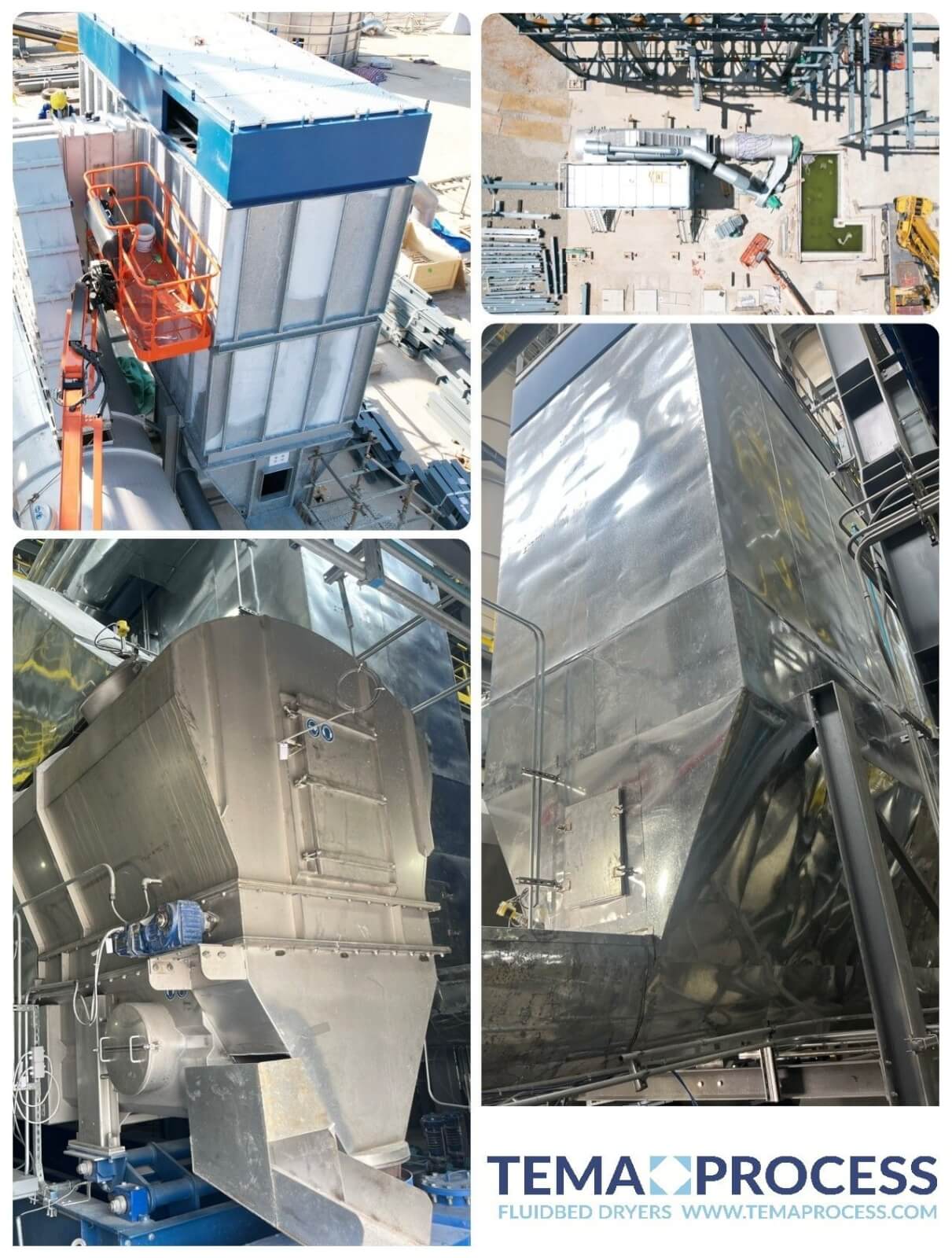

Erection and Commissioning of a Fluid Bed Dryer/Cooler for Minerals.

Successfully completed the erection and commissioning of a fluid bed dryer/cooler for mineral processing. The scope included mechanical installation, electrical and instrumentation works, and comprehensive pre-commissioning activities. Following installation, dry commissioning was carried out to verify airflow, temperature control, and safety systems. Operational commissioning with mineral material allowed optimisation of process parameters to achieve stable fluidisation and reliable drying and cooling performance. The project was [...]

Why are minerals dried in a Tema Process fluid bed dryer?

For minerals like sand, gypsum, talc, salts, clays and limestone, a Tema Process fluid bed dryer offers industry-leading performance and product quality. - Uniform and consistent drying Our fluidization technology ensures perfect heat transfer and stable final moisture — no hot spots, no overdrying. - High energy efficiency Tema Process systems are designed with optimized airflow, low pressure drop and optional heat recovery, delivering one [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety