Tema Process Sodium Chloride Dryer/Cooler

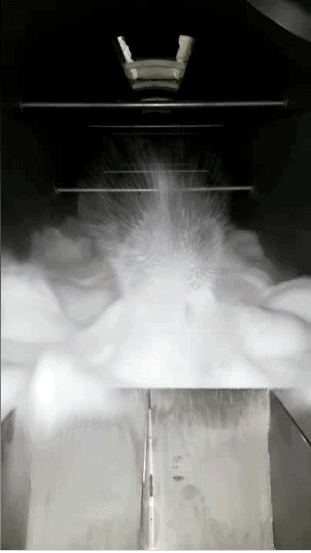

Video of Sasko Algeria Salt NaCl Drying/Cooling […]

Fluid bed dryer for salt

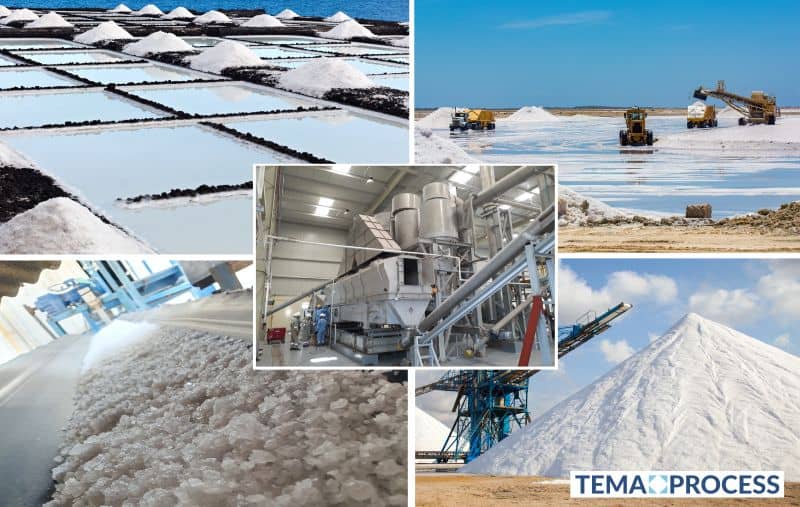

Sea salt is salt produced from the evaporation of seawater. Its use is practical only in warm climates where the evaporation rate exceeds the precipitation rate, either annually or for extended periods, and ideally, where there are steady prevailing winds. When an adequate layer of salt has built up on the pan floor, harvesting commences. A machine digs up the salt, deposits it onto a conveyor [...]

Salt Drying

Tema Process is the liquid/solid separation solution provider for Salt production and processing plants. Salt is the common name for the substance sodium chloride (NaCI), which occurs in the form of transparent cubic crystals. Salt centrifuge The Siebtechnik Tema centrifuges are used for continuous solid-liquid separation and provide a long holding time, low material loss and low crystal breakage. The centrifuge enables the salt to [...]

Salt centrifuge & drying

Tema Process is the liquid/solid separation solution provider for Salt production and processing plants. Salt is the common name for the substance sodium chloride (NaCI), which occurs in the form of transparent cubic crystals. Salt centrifuge The Siebtechnik Tema centrifuges are used for continuous solid-liquid separation and provide a long holding time, low material loss and low crystal breakage. The centrifuge enables the salt to be dewatered [...]

Tema Process Sea Salt Dryer

Production of sea salt begins with evaporation of sea water in shallow pools and ends with the harvest, washing, drying and packing of salts. […]

Tema Process has developed a new range of industrial-grade and pharma-grade salt fluid bed dryers

Salt is extremely soluble in water. Sea, ocean water or salt brines are the major sources of the world supply of salt. The recovery of salt from sea/brine water occurs by the evaporation of water and until the salt begins to crystallize. Crystallization occurs when the concentration of a chemical exceeds the solubility in the particular solvent. Brine (salt water) is chemically purified and by [...]

Sodium Sulfate drying using Fluid bed dryers

Sodium Sulfate Na2SO4 drying. Fluid bed dryers are today's standard of technology for drying and cooling of all kind of salts. Sodium Sulfate: the largest use is as filler in powdered home laundry detergents, consuming approx. 50% of world production. The glass industry provides another significant application for sodium sulfate.

Salt drying. Commissioning a Tema Process dryer/cooler

Salt drying. Commissioning a Tema Process dryer/cooler. In solution mining, salt is extracted by forcing water under pressure into a bore-hole drilled into an underground salt bed or dome. The salt dissolves, turning the water into brine and creating a cavern in the salt-bed. The salt is produced by evaporating ‘solution-mined’ brine in pressure vessels – a process known as Vacuum Evaporation. For food and [...]

advanced fluid beds for salt drying applications

Salt, or Sodium Chloride, is essential for life , weather for human beings or animals, and it’s history for production goes back a long time. Weather produced by natural evaporation in ponds, or mined as rock salt, in the upgrading process to clean salt crystals, salt drying is a crucial step. Tema Process supplies advanced fluid beds for salt drying applications ( sea-salt, rock salt [...]

Salt drying

Salt Drying. Weather produced by natural evaporation in ponds, or mined as rock salt, in the upgrading process to clean salt crystals, salt drying is a crucial step. Tema Process supplies advanced fluid beds for salt drying applications ( sea-salt, rock salt , vacuum salt or brines) in a large range of capacities , manufactured in corrosion resistant AISI-316 and other grades. Smart designs for [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety