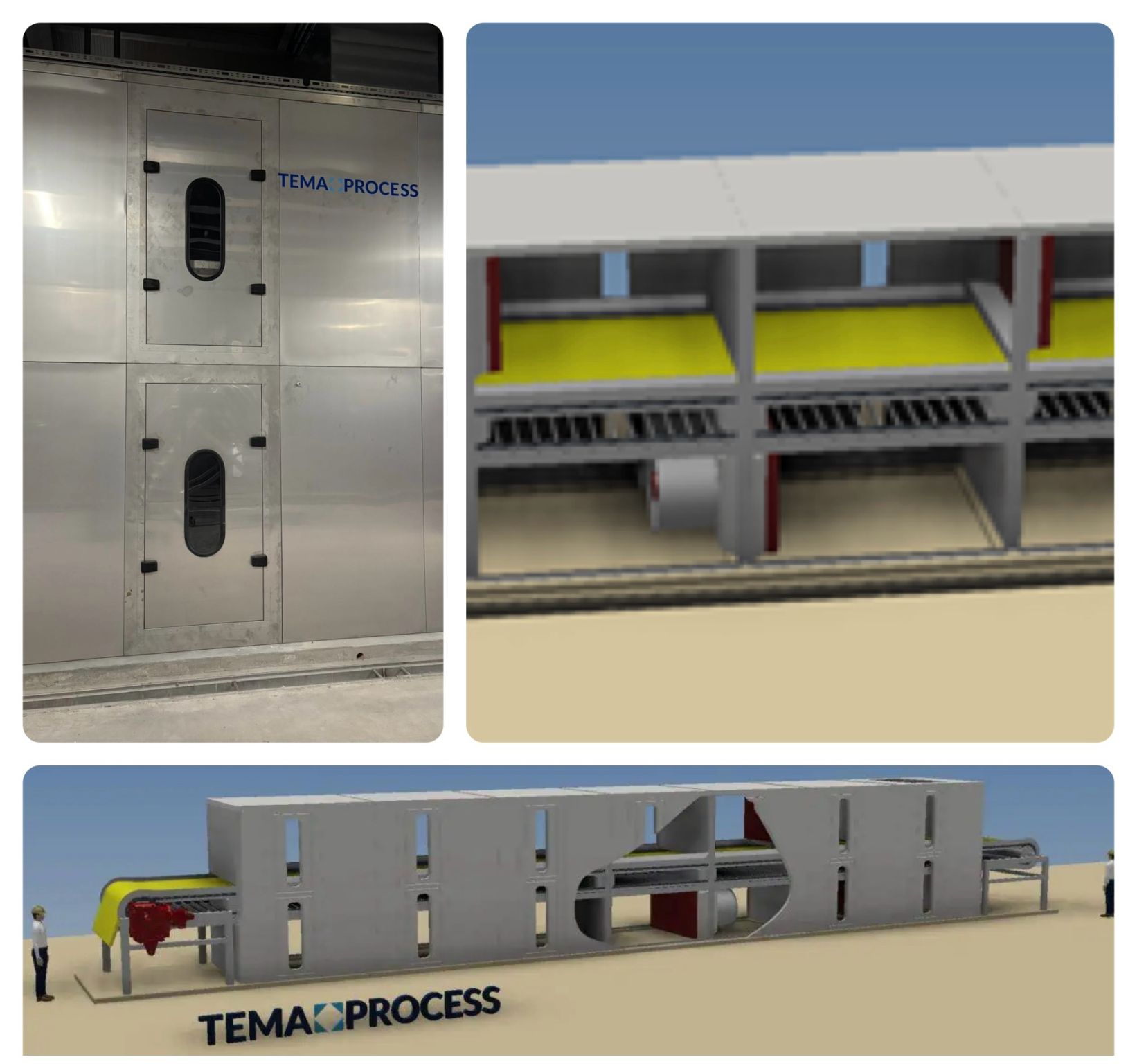

Transport of TEMA Breadcrumb dryer

Breadcrumb, rusk or Japanese processing lines: Breading’s typically contain seasonings and are applied as coatings to fried or baked foods to achieve certain textures, colours, and flavours. Rusk is used as a filler or a binding agent in hamburgers and sausages. Breadcrumb is made in either loaves/bricks/sheets or extruded onto a baking belt. The Tema bread crumb or rusk line consists of a bread mill, [...]

Drying Chemicals

Tema Process Fluidized bed systems are commonly used for drying and cooling a wide range of chemicals, powders, and granules. The suitability of a material depends on factors such as particle size, moisture content, and thermal stability. Chemicals That Can Be Dried or Cooled Using a Fluid Bed System 1. Inorganic Chemicals • Sodium carbonate (soda ash) • Sodium bicarbonate • Calcium carbonate • Ammonium [...]

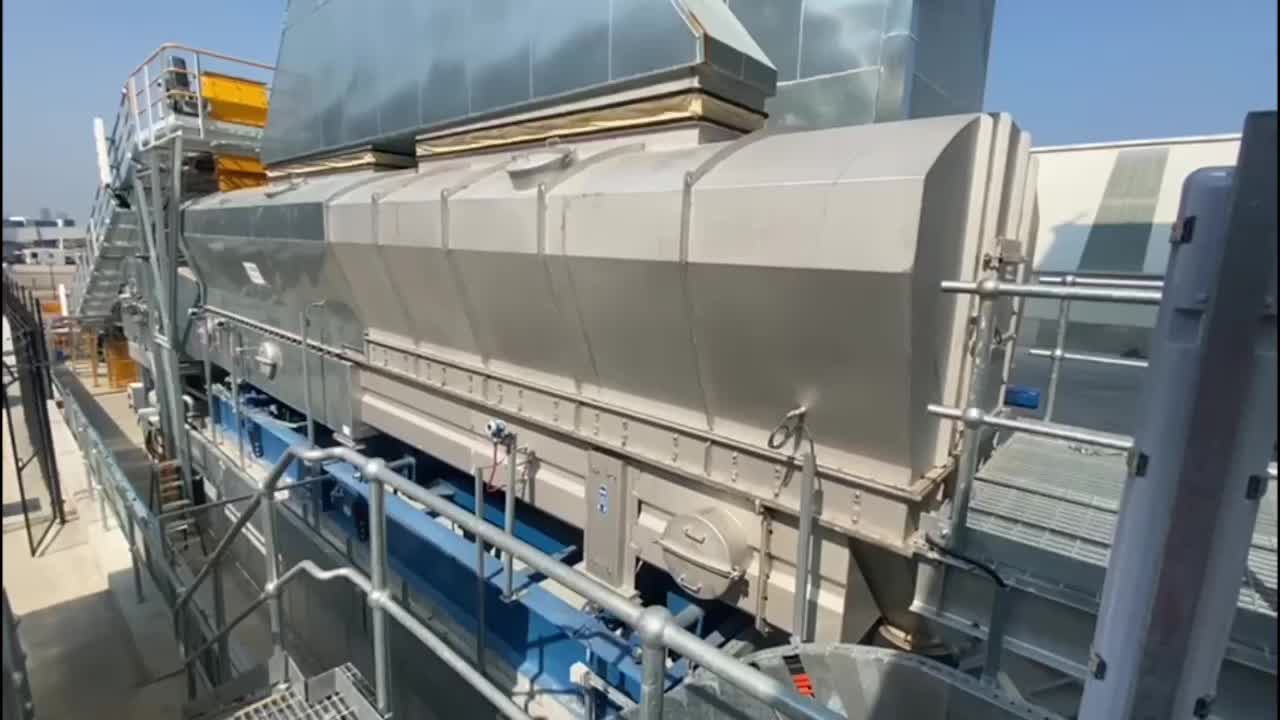

Sand dryer with heat recovery system

Erection and commissioning of a Tema Process sand dryer with heat recovery system. Sand is often dried for several practical reasons across different industries and applications. 1. Construction • Consistency: Dry sand is easier to measure and mix accurately with cement and other materials. Moist sand can cause inconsistencies in ratios. • Storage: Wet sand can clump together, making it difficult to transport and use [...]

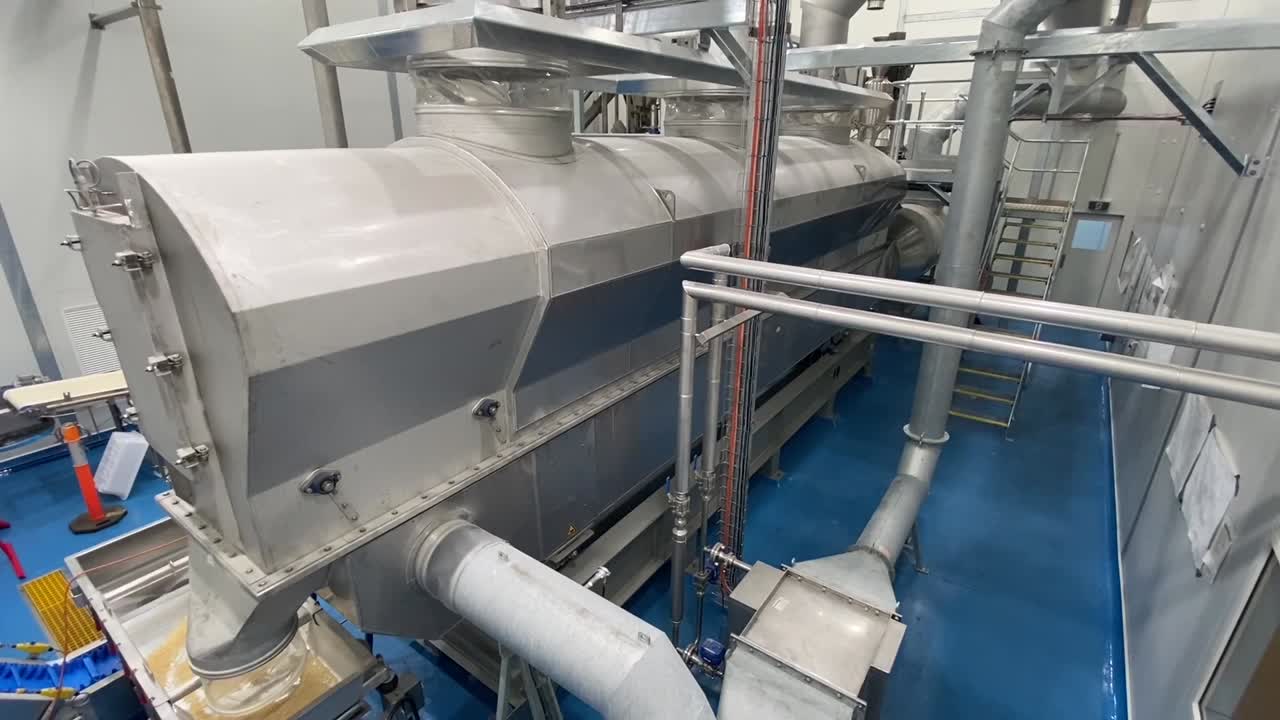

Gelatin belt dryer with dehumidifier

The gelatin belt dryer with a dehumidifier by TEMA Process is regarded as one of the best systems for gelatin drying due to its advanced technology, precision control, and reliable performance. Here’s why the TEMA Process belt dryer stands out: 1. Advanced Dehumidification Technology • TEMA Process integrates highly efficient dehumidification systems into their belt dryers. By continuously removing moisture from the drying air, the [...]

Fluid bed dryer for TVP

Textured or texturized vegetable protein (TVP), also known as textured soy protein (TSP), soy meat, or soya chunks, is a defatted soy flour product that results from the process of extracting soybean oil. It can also be produced from cotton seeds, wheat, and oats. TVP is formed into various shapes (such as chunks, flakes, nuggets, grains, and strips) through extrusion, expanding as it exits the [...]

LiOH, Li2CO3 and Na2SO4 dryers ready for transport

Lithium hydroxide (LiOH) enables the production of batteries for electric vehicles (EVs). Spodumene is a mineral consisting of lithium aluminium inosilicate, LiAl(SiO3)2, and is a source of lithium. In the production process lithium hydroxide and sodium sulphate is produced. After separating the solid and liquid by a centrifugal machine the lithium hydroxide (LiOH ) is dried on a Tema Process Fluid bed dryer. Also the [...]

Dryers for sand

Drying sand Typically, sand is mined, washed and screened and stored in piles with various grades. The sand needs to be dried to the required moisture content before it can be sold or further processed. Silica sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules. Silica sand is the primary component of all types [...]

Drying Processes for Black Soldier Fly Larvae

Optimizing Drying Processes for Black Soldier Fly Larvae Using Fluidized Bed Dryers with Plug Flow. Introduction. Black Soldier Fly (BSF) larvae have gained significant attention in recent years due to their versatile applications in waste management, animal feed production, and even human consumption. One critical aspect of utilizing BSF larvae is the drying process, which plays a crucial role in preserving their nutritional value and [...]

Sodium sulfate – Fluid Bed Dryer

Sodium sulfate (sulfate of soda , Na2SO4). The largest use is as filler in powdered home laundry detergents. It can also be used to add strength and toughness to paper and to make glass. During the drying process the bed temperature is uniform and the drying takes place at relative low temperatures. The fluidized bed drying is known as a drying method capable of efficiently [...]

Ammonium Sulfate – Fluid Bed Dryer

Ammonium Sulfate / (NH4)2SO4 - TEMA Process Fluid Bed Dryer Ammonium Sulfate (Ammonium sulphate, (NH4)2SO4), is an inorganic salt with a number of commercial uses. The most common use is as a soil fertilizer. Ammonium sulfate crystals are formed by circulating the ammonium sulfate liquor through a water evaporator, which thickens the solution. Ammonium sulfate crystals are separated from the liquor in a centrifuge. The [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety