Why are minerals dried in a Tema Process fluid bed dryer?

For minerals like sand, gypsum, talc, salts, clays and limestone, a Tema Process fluid bed dryer offers industry-leading performance and product quality. - Uniform and consistent drying Our fluidization technology ensures perfect heat transfer and stable final moisture — no hot spots, no overdrying. - High energy efficiency Tema Process systems are designed with optimized airflow, low pressure drop and optional heat recovery, delivering one [...]

Fluidized Bed Dryer for Sand

A Tema fluidized bed dryer (also known as a fluid bed dryer) is commonly used in industries for drying particulate materials like sand due to its efficiency and uniformity. Here are the main advantages of using a fluidized bed dryer specifically for drying sand: Advantages of Fluidized Bed Dryer for Sand 1. Efficient Heat and Mass Transfer The fluidization of sand particles allows maximum contact [...]

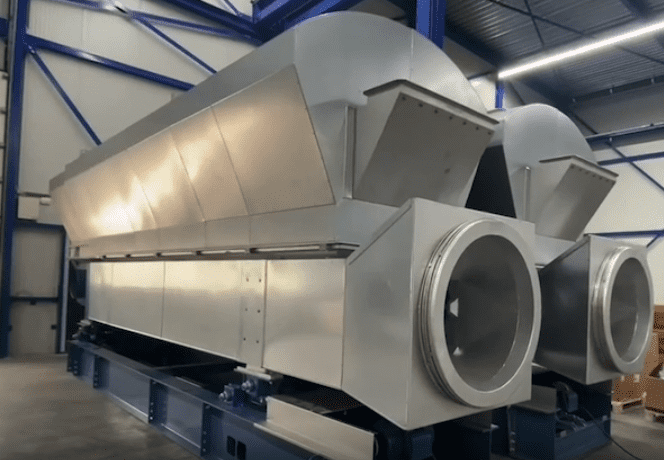

Transport of a Sand dryer with energy recovery

High temperature drying at up to 600°C: This results in greater evaporation per square metre of bed without an increase in air volume, reduces the power consumption per tonne of sand dried and improves fuel efficiency. The TEMA Fluid Bed dryer is split into two sections, the first of which operates at a high temperature (up to 600°C). In the first stage of drying, free [...]

Sand dryer with heat recovery system

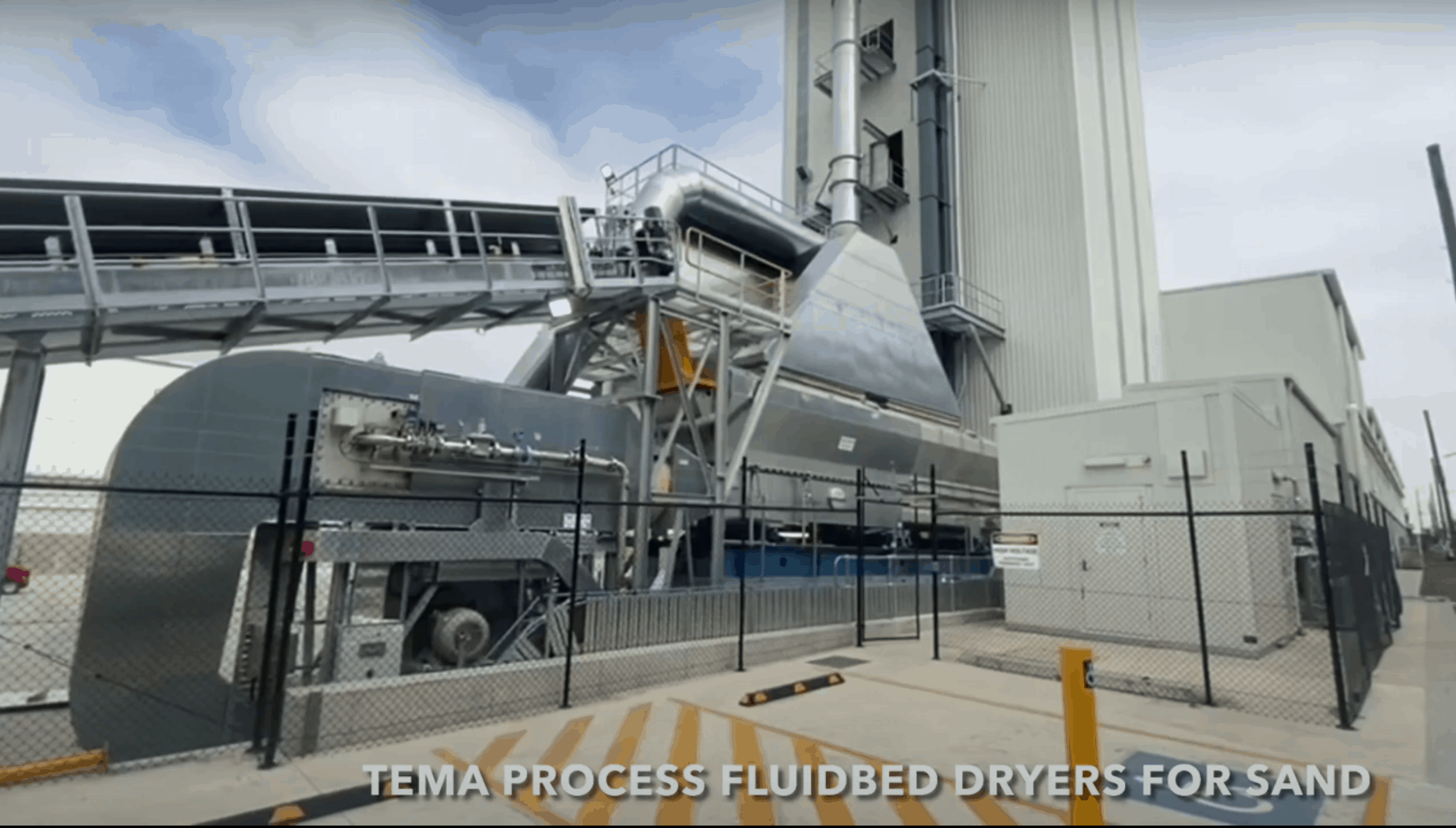

Erection and commissioning of a Tema Process sand dryer with heat recovery system. Sand is often dried for several practical reasons across different industries and applications. 1. Construction • Consistency: Dry sand is easier to measure and mix accurately with cement and other materials. Moist sand can cause inconsistencies in ratios. • Storage: Wet sand can clump together, making it difficult to transport and use [...]

Dryers for sand

Drying sand Typically, sand is mined, washed and screened and stored in piles with various grades. The sand needs to be dried to the required moisture content before it can be sold or further processed. Silica sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules. Silica sand is the primary component of all types [...]

Drying of slag sand

Slag is a by-product of smelting (pyrometallurgical) ores and used metals. The meaning of slag sand is slag crushed into fine particles and is used especially in mortar or concrete. Slag sand is a good alternative to river sand, say experts. The uses of industrial waste as a substitute material helps save a large share of natural resources and protect the environment. Slag sand is [...]

Fluid Bed Dryer for Sand

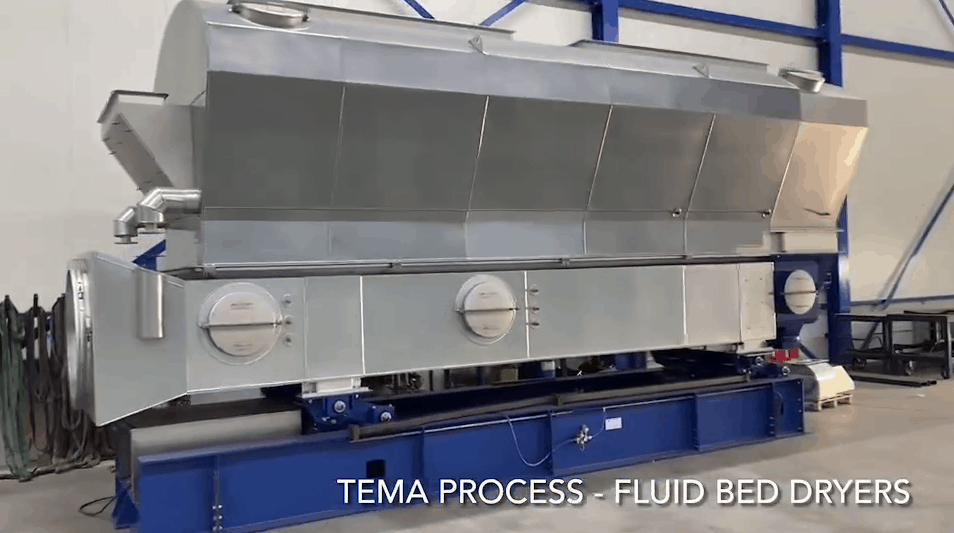

Sand drying: a fluid bed dryer processes granular, free-flowing materials include sand, minerals, clays, etc. In a fluid bed, the material being dried is suspended and completely surrounded by the drying air or gas, causing that material to behave like a fluid. Besides keeping the material in a seemingly liquid state, the gas stream is the media for heat and mass exchange. As a result [...]

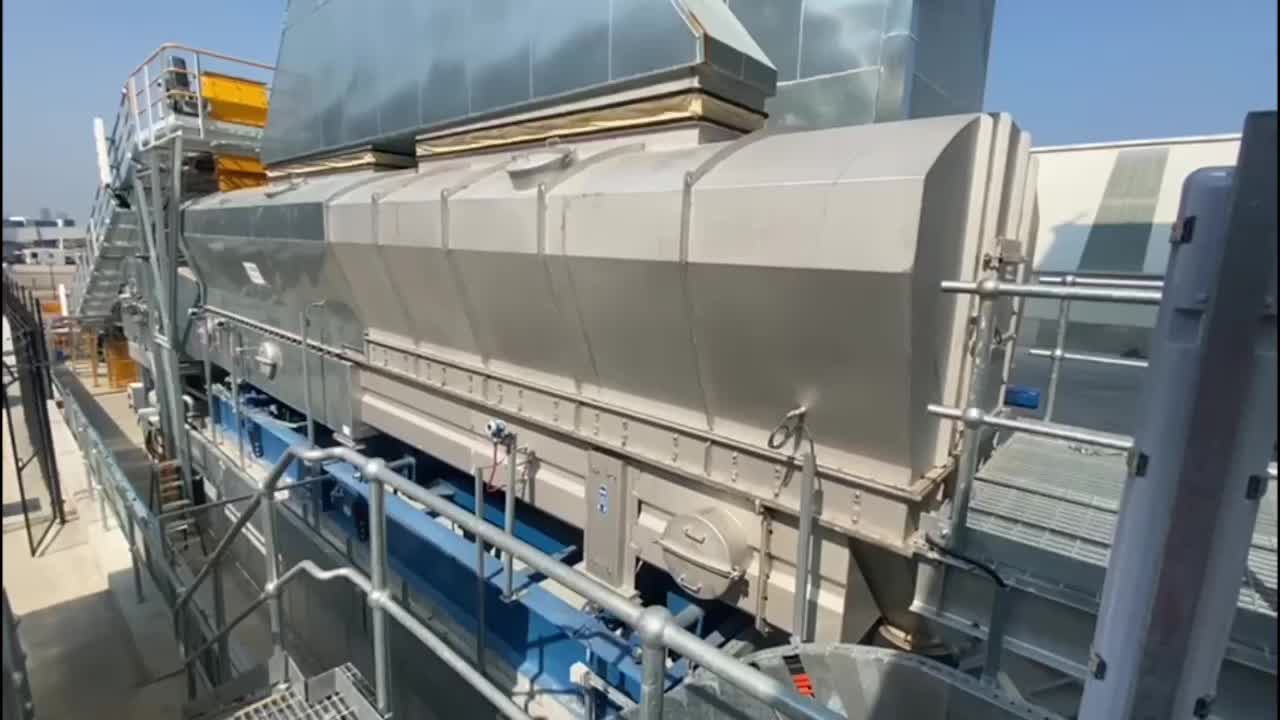

Sand Dryers for India – Ready for shipment

Tema Process is the leading international manufacturer of fluidbed drying systems. The company owes its strong growth to consistently delivering high quality consultancy, process improvements and efficient tailor-made solutions for a range of industrial sectors, including the food, feed, chemicals, minerals and recycling industries.

Tema Process – Sand Dryers

Energy savings with Tema Process sand dryers. Dryers are available from 2 t/h up to 200 t/h. […]

Foundry sand dryer with gas burner

Foundry sand dryer with gas burner – ready for dispatch. Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term “sand casting” can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 60% of all metal castings are produced via [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety