Successful commissioning of our new gelatin belt dryer

We are excited to announce the successful commissioning of our new gelatin belt dryer. A Tema gelatin dryer is designed to remove moisture from gelatin after the extraction and filtration processes. The drying process must be carefully controlled to preserve the quality, texture, and purity of the final product. Using warm, dry air, the gelatin is typically dried on a belt dryer, reducing moisture to [...]

Transport of TEMA Breadcrumb dryer

Breadcrumb, rusk or Japanese processing lines: Breading’s typically contain seasonings and are applied as coatings to fried or baked foods to achieve certain textures, colours, and flavours. Rusk is used as a filler or a binding agent in hamburgers and sausages. Breadcrumb is made in either loaves/bricks/sheets or extruded onto a baking belt. The Tema bread crumb or rusk line consists of a bread mill, [...]

Drying Chemicals

Tema Process Fluidized bed systems are commonly used for drying and cooling a wide range of chemicals, powders, and granules. The suitability of a material depends on factors such as particle size, moisture content, and thermal stability. Chemicals That Can Be Dried or Cooled Using a Fluid Bed System 1. Inorganic Chemicals • Sodium carbonate (soda ash) • Sodium bicarbonate • Calcium carbonate • Ammonium [...]

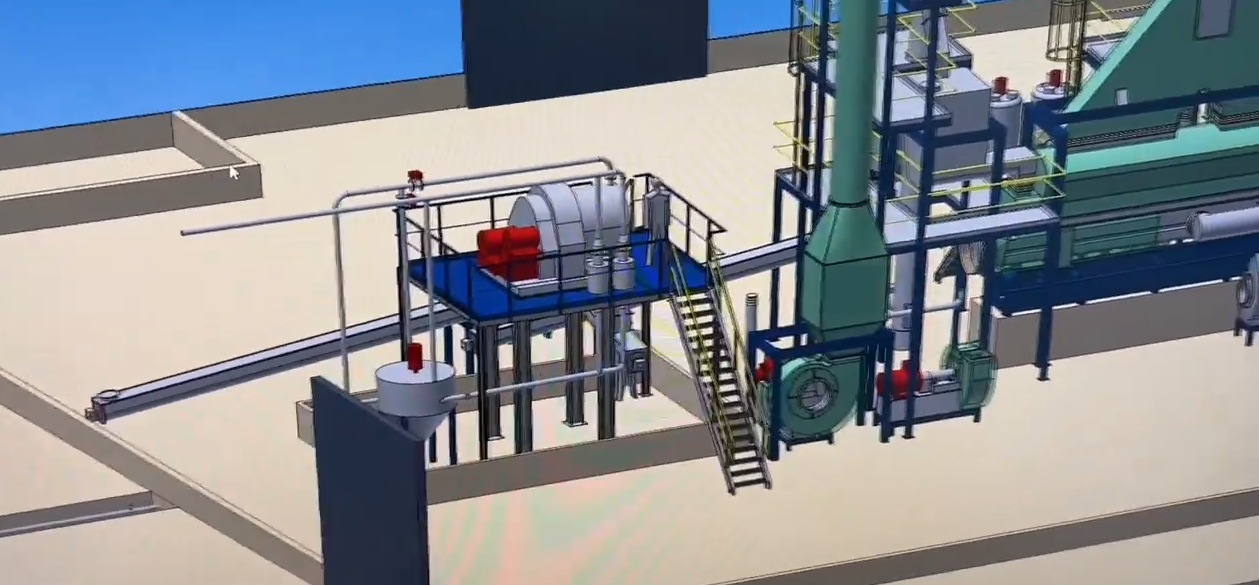

Steam Sterilization vs. EtO for Spices: The Safer Choice

Steam Sterilization vs. EtO for Spices: The Safer Choice Across the globe, food producers and regulators are moving away from ethylene oxide (EtO) due to its toxic residues, environmental impact, and growing bans in regions like the EU and Japan. Tema Process Steam Sterilization stands out as a clean, natural alternative that leaves no chemical residues, meets organic standards, and aligns with consumer demand for [...]

Multi-temperature zones in a fluid bed dryer

Multi-temperature zones in a Tema Process fluid bed dryer are used to optimize the drying process by providing better control over moisture removal, product quality, and energy efficiency. Here’s why they are beneficial: 1. Optimized Drying Stages – Different materials require gradual drying to prevent surface hardening or uneven drying. Multi-zone dryers allow initial high-temperature drying followed by lower-temperature zones for controlled moisture removal. 2. [...]

The proces of drying and washing sea salt

The sea salt washing and drying process is essential to produce clean, high-quality salt suitable for consumption and industrial use. Here’s a general overview of the process: 1. Harvesting the Sea Salt • Sea salt is typically harvested from salt pans or evaporation ponds where seawater has been left to evaporate, leaving behind crystallized salt. • The harvested salt often contains impurities such as sand, [...]

Fluidized bed drying; one of the well-known and versatile methods

Out of various drying techniques, fluidized bed drying is one of the well-known and versatile methods. It is known for its uniform drying and high efficiency, hence is well adopted for industrial drying. However, drying agro-products using fluidized bed dryers is an emerging trend. It is proven to be energy efficient and causes minimal quality variation of dried products compared to other drying techniques. A [...]

Sodium sulfate Na2SO4 dryer and Bread crumb dryer ready for transport

Tema Fluid Bed Systems for drying of minerals, chemicals, food, feed, biomass, etc. The TEMA Fluid Bed can be applied not only for drying, but also for cooling, roasting, torrefaction, puffing, blanching, stripping, spices and herbs sterilisation and pasteurisation and calcining.

Transport of a Sand dryer with energy recovery

High temperature drying at up to 600°C: This results in greater evaporation per square metre of bed without an increase in air volume, reduces the power consumption per tonne of sand dried and improves fuel efficiency. The TEMA Fluid Bed dryer is split into two sections, the first of which operates at a high temperature (up to 600°C). In the first stage of drying, free [...]

Sub-Fluid Bed Dryer for Black Soldier Fly Larvae Drying

Sub-Fluid Bed Dryer for Black Soldier Fly (BSF) Larvae Drying: An Efficient Solution for Insect Protein Processing The drying of Black Soldier Fly (BSF) larvae is a critical step in the insect protein production process. Proper drying not only ensures product stability but also preserves the nutritional value of the larvae, making them suitable for use in animal feed and pet food. The sub-fluid bed [...]

Tags

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety