Fluidized bed drying; one of the well-known and versatile methods

Out of various drying techniques, fluidized bed drying is one of the well-known and versatile methods. It is known for its uniform drying and high efficiency, hence is well adopted for industrial drying. However, drying agro-products using fluidized bed dryers is an emerging trend. It is proven to be energy efficient and causes minimal quality variation of dried products compared to other drying techniques. A [...]

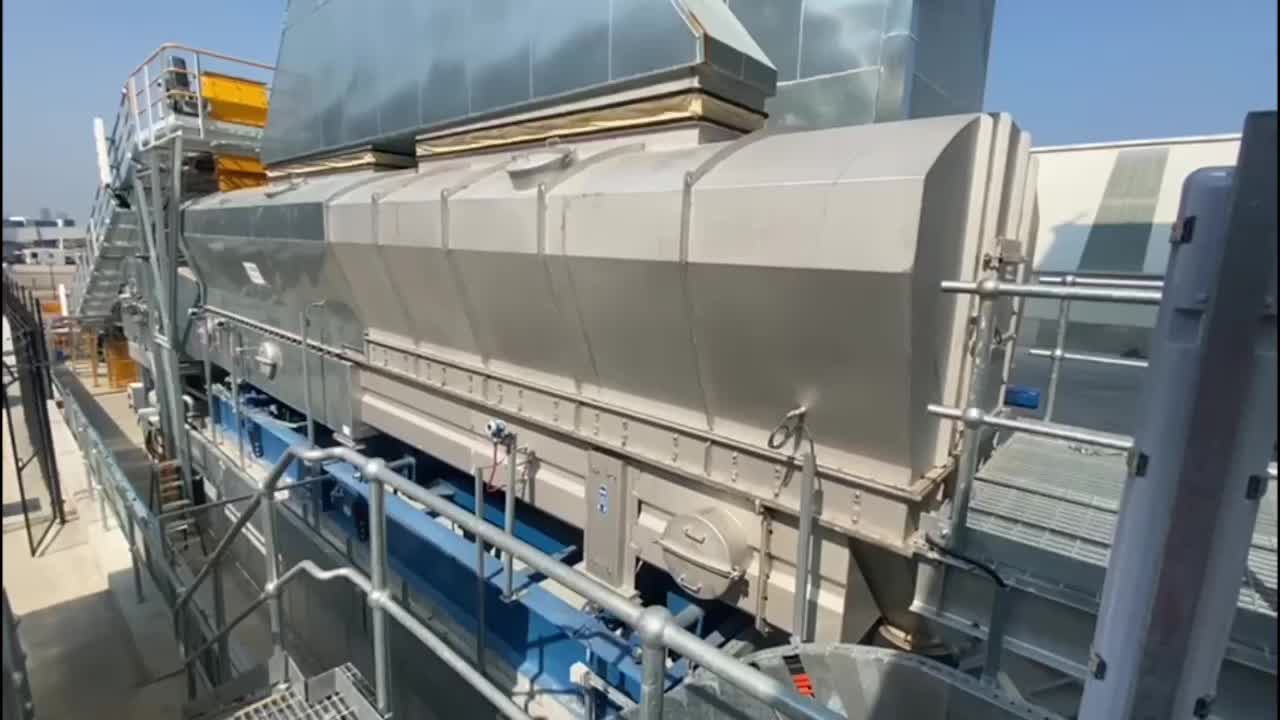

Dryers for sand

Drying sand Typically, sand is mined, washed and screened and stored in piles with various grades. The sand needs to be dried to the required moisture content before it can be sold or further processed. Silica sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules. Silica sand is the primary component of all types [...]

Fluidbed dryers / coolers

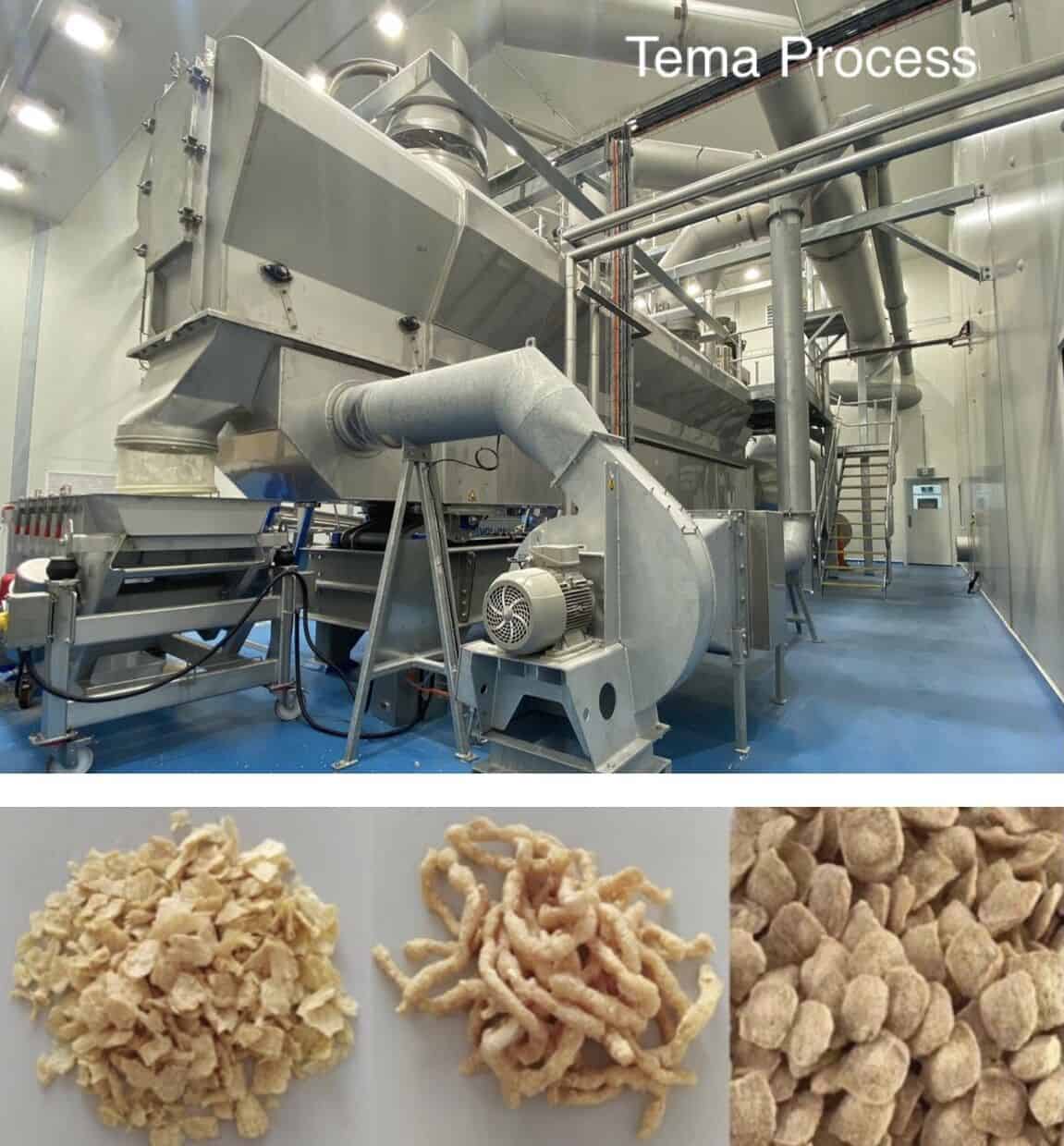

The sanitary execution Tema Process Fluidbed dryers / coolers have a hygienic single hull design (bedplate, windbox and suction hood are welded together) and are equipped with a Washing-In-Place (WIP) system. The WIP is an automated system used to clean the interior surfaces of the fluid bed dryer ducting etc. […]

Sodium sulfate – Fluid Bed Dryer

Sodium sulfate (sulfate of soda , Na2SO4). The largest use is as filler in powdered home laundry detergents. It can also be used to add strength and toughness to paper and to make glass. During the drying process the bed temperature is uniform and the drying takes place at relative low temperatures. The fluidized bed drying is known as a drying method capable of efficiently [...]

Ammonium Sulfate – Fluid Bed Dryer

Ammonium Sulfate / (NH4)2SO4 - TEMA Process Fluid Bed Dryer Ammonium Sulfate (Ammonium sulphate, (NH4)2SO4), is an inorganic salt with a number of commercial uses. The most common use is as a soil fertilizer. Ammonium sulfate crystals are formed by circulating the ammonium sulfate liquor through a water evaporator, which thickens the solution. Ammonium sulfate crystals are separated from the liquor in a centrifuge. The [...]

Drying black soldier fly larvae and mealworms on a fluidized bed dryer offers several advantages

Animal Feed Mealworms and black soldier fly larvae are commonly used as a sustainable and nutritious alternative in animal feed. They are rich in proteins, healthy fats, and other essential nutrients, making them suitable for livestock, poultry, fish, and pet food. Waste Management Mealworms and black soldier fly larvae are excellent decomposers and can help in waste management. They can efficiently convert organic waste, such [...]

Recovered Carbon Black Fluidized Bed Dryer with ATEX Certification

In recent years, there has been a growing emphasis on sustainability and environmental responsibility in various industries, including the tire manufacturing sector. One aspect of sustainable tire production is the efficient recovery and reuse of carbon black, a crucial component in tire manufacturing. To facilitate this process, companies have developed advanced technologies, such as recovered carbon black fluidized bed dryers, which offer significant advantages when [...]

Fluidized bed dryer

Fluidized bed dryer (also called fluid bed dryer) is equipment used extensively in the bulk industry to reduce the moisture content of powder and granules. The equipment works on a principle of fluidization of the feed materials. In the fluidization process, hot air is introduced at high pressure through a perforated bed plate. The wet solids are lifted from the bed plate and suspended in a [...]

Drying of Extruded food & feed products

Extrusion is a mechanical process in which food or feed materials are forced, under pressure, through a die opening to create products of a desired shape, size, and/or texture. In the case of food production, if the food is heated by external heaters during the process, it is referred to as extrusion cooking, a relatively new and advanced food processing technique. Due to its processing [...]

Fluid bed drying

Fluid bed drying is a process by which particles, typically greater than 100 microns, are fluidized and dried. For the material to become fluidized, the particulates are placed under conditions that cause it to behave like a fluid. In a fluid bed drying system, air is passed through a perforated distributor plate which provides significant air flow to support the weight of the particles. This [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety