Shaking fluid bed dryer versus vibrating fluid bed dryer

At TEMA Process we use a more advanced technique, eliminating the disadvantages of a vibrating fluid bed dryer.

Vibrating fluid bed dryers

Vibrating fluid bed dryers use a large drive mechanism with the bed mounted on springs like a vibrating conveyor to move product through the dryer. The main disadvantage is that the dryer and the product are subjected to significant g-forces. These high forces typically cause friable product to break apart creating unnecessary and often unwanted fines and waste. In addition, the high g-forces will be transferred to the surrounding structures resulting in additional installation requirements, premature equipment wear, premature instrument wear and elevated noise. This causes the bed case to fracture and the drive mechanisms are subject to periodic refurbishment.

Tema Process Shaking fluid bed dryers:

Shaking fluid bed dryers solve the high g-force issue by eliminating the need for vibration and include a more advanced control systems that eliminates the need for continuous operator involvement. Product is moved through the dryer by a gentle shaking motion, Low Frequency / High Amplitude, which moves it forward in a step by step uniform manner referred to as plug flow. The g-force issue is eliminated allowing for smallest possible product deterioration, reduced foundation requirements and minimal noise output. A shaking fluid bed dryer system typically has the lowest life cycle cost via substantial savings in fuel consumption and maintenance costs.

Shaking fluidized bed dryers are well suited for:

- Material that has a wide particle size distribution — fluid bed dryer shaking will help to discharge oversize particles that will not fluidize.

- Sluggish or sticky materials.

- Temperature sensitive materials — a sub-fluidized condition can be created to produce plug flow and eliminate burning or discoloration of individual particles.

- Fragile materials — low amplitude fluid bed dryer shaking and reduced fluidizing velocity create a gentle bed, which causes less degradation than conventional fluid bed dryers or other mechanical dryers.

Features and benefits of shaking fluid bed dryers:

- Lower fluidizing velocities are required, making the fluid bed dryer system more energy efficient.

- Easy to clean and maintain.

- Re-circulated gas and closed-loop systems available for improved efficiency or solvent recovery.

- Clean-in-place and fire suppression systems available as part of the shaking fluid bed dryer, where necessary.

- Sanitary, U.S.D.A. (3A) approved shaking fluid bed dryer construction.

Advantages of shaking fluid-bed dryer systems

Advantages of shaking fluid-bed dryer systems

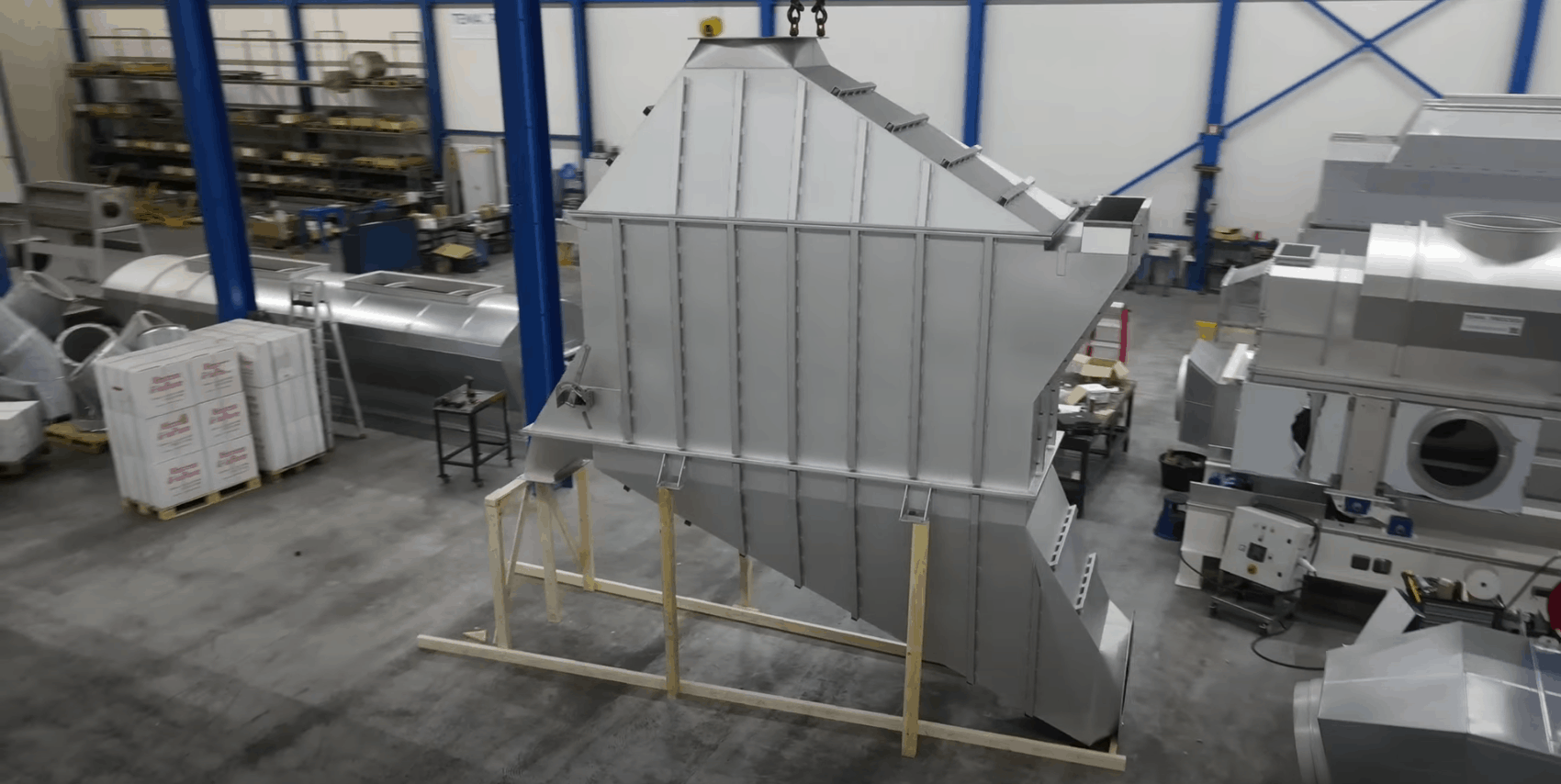

Our Tema Process Shaking fluid bed dryer in action

Shaking fluid bed dryers are frequently used for the drying of raw natural minerals or pre-processed minerals. The unique TEMA Process shaking drive mechanism allows for a uniform drying result for a large spread in particle size distribution ( 110 microns – 10 mm) , without disruptions of the fluid bed. This shaking design is suitable for capacities up to 100 t/h in a single unit.

Types of Fluid bed dryers

Fluid bed units

A fluid bed is an effective unit to thermally treat powders, crystalline products, pelletized or extruded materials. High heat and mass transfer are obtained as a result of the intimate contact between fluidizing air and product.

Shaking fluid bed

units for continuous operation and suitable for sticky materials with a wide particle size distribution. The shaking motion improves the fluidization and transport of any material within the fluid bed. Drying gas temperature up to 750 °C and product temperatures up to 400 °C are achieved

Static fluid bed

units in continuous and batch type for more uniform materials that do not tend to agglomerate. It is possible to install submerged heat exchangers in a deep static bed. With submerged heat exchangers energy input is both from the fluidizing air as well as from the heat exchangers reducing the size of the equipment and limiting the exhaust air volume.

Interested?

Exploring options for your process? TEMA Process is here to assist. Whether you have specific questions or need guidance in selecting the right solution, our experts are just a call or email away. Leave your contact details, and one of our specialized team members will promptly get in touch. They’ll provide you with all the necessary information about our advanced solutions, tailored to meet your unique requirements. Let TEMA Process be your partner in achieving optimal product quality and safety